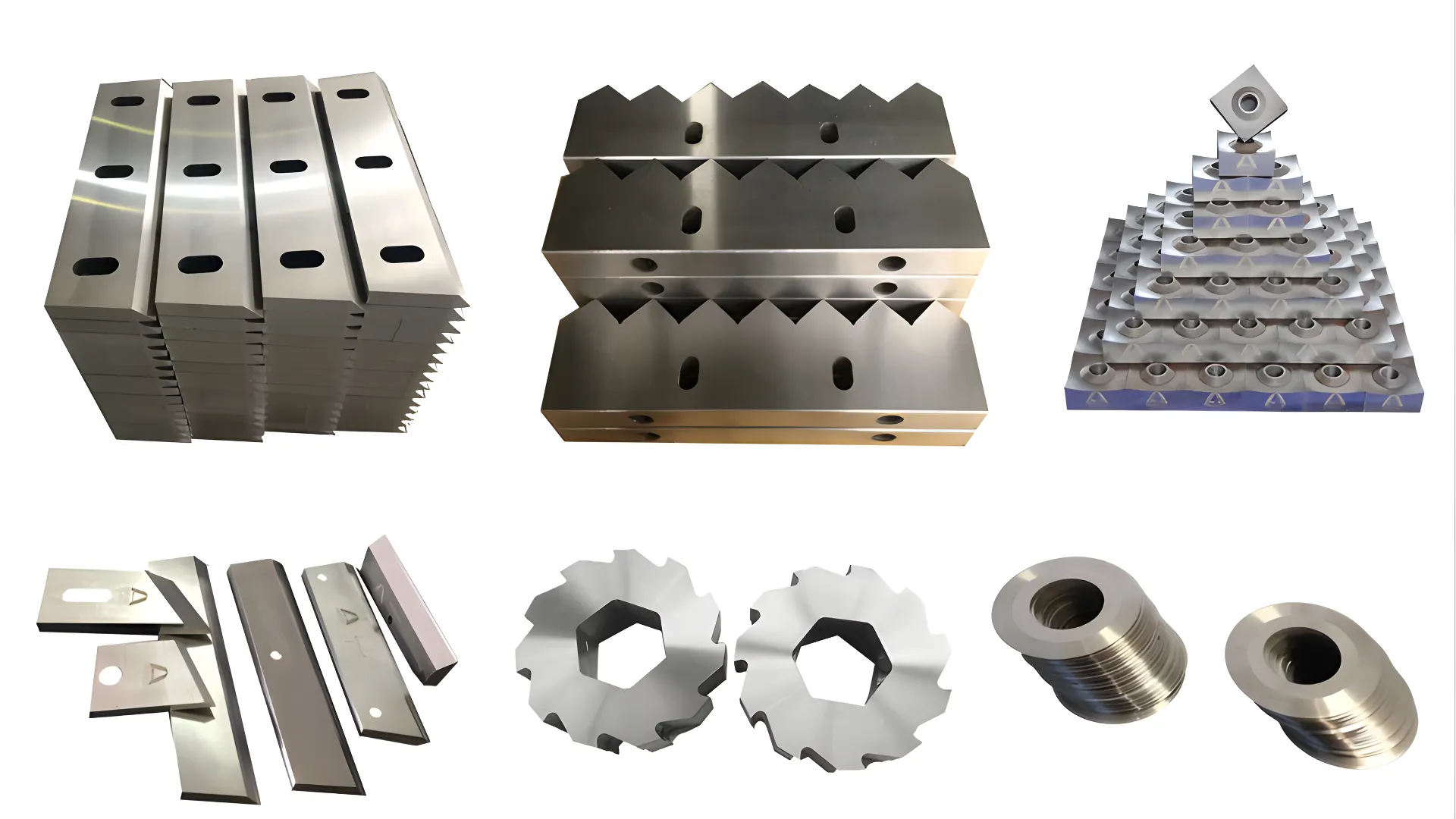

Versnipperaar messen are the most critical wear components in industrial shredders. Their material quality, heat treatment, geometry, and application matching directly determine shredding efficiency, energy consumption, downtime frequency, and overall operating cost.

For recycling plant owners, equipment buyers, and engineers, understanding how shredder blades are designed, manufactured, and selected is essential to maximizing return on investment and ensuring stable long-term operation.

Deze handleiding legt uit how shredder blades work, how they are made, which materials perform best for different applications, and how to choose the right blade for your shredding task.

Why Shredder Blades Matter in Industrial Recycling

In a typical industrial shredder, blades account for approximately 15–25% of the machine’s total cost, yet they have a disproportionate impact on performance and maintenance expenses.

Poor blade selection can lead to:

- Excessive wear or frequent blade replacement

- Increased power consumption

- Inconsistent particle size

- Shaft overload, vibration, or bearing damage

By contrast, properly selected blades:

- Deliver consistent output size

- Reduce energy use per ton processed

- Extend service intervals

- Protect the shredder’s drivetrain and structure

In plastic recycling operations—where materials vary widely in hardness, contamination, and shape—blade choice is especially critical.

Core Functions of Shredder Blades

Industrial shredder blades perform three primary functions:

- Material Gripping

Blade hook profiles capture bulky or flexible materials (films, woven bags, pipes) and prevent slippage. - Shearing and Tearing

Counter-rotating blades generate shear forces that fracture plastics, rubber, or composites along controlled stress lines. - Size Reduction Control

Blade thickness, spacing, and quantity determine final particle size and throughput balance.

Effective blade design is always a compromise between cutting aggressiveness, durability, and shock resistance.

Shredder Blade Manufacturing Process (Industrial Standard)

High-quality shredder blades must follow strict manufacturing and quality-control procedures. A professional process typically includes:

1. Raw Material Selection

Premium alloy tool steels such as Cr12MoV, D2, DC53, or SKD11 are chosen for their wear resistance, toughness, and heat-treatment stability.

2. Precision Cutting

Laser or water-jet cutting ensures dimensional accuracy, smooth edges, and minimal internal stress.

3. Forging (When Required)

Forging improves internal grain structure and mechanical strength for heavy-duty applications.

4. Rough Machining

CNC machining removes excess material and prepares the blade for heat treatment.

5. Heat Treatment

Vacuum or controlled-atmosphere heat treatment optimizes hardness, toughness, and microstructure consistency.

6. Tempering

Multiple tempering cycles balance hardness with impact resistance, reducing brittleness.

7. Finish Grinding and Wire Cutting

Final grinding ensures flatness, precise tooth geometry, and consistent hardness across the blade surface.

Each step directly affects blade lifespan and real-world shredding performance.

Common Shredder Blade Materials Explained

Different shredding applications demand different blade steels. Below is a practical comparison used by industrial buyers:

Cr12MoV

- Hardheid: Hoog

- Slijtvastheid: Uitstekend

- Het beste voor: General plastic recycling, rigid plastics, mixed industrial waste

- Kracht: Cost-effective and widely used

D2 Tool Steel

- Hardheid: Zeer hoog

- Slijtvastheid: Uitstekend

- Het beste voor: Abrasive plastics, contaminated materials

- Opmerking: Less impact-resistant than Cr12MoV

DC53

- Hardheid: Hoog

- Taaiheid: Superior to D2

- Het beste voor: High-load shredding with impact risk

- Voordeel: Reduced chipping and longer service life

SKD11

- Hardheid: Stable

- Slijtvastheid: Uitstekend

- Het beste voor: Precision shredding and long production runs

- Kracht: Consistent quality when properly heat treated

Important insight:

Higher hardness does not always mean better performance. For impact-heavy materials, excessive hardness can cause blade chipping or cracking.

Matching Blade Design to Application

Selecting shredder blades is not only about material—it is about application matching.

Kunststofrecycling

- Medium hook depth

- Balanced hardness and toughness

- Optimized for PET, HDPE, PP, film, and injection scrap

Film, Big Bags, and Woven Materials

- Aggressive hook profile

- Higher toughness to prevent edge breakage

- Proper shaft speed coordination

Tires and Rubber

- Thick blades with reinforced geometry

- Emphasis on impact resistance

- Often paired with hardened spacers

Mixed or Contaminated Waste

- Wear-resistant steel

- Conservative hardness settings

- Designed to tolerate metal traces and dirt

Correct matching significantly extends blade life and stabilizes throughput.

Blade Thickness, Quantity, and Output Size

Blade configuration directly affects output characteristics:

- Thicker blades:

- Higher torque capacity

- Coarser output

- Longer lifespan

- Thinner blades:

- Finer output

- Higher cutting efficiency

- Faster wear in abrasive conditions

Blade quantity and spacer arrangement define final particle size and should be coordinated with downstream equipment such as granulators or washing lines.

Maintenance and Blade Life Optimization

Even premium blades require proper maintenance to reach their full service life:

- Rotate or re-grind blades before severe edge rounding

- Avoid over-feeding and shock loading

- Monitor shaft alignment and bearing condition

- Match screen size and discharge settings to blade design

Preventive maintenance costs far less than emergency downtime.

Conclusie

Shredder blades are the core working elements of any industrial shredder. Their material selection, manufacturing quality, geometry, and application matching directly determine productivity, operating cost, and machine longevity.

For recycling professionals and equipment buyers, investing time in proper blade selection is not optional—it is a strategic decision that impacts the entire recycling line.

If you require application-specific blade recommendations, custom blade design, or replacement blades for plastic shredders, Energycle-machine provides engineered solutions tailored to real-world recycling demands.