Hard polypropyleen (PP) en polyethyleen met hoge dichtheid (HDPE) behoren tot de meest gerecyclede kunststoffen in industriële toepassingen. Ze worden vaak gewonnen uit gebruikte verpakkingen, spuitgietproducten, kratten, containers en productieafval.

Na het versnipperen en wassen worden deze materialen doorgaans verwerkt tot... plastic vlokken. Vlokken alleen zijn echter lastig op te slaan, te vervoeren en consistent te hergebruiken. Door middel van pelleteren worden onregelmatige vlokken omgezet in uniforme korrels, waardoor stabiele vervolgprocessen zoals spuitgieten, extrusie of compounding mogelijk worden.

Deze handleiding legt uit hoe stijve PP- en HDPE-vlokken worden gepelletiseerd, de technische uitdagingen die daarbij komen kijken, en hoe je een geschikte pelletiseeroplossing selecteert voor industriële recyclingprocessen.

Wat is het pelleteren van harde PP- en HDPE-vlokken?

Het pelletiseren van harde kunststofvlokken is een thermomechanisch proces waarbij gereinigde PP- of HDPE-vlokken worden gesmolten en opnieuw gevormd tot gestandaardiseerde pellets.

Vergeleken met direct hergebruik van vlokken biedt pelletiseren verschillende voordelen:

- Verbeterde bulkdichtheid voor eenvoudiger hanteren en opslaan.

- Constante toevoer naar de stroomafwaartse apparatuur

- Betere smelthomogeniteit en productstabiliteit

- Hogere marktwaarde voor gerecycled materiaal

Voor industriële recyclingbedrijven is het pelletiseren vaak een cruciale stap die bepaalt of gerecycled PP en HDPE opnieuw in hoogwaardige toepassingen kunnen worden gebruikt.

Stapsgewijs pelletiseerproces voor harde plastic vlokken

Hoewel de systeemconfiguraties kunnen variëren, volgen industriële pelletiseerlijnen over het algemeen dezelfde kernprocesstappen.

Toevoer en voorverdichting

Stijve plastic vlokken hebben doorgaans een lage en inconsistente bulkdichtheid. Een gecontroleerd toevoersysteem zorgt voor een stabiele materiaaltoevoer naar de extrusiefase.

Voorverdichting verbetert de invoerefficiëntie, vermindert het luchtgehalte en stabiliseert de doorvoer, wat essentieel is voor een continue bedrijfsvoering.

Plastificatie en smelthomogenisatie

Nadat de vlokken in de extruder zijn gebracht, worden ze verhit, samengeperst en gesmolten. Een goede plastificering is cruciaal voor hard PP en HDPE, omdat de materiaalhistorie, de mate van verontreiniging en de vlokgrootte aanzienlijk kunnen variëren.

Gelijkmatig smelten zorgt voor een constante smeltstroom en minimaliseert kwaliteitsfluctuaties in de uiteindelijke pellets.

Vacuüm ontgassen

Vocht, restanten van detergenten en vluchtige stoffen met een laag moleculair gewicht kunnen zelfs na het wassen in gerecyclede vlokken achterblijven.

Door vacuümontgassing worden deze ongewenste componenten uit het gesmolten plastic verwijderd, waardoor de oppervlaktekwaliteit, de mechanische eigenschappen en de geurbeheersing van de korrels verbeteren. Deze stap is met name belangrijk voor toepassingen die een stabiel verwerkingsgedrag vereisen.

Smeltfiltratie

Verontreinigingen zoals papiervezels, aluminiumfragmenten of achtergebleven etiketten kunnen de pelletkwaliteit en de daaropvolgende apparatuur negatief beïnvloeden.

Door middel van smeltfiltratie worden deze onzuiverheden uit het gesmolten plastic verwijderd, waardoor de gereedschappen worden beschermd en schonere, consistentere korrels worden gegarandeerd.

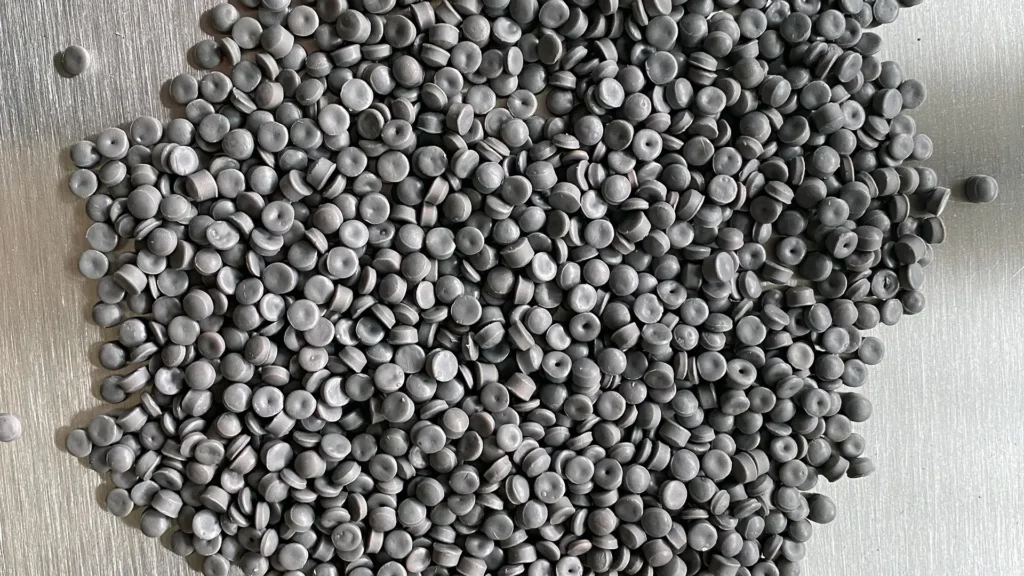

Pelletiseren en koelen

Het gezuiverde smeltproduct wordt vervolgens in korrels gesneden met behulp van een korrelvormingsmethode die geschikt is voor harde kunststoffen. Na de korrelvorming worden de korrels afgekoeld en gedroogd om veilige opslag en verwerking te garanderen.

Een uniforme korrelgrootte verbetert de doorstroming, de doseernauwkeurigheid en de verwerkingsstabiliteit in de daaropvolgende productiestappen.

Belangrijkste uitdagingen bij het pelletiseren van harde PP- en HDPE-vlokken

Het pelletiseren van harde kunststoffen brengt unieke uitdagingen met zich mee die op systeemontwerpniveau moeten worden aangepakt:

- Variabele vlokgeometrie van verschillende versnipperingsprocessen

- Inconsistent vochtgehalte na het wassen

- Restverontreiniging beïnvloedt de smeltkwaliteit

- Risico's op materiaaldegradatie door overmatige hitte of schuifkracht

Het is essentieel om deze uitdagingen te begrijpen bij de evaluatie van pelletiseeroplossingen voor langdurig industrieel gebruik.

Eentraps versus tweetraps pelletiseersystemen

Stijve PP- en HDPE-vlokken kunnen met verschillende systeemconfiguraties tot pellets worden verwerkt. De meest voorkomende methoden zijn pelletiseren in één of twee stappen.

Eentrapssystemen

- Eenvoudigere lay-out

- Lagere initiële investering

- Geschikt voor schone, goed voorbereide vlokken.

Tweetrapssystemen

- Verbeterde ontgassingsprestaties

- Verbeterde smeltstabiliteit

- Betere verwerking van variabel of verontreinigd invoermateriaal.

De optimale keuze hangt af van de materiaalkwaliteit, de kwaliteitsdoelstellingen en de productievereisten.

Hoe kies je het juiste pelletiseersysteem voor harde kunststoffen?

Bij de evaluatie van pelletiseeroplossingen moeten industriële recyclers rekening houden met de volgende factoren:

- Kwaliteit van het inputmateriaal (reinheid, vochtigheid, consistentie)

- Doelgerichte pellettoepassing (spuitgieten, extrusie, compounding)

- Vereiste stabiliteit van de output en pelletuniformiteit

- Operationele betrouwbaarheid voor continue productie

- Toekomstige schaalbaarheid en integratie met was- of menglijnen

Een systeem dat is afgestemd op de werkelijke productieomstandigheden levert een hogere efficiëntie, minder stilstand en een voorspelbaardere pelletkwaliteit op.

Industriële pelletiseerapparatuur voor hard PP en HDPE.

Voor recycling op industriële schaal zijn speciaal ontworpen pelletiseermachines nodig om harde PP- en HDPE-vlokken efficiënt te verwerken en tegelijkertijd een constante pelletkwaliteit te garanderen.

👉 Aanbevolen oplossing:

Machine voor het pelleteren van harde PP- en HDPE-kunststofvlokken

Deze apparatuur is speciaal ontworpen voor de recycling van hard plastic en combineert stabiele aanvoer, effectieve ontgassing en betrouwbare pelletering in één industriële oplossing.

Laatste gedachten

Het pelletiseren van harde PP- en HDPE-vlokken is een cruciale stap in de transformatie van gerecyclede kunststoffen naar bruikbare industriële grondstoffen. Een goed begrip van het proces, de uitdagingen en de selectiecriteria voor het systeem stelt recyclers in staat weloverwogen beslissingen te nemen en consistente productieresultaten te behalen.

Door te scheiden proceskennis van selectie van apparatuur, Hierdoor kunnen recyclingbedrijven oplossingen beter evalueren en efficiënte, schaalbare recyclingprocessen opzetten.