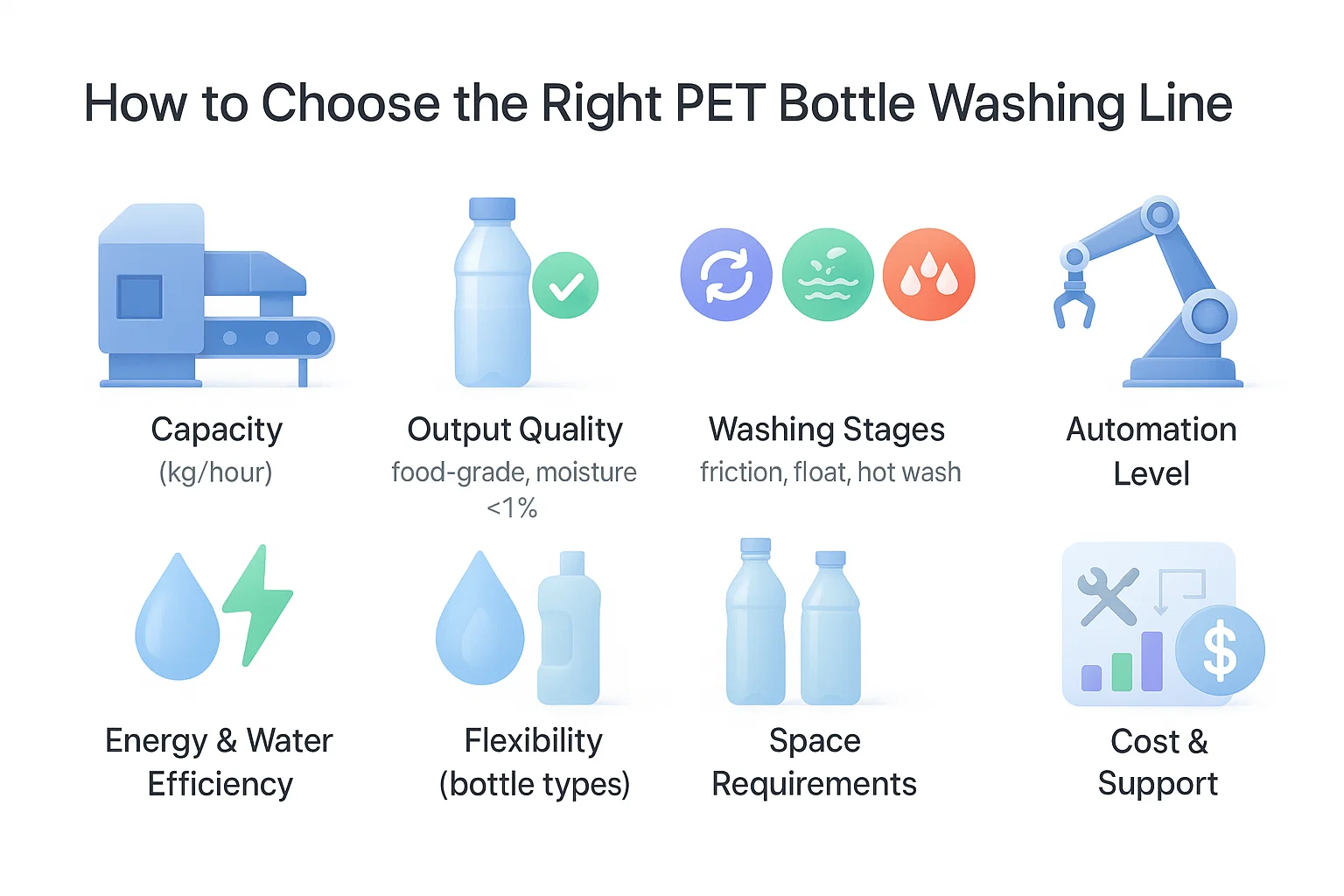

Selezionare il giusto Linea di lavaggio bottiglie PET è fondamentale per garantire una produzione efficiente, una qualità di output costante e il successo operativo a lungo termine. Che stiate entrando nel settore del riciclo o ampliando le vostre attività attuali, è essenziale considerare diversi fattori chiave per prendere una decisione informata.

1. Valuta la tua capacità di elaborazione

Inizia determinando la quantità di materiale PET (bottiglie o scaglie) che intendi processare all'ora o al giorno. Le linee di lavaggio in genere variano da da 500 kg/h a oltre 5000 kg/h, con soluzioni personalizzate che raggiungono 6000 kg/h o più.

Scegliere un sistema che si adatti alle tue reali esigenze produttive ti aiuterà a evitare le insidie del sottoutilizzo o del sovrainvestimento.

2. Definire la qualità di output richiesta

Considera se il tuo prodotto finale deve soddisfare standard di qualità alimentare, che richiedono elevata purezza e fasi di lavorazione aggiuntive come lavaggio a caldo E ordinamento avanzato.

Assicurare che il sistema fornisca costantemente fiocchi con basso contenuto di umidità (inferiore a 1%) e contaminazione minima, in particolare PVC, etichette o metalli.

3. Esaminare l'efficienza e la tecnologia di lavaggio

Le linee di lavaggio efficienti utilizzano un processo multi-fase Per massimizzare la pulizia e la qualità. Cerca sistemi che includano:

- Lavaggio a frizione

- Separazione galleggiante-affondante

- Lavaggio a caldo

- Separazione della densità

Queste tecnologie riducono la necessità di rielaborazione e aiutano a mantenere un output di alta qualità.

4. Considerare l'automazione e la facilità d'uso

L'automazione può migliorare significativamente la coerenza operativa e ridurre i costi di manodopera. Tuttavia, livelli di automazione più elevati possono comportare un maggiore investimento iniziale.

Seleziona un sistema che bilanci l'automazione con il tuo team competenze tecniche E capacità di manutenzione.

5. Valutare l'efficienza energetica e idrica

Scegli attrezzature progettate per ridurre al minimo il consumo di energia e acqua, che incidono direttamente sui costi operativi a lungo termine.

Gli stendibiancheria moderni spesso includono sistemi idrici a circuito chiuso E motori a risparmio energetico per migliorare la sostenibilità e ridurre gli sprechi.

6. Garantire flessibilità e adattabilità

Se i materiali di input variano (diverse dimensioni delle bottiglie, colori o livelli di contaminazione), scegli un sistema che possa adattarsi a materie prime diverse.

Le linee versatili migliorano il ROI e ti aiutano a rispondere prontamente alle mutevoli esigenze del mercato.

7. Considerare i requisiti di spazio e di installazione

Valuta attentamente la disposizione della tua struttura e seleziona le attrezzature adatte allo spazio disponibile. Molti produttori offrono layout personalizzati per ottimizzare lo spazio a terra e il flusso di lavoro senza compromettere le prestazioni.

8. Confronta i costi e l'assistenza post-vendita

Sebbene il costo iniziale dell'attrezzatura sia importante, bisogna considerare anche:

- Misure di prestazione

- Termini di garanzia

- Manutenzione e disponibilità dei ricambi

- Qualità del servizio post-vendita

La scelta di un fornitore affidabile garantisce continuità operativa a lungo termine e riduce i tempi di inattività.

✔ Lista di controllo riassuntiva: scelta della linea di lavaggio per bottiglie in PET giusta

- Capacità: Allinearsi al volume di elaborazione previsto (ad esempio, 500–5000+ kg/h).

- Qualità di output: Garantire il rispetto degli standard di purezza (di qualità alimentare, se necessario).

- Efficienza di lavaggio: Cercate sistemi di pulizia completi e multifase.

- Automazione: Scegli l'automazione in base al budget e alle capacità della forza lavoro.

- Consumo di risorse: Optare per sistemi a basso consumo energetico e idrico, preferibilmente dotati di funzioni di riciclo.

- Flessibilità: Assicurarsi che la linea possa gestire materiali di input diversi.

- Requisiti di spazio: Verifica che il sistema si adatti alla tua struttura senza creare interruzioni.

- Costo totale di proprietà: Bilanciare costi di acquisto, efficienza, manutenzione e assistenza.

Valutando attentamente questi aspetti alla luce dei tuoi obiettivi aziendali, puoi investire in un Linea di lavaggio bottiglie PET che migliora efficienza produttiva, qualità del prodotto, E rapporto costo-efficacia, garantendo il successo immediato e a lungo termine.