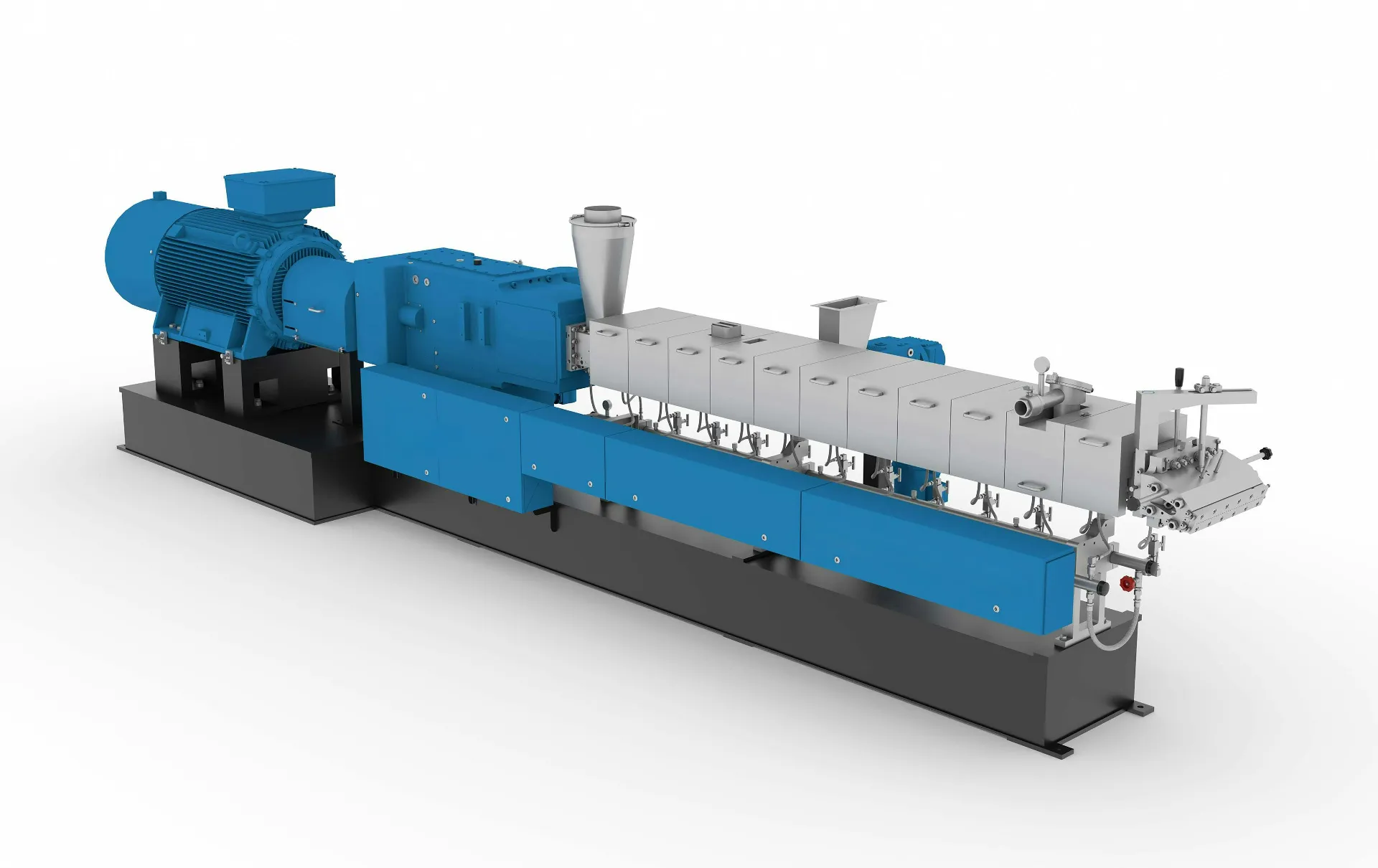

Twin-Screw Extruder System

A reliable, modular co-rotating twin-screw platform for stable melting, conveying, and continuous extrusion—ideal for profiles, pipe, sheet, and general polymer processing.

Request a QuoteStable Output for Daily Production

This is a general-purpose twin-screw extruder system focused on dependable extrusion performance and easy maintenance. For intensive mixing, devolatilization, filtration, and pelletizing (a full compounding line), choose a dedicated compounding pelletizing line instead.

Key Features

Modular “Building-Block” Design

Flexible screw elements and modular barrels adapt the extruder to your material and product requirements.

Gearbox Options

Multiple torque series (standard to high-torque) with optional safety coupling for stable long-term operation.

Self-Cleaning Screws

Full-mesh screw design reduces residue and helps prevent localized overheating during continuous extrusion.

Accurate Temperature Control

Independent heating zones help maintain stable melt viscosity and consistent product dimensions.

Feeding & Metering Support

Compatible with volumetric and loss-in-weight feeders, plus main/side feeding configurations.

Maintenance Friendly

Replaceable alloy inserts and functional barrel sections simplify service and reduce downtime.

How It Works

- Feeding: Pellets/powders are fed via main hopper; side feeding is available when needed.

- Melting & Plastification: The twin screws heat and melt material with stable temperature zoning.

- Mixing & Conveying: Material is conveyed to the die while maintaining a consistent melt flow.

- Venting (Optional): Remove moisture and volatiles for cleaner extrusion and fewer surface defects.

- Die Forming: The melt is shaped through a die into profile/pipe/sheet or other products.

- Downstream Handling: Calibration/cooling, hauling, and cutting are integrated per your product line.

Typical Applications

Profiles & WPC

PVC and WPC profiles for building materials and industrial components.

Pipe Extrusion

Stable melt delivery for PVC/PE pipe systems with downstream calibration and haul-off.

Sheet & Board

Sheet/board extrusion lines requiring consistent thickness control.

Cable Compounds (Extrusion)

Extrusion support for cable materials with appropriate feeding and temperature zoning.

Technical Specifications

| Specification | Value |

|---|---|

| Screw Diameter | 50–150 mm |

| L/D Ratio | Up to 68:1 |

| Max. Screw Speed | Up to 600 rpm |

| Motor Power | 55–450 kW |

| Max. Capacity | 150–2000 kg/h |

*Final specs depend on material, die, and downstream configuration.

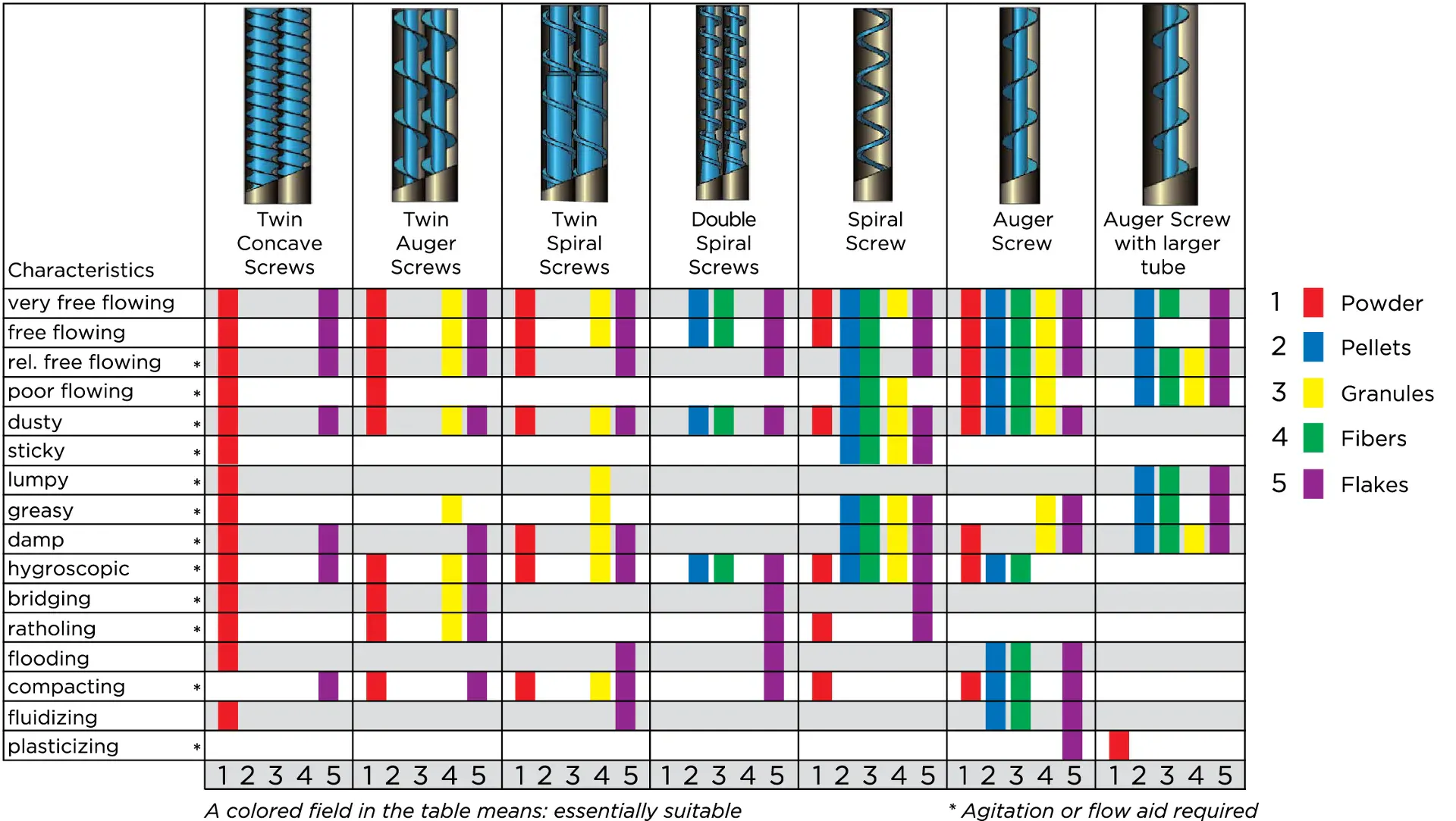

Various Screw Configurations

See the Extruder System

A short walkthrough of the twin-screw extruder platform and its modular configuration.

Warranty & Installation

1-Year Limited Warranty

All of our extruder systems include a comprehensive one-year limited warranty.

Commissioning Support

We provide installation guidance, parameter setup suggestions, and after-sales support for stable production.

Frequently Asked Questions

What materials can this twin-screw extruder system process?

It is commonly used for PVC and other thermoplastics depending on configuration. Share your polymer, additives, and target product (profile/pipe/sheet) for a recommended setup.

How do I select screw diameter and L/D ratio?

Selection depends on your target output, melt stability needs, die type, and product dimensions. We size the system based on your throughput and application requirements.

Do you offer venting or vacuum options?

Yes. Venting and vacuum can be configured to remove moisture and volatiles, improving surface quality and reducing bubbles.

Can the system be customized with downstream equipment?

Yes. We can match dies, calibration/cooling tanks, haul-off, and cutting systems to build a complete extrusion line for your product.

When should I choose a dedicated compounding pelletizing line instead?

If your main goal is intensive mixing/compounding with filtration and pelletizing into uniform pellets (e.g., masterbatch or filled compounds), a dedicated compounding pelletizing line is more suitable.

Request a Configuration Proposal

Share your material, target product (profile/pipe/sheet), and capacity. We’ll recommend screw diameter, L/D, gearbox, venting, and downstream equipment.