Ontgrendel efficiëntie in plastic recycling

Maak kennis met de Vertical Debaler Machine: de geautomatiseerde oplossing om moeiteloos samengeperste plastic balen af te breken en uw recyclinglijn een boost te geven.

Waarom zou u voor onze verticale ontbalingsmachine kiezen?

⚡

Ongeëvenaarde efficiëntie

Automatiseert het ontbalingsproces, waardoor de handmatige arbeid en voorbereidingstijd drastisch worden verminderd.

📈

Verhoogde doorvoer

Verwerkt meerdere balen tegelijkertijd voor continue verwerking van grote volumes.

💲

Aanzienlijke kostenbesparingen

Minimaliseert operationele kosten door de arbeidsbehoefte te verlagen en uw workflow te stroomlijnen.

Van baal tot fles in 4 eenvoudige stappen

Balen laden

Plaats maximaal vijf balen op de invoerband met behulp van een vorkheftruck.

Banden knippen

Knip snel en veilig de draden of banden door waarmee elke baal vastzit.

Geautomatiseerd ontbalen

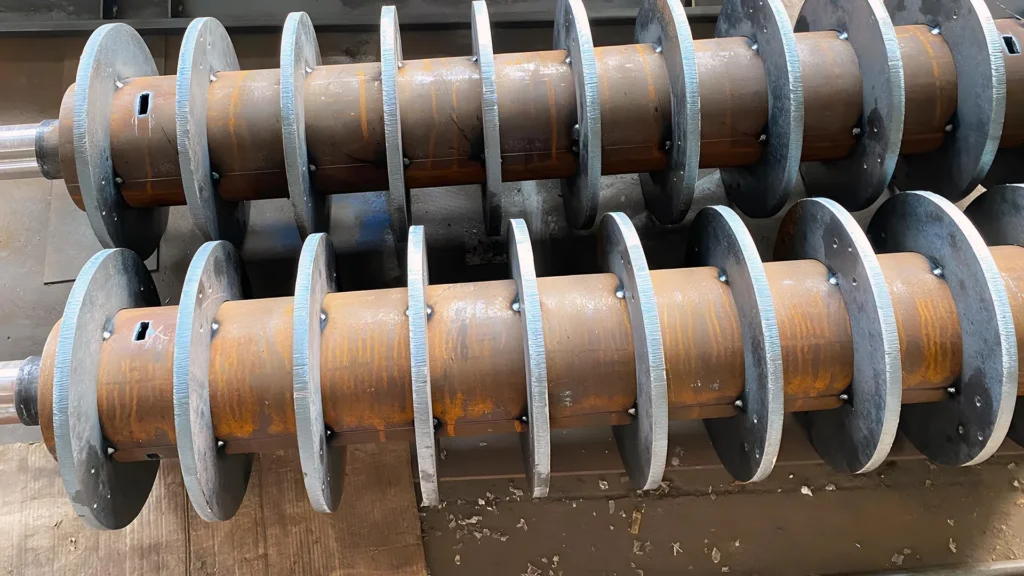

Dubbele, tegengesteld draaiende rotoren breken verdichte kunststoffen nauwkeurig uiteen.

Continue output

Losgemaakte materialen stromen naar de volgende transportband, klaar voor recycling.

Ontworpen voor prestaties

Dubbele tegengesteld draaiende rotoren

Het hart van de machine, ontworpen voor maximale breekkracht en efficiëntie.

Technische specificaties

| Functie | Specificatie |

| Hoofdmotorvermogen | 7,5 kW x 2 (Totaal 15 kW) |

| Voederafmeting | 1550 mm x 1850 mm |

| Toepasselijke materialen | Gecompacteerde HDPE-, PET-flessen en andere stijve kunststoffen |

| Certificering | CE-gecertificeerd |

| Aanpassing | Hogere vermogens en grotere modellen op aanvraag leverbaar |

Veelzijdige toepassingen en hoogwaardige output

Ontvang een oplossing op maat en een offerte

Klaar om uw recyclingactiviteiten te revolutioneren? Vul onderstaand formulier in en onze experts nemen contact met u op om uw specifieke behoeften te bespreken.

Veelgestelde vragen

Wat is de primaire functie van de verticale ontbalingsmachine?

De belangrijkste functie is het automatisch uiteenrafelen van samengeperste balen van hard plastic, zoals PET- en HDPE-flessen, ter voorbereiding op de volgende fase van het recyclingproces, zoals sorteren, wassen of versnipperen.

Kan deze machine balen plasticfolie verwerken?

Nee, deze machine is speciaal ontworpen voor harde kunststoffen. Plastic folie kan zich om de rotoren wikkelen en schade veroorzaken. Voor balen plastic folie adviseren wij een speciale folieversnipperaar of balenbreker.

Wat is de doorvoercapaciteit?

De doorvoer is afhankelijk van het model en de dichtheid van de balen. Ons standaardmodel kan meerdere tonnen per uur verwerken. We kunnen exacte cijfers geven op basis van uw specifieke materiaal en baalgrootte.

Hoeveel handarbeid is er nodig?

Handarbeid is minimaal. Er is een operator nodig om de balen met een heftruck te laden en de baaldraden/-banden door te knippen voordat ze de machine ingaan. Het ontbalingsproces zelf is volledig geautomatiseerd.