Technical Guide · Blade Material Selection

SKD-11 vs D2 vs DC53 vs 55SiCr: Best Blade Steel for Plastic Shredders

Blade material selection directly affects cutting efficiency, service life, energy consumption, and downtime in plastic recycling. This guide compares four widely used blade steels—SKD-11 (D2 equivalent), D2, DC53, and 55SiCr—so you can match the right material to your plastic type, contamination level, and operating conditions.

Why Blade Material Matters

In plastic shredders and crushers, blades face continuous abrasion, impact loads, heat buildup, and occasional metal contamination. Choosing the wrong steel grade typically shows up as fast edge wear, chipping, frequent sharpening, unstable particle size, and rising power draw. Choosing the right grade improves uptime and lowers the total cost per ton processed.

Rule of thumb: Abrasion-heavy plastics favor wear resistance. Impact-heavy or contaminated streams demand higher toughness.

Quick Recommendations

Best for abrasive materials

D2 / SKD-11 for long wear life in rigid plastics and abrasive streams (e.g., filled plastics, dirty regrind).

Best balance (wear + toughness)

DC53 when you need both wear resistance and impact toughness (mixed plastics, PVC, rubbery/variable feed).

Best for shock/impact loads

55SiCr for conditions with sudden impacts, vibration, or frequent hard inclusions—often used where toughness is priority.

Best starting point

If you’re unsure, start with DC53 for mixed streams, then optimize after wear data and sharpening intervals.

Final performance also depends on blade geometry, heat treatment, clearance, rotor speed, and whether your machine is a shredder or crusher. A strong steel grade cannot compensate for the wrong cutting setup.

Material Comparison Table

| Steel grade | Wear resistance | Toughness | Best use cases | Typical plastics |

|---|---|---|---|---|

| SKD-11 (D2 family) | Very high | Medium | Long runtime, stable cutting edge | ABS, PS, PA/nylon, rigid regrind |

| D2 | Very high | Medium | Abrasive/dirty materials, filled plastics | GF-filled plastics, mixed rigid, tough regrind |

| DC53 | High | High | Best balance for variable feedstock | PVC, mixed plastics, rubber, inconsistent streams |

| 55SiCr | Medium | Very high | Impact-heavy conditions, shock loads | Softer plastics, contaminated streams with impacts |

Note: “Best” depends on your waste stream. A blade that lasts longest on clean rigid plastics may chip on impact-heavy mixed waste.

Material Profiles

SKD-11 (often compared to D2)

- Strength: excellent wear resistance and stable edge retention.

- Best for: long campaigns on rigid plastics with consistent feed.

- Watch-outs: can chip if feedstock contains frequent hard impacts or metal inclusions.

D2

- Strength: very high wear resistance, especially in abrasive conditions.

- Best for: abrasive/dirty materials and filled plastics (e.g., glass-fiber content).

- Watch-outs: medium toughness; prioritize proper clearance and contamination control.

DC53

- Strength: strong balance of wear resistance and toughness.

- Best for: mixed plastics, PVC, and variable feedstock where impacts happen.

- Watch-outs: performance depends heavily on heat treatment and stable operating setup.

55SiCr

- Strength: high shock absorption and toughness under impact.

- Best for: applications where chipping is the main failure mode.

- Watch-outs: typically lower wear resistance; may require more frequent sharpening in abrasive streams.

How to Choose the Right Blade

1) Plastic type & hardness

Rigid plastics and engineering polymers often favor wear resistance. Softer plastics may tolerate lower hardness but need stability against impacts.

2) Abrasives & contamination

Glass fiber, mineral fillers, sand/dirt, and dirty streams quickly wear edges—prioritize D2/SKD-11 or DC53 depending on impacts.

3) Impact loads

Hard inclusions and inconsistent feed can chip blades—prioritize toughness (DC53 or 55SiCr) and tighten contamination control.

4) Output size & throughput

High throughput increases heat and load. Ensure the steel grade matches your duty cycle and maintenance intervals.

Practical approach: If you process mixed plastics, choose DC53 first. If you process abrasive filled plastics, choose D2/SKD-11. If chipping dominates, consider 55SiCr.

Tips to Extend Blade Life

- Control contamination: remove metal and stones upstream whenever possible.

- Maintain clearance: incorrect knife gap accelerates wear and increases power draw.

- Use proper sharpening intervals: avoid running blades fully blunt—this increases heat and deformation risk.

- Match rotor speed to material: too fast increases heat; too slow can increase impact stress.

- Record wear data: track tonnage between sharpening to select the best grade for your stream.

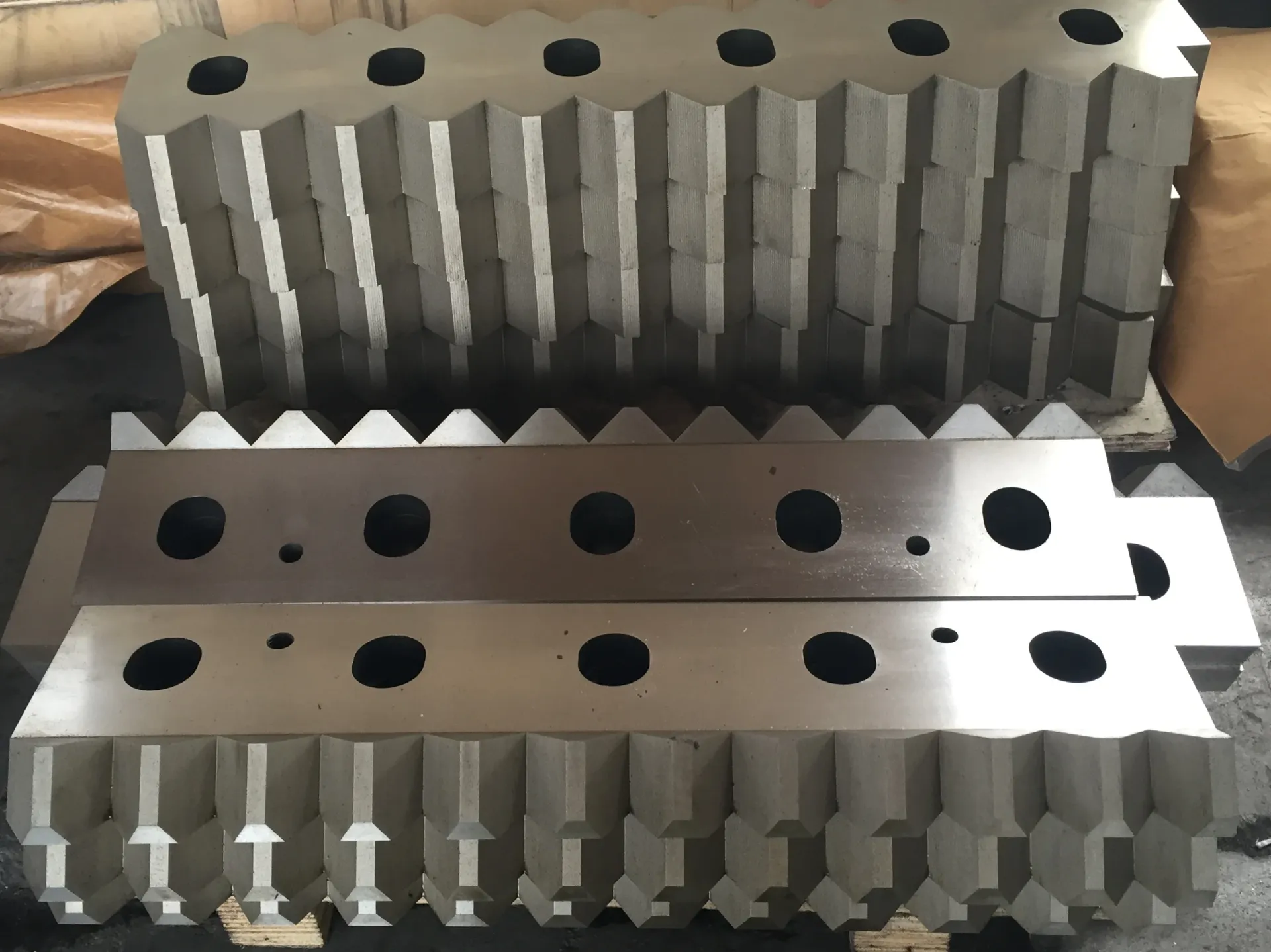

Which Shredders Use These Blades?

These blade materials are commonly used in single-shaft shredders, double-shaft shredders, and plastic crushers handling rigid plastics, films, woven bags, pipes, and mixed waste streams. The best grade depends on your application and machine design.

Explore plastic shredder models and applications here: Plastic Shredders.

FAQ

Is SKD-11 the same as D2?

They are closely related tool steels often compared in industry. Performance depends on heat treatment, hardness targets, and cutting geometry.

Which blade steel is best for PVC?

DC53 is commonly chosen for PVC and mixed streams because it balances wear resistance and toughness under variable conditions.

Why do blades chip even with “hard” steel?

Chipping is usually a toughness/impact issue: hard inclusions, metal contamination, incorrect clearance, or excessive impact loads.

Talk to an Engineer

Blade performance depends on plastic type, contamination, throughput, and machine configuration. If you share your material photos, target output size, and shredder or crusher model, the Energycle team can recommend the most suitable blade steel and a maintenance interval to protect uptime.

To recommend the right blade grade, please include:

- Plastic type and photos (clean vs dirty, fillers, labels, metal risk)

- Target capacity (kg/h) and operating hours/day

- Machine type (single-shaft, double-shaft, crusher) and model

- Target output size and screen (if applicable)