Invoering

Het kiezen van het juiste pelletiseersysteem voor uw PET-productielijn is een cruciale beslissing die een aanzienlijke impact kan hebben op uw operationele efficiëntie, productkwaliteit en kosten op de lange termijn. Tot de meest gebruikte methoden behoren: waterringpelletisering En watergekoelde strengpelletiseringElk systeem heeft zijn voordelen en is geschikt voor verschillende productiedoelen en faciliteitsbeperkingen.

Bij Energycle-machineWij zijn gespecialiseerd in het helpen van fabrikanten in de VS en Europa bij het optimaliseren van hun recycling- en polymeerverwerkingslijnen. Als u systemen voor PET-vlokken overweegt, bezoek dan onze PET-kunststofvlokken enkelschroefpelletiseerder pagina voor meer informatie over hoogefficiënte enkelvoudige schroefoplossingen.

Deze uitgebreide gids begeleidt u door een evenwichtige vergelijking van beide pelletiseringstechnologieën, zodat u de technologie kunt vinden die het beste bij uw specifieke behoeften past.

De basisprincipes van PET-pelletisering begrijpen

Het pelletiseren van PET (polyethyleentereftalaat) is een vervolgproces in de productielijn voor kunststofrecycling of nieuwe polymeren, waarbij gesmolten PET wordt omgezet in vaste pellets. Deze pellets zijn gemakkelijker te verwerken, te transporteren en te hergebruiken in productieprocessen.

De twee dominante systemen zijn:

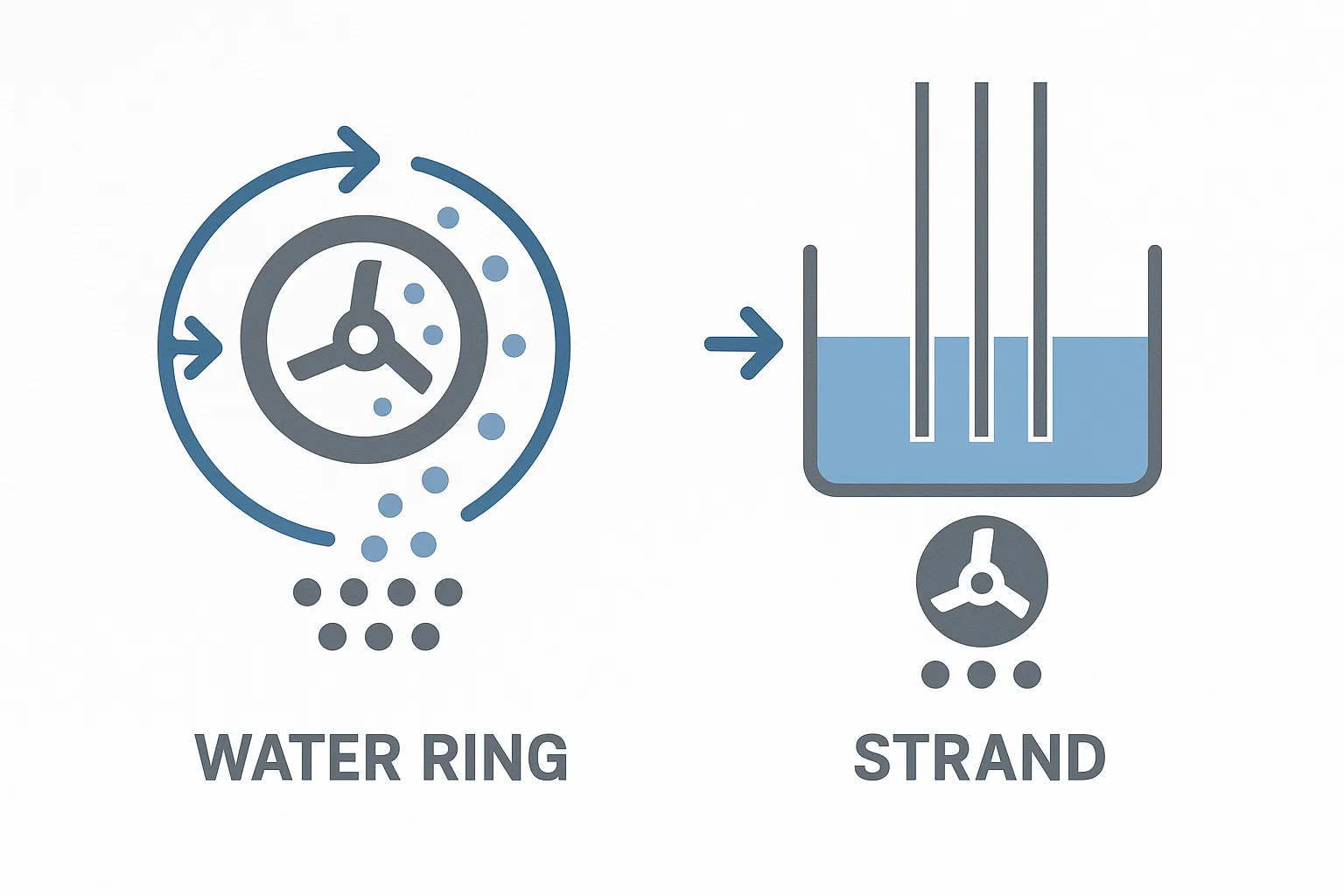

- WaterringpelletiserenGesmolten PET wordt door een matrijs geëxtrudeerd en direct door roterende messen in pellets gesneden. De pellets worden vervolgens gekoeld in een circulerende waterring.

- Watergekoelde strengpelletiseringGesmolten PET wordt geëxtrudeerd als doorlopende strengen, afgekoeld in een waterbad en vervolgens in pellets gesneden.

Voor PET-flessenvlokken, Energycle-machine biedt ook gespecialiseerde pelletiseersystemen Ontworpen voor een stabiele output en consistente pelletkwaliteit.

Voetafdruk en ruimtevereisten

Waterringpelletiseren

Waterringsystemen zijn compact en sterk geïntegreerd. Ze nemen minder vloeroppervlak in beslag, waardoor ze ideaal zijn voor ruimtes waar ruimte schaars is. Alle belangrijke componenten, waaronder de snijkop, waterring en droger, worden doorgaans als één geheel gemonteerd.

Watergekoelde strengpelletisering

Strandsystemen vereisen meer vloeroppervlak vanwege de koelwaterbakken en de strandindeling. Deze opstelling kan beperkingen opleveren voor kleinere fabrieken of retrofit-installaties. Het biedt echter mogelijk meer flexibiliteit bij het verwerken van verschillende materiaalviscositeiten.

Energycle-machine adviseert om de lay-out van uw fabriek te beoordelen om te bepalen welk systeem het beste past bij uw operationele footprint.

Automatisering en gebruiksvriendelijkheid

Waterringpelletiseren

Waterringsystemen zijn over het algemeen meer geautomatiseerd en vereisen minder tussenkomst van de operator. De druk van de messen is vaak zelfregelend en het drogen van pellets is geïntegreerd, waardoor handmatige handelingen minder nodig zijn.

Watergekoelde strengpelletisering

Strengelpelletiseersystemen zijn arbeidsintensiever. Operators moeten zorgen voor een correcte uitlijning van de strengen en een constante waterstroom. Het opstarten en uitschakelen vereist meer aandacht en vaardigheid.

Voor fabrikanten die de arbeidskosten willen verlagen en de consistentie willen verbeteren, Energycle-machine stelt voor om waterringpelletisering te overwegen vanwege de automatiseringsvoordelen ervan.

Pelletvorm en kwaliteit

Waterringpelletiseren

Produceert ronde, uniforme pellets met een glanzende afwerking. Deze zijn vooral geschikt voor hoogwaardige toepassingen waarbij de esthetiek en vloeibaarheid van de pellets van belang zijn.

Watergekoelde strengpelletisering

Pellets zijn meestal cilindrisch met licht onregelmatige uiteinden. Hoewel ze nog steeds geschikt zijn voor de meeste toepassingen, voldoen ze mogelijk niet aan de hoogste esthetische of verwerkingsnormen.

Als de uniformiteit en het uiterlijk van de pellets van cruciaal belang zijn voor uw toepassing, Energycle-machine adviseert waterringsystemen.

Samenvattende vergelijkingstabel

| Functie | Waterringpelletiseren | Watergekoelde strengpelletisering |

|---|---|---|

| Voetafdruk | Compact | Grotere ruimte nodig |

| Automatisering | Hoog | Gemiddeld tot laag |

| Pelletvorm | Rond, uniform | Cilindrisch, variabel |

| Onderhoud | Gematigd | Lager slijtagerisico |

| Initiële kosten | Hoger | Lager |

| Bedrijfskosten | Lagere langetermijn | Hogere arbeidskosten |

| Doorvoer | Hoog | Medium |

| Materiaalflexibiliteit | Medium | Hoog |

Veelgestelde vragen

V1: Kan ik een waterringpelletiseerder achteraf inbouwen in mijn bestaande PET-lijn?

Ja, veel van Energycle-machineDe modellen van zijn ontworpen voor retrofit, maar lay-out- en extrusieparameters moeten worden geëvalueerd.

Vraag 2: Welke pelletiseermachine is het meest geschikt voor gerecycled PET?

Waterringpelletisering is vaak beter voor gerecycled PET vanwege de hogere doorvoer en betere integratie van het drogen.

V3: Zijn er hybride systemen beschikbaar?

Sommige systemen bieden modulaire opties die de kenmerken van beide pelletiseertypen combineren. Energycle-machine kan u adviseren over oplossingen op maat.

Vraag 4: Wat is de typische terugverdientijd voor het upgraden naar een waterringsysteem?

Afhankelijk van uw output en arbeidskosten kan de terugverdientijd variëren van 1 tot 3 jaar.

Maak de juiste keuze voor uw productielijn

De keuze voor het juiste pelletiseersysteem kan de toekomst van uw PET-productielijn bepalen. Energycle-machine u helpen een weloverwogen, toekomstbestendige investering te doen.

Bezoek onze PET-kunststofvlokken enkelschroefpelletiseerder pagina of neem vandaag nog contact met ons op om uw wensen te bespreken.

Vraag een offerte op maat aan