Geavanceerde schroeftransportoplossingen voor moderne industrieën

Verbeter uw materiaalverwerkingscapaciteiten met onze nauwkeurig ontworpen schroeftransporteurs. Ontworpen voor ongeëvenaarde stabiliteit en duurzaamheid, bieden wij modellen met één, twee, drie en gespecialiseerde waterfiltratie, aanpasbaar aan uw specifieke operationele eisen.

Vraag een offerte aanOntgrendel efficiëntie en betrouwbaarheid

Ongeëvenaarde veelzijdigheid

Verwerkt vakkundig uiteenlopende materialen, van fijne poeders en korrels tot plakkerige of draderige stoffen, in een groot aantal industriële toepassingen.

Geoptimaliseerde efficiëntie

Ontworpen voor continu materiaaltransport over wisselende afstanden met minimaal energieverbruik, waardoor uw operationele output wordt gemaximaliseerd.

Minder onderhoud

Robuuste constructie met slijtvaste spiralen en minder bewegende onderdelen resulteert in lagere onderhoudskosten en een langere levensduur.

Op maat gemaakte oplossingen

Volledig aanpasbare ontwerpen, inclusief schroefdiameter, spoed en materiaal, om te voldoen aan specifieke transportbehoeften en ruimtebeperkingen.

De mechanica van materiële beweging

Het hart van elke schroeftransporteur is een zorgvuldig ontworpen spiraalvormige schroefblad (boor)Deze boor draait in een robuuste trog of buis.

Terwijl de schroef draait, stuwt hij het materiaal methodisch langs de transportband. Deze actie vergemakkelijkt een continue en gecontroleerde stroming van goederen vanaf het innamepunt tot aan het lospunt.

De ontwerpparameters van het schroefblad (grootte, vorm en spoed) worden nauwkeurig gekalibreerd op basis van de materiaaleigenschappen en toepassingsvereisten, waardoor een optimale transportefficiëntie wordt gegarandeerd.

Diverse transportbandontwerpen voor specifieke behoeften

Onze schroeftransporteurs zijn in verschillende configuraties ontworpen om te voldoen aan uiteenlopende operationele vereisten. Zo garanderen we optimale prestaties, ongeacht de uitdaging.

Horizontale schroeftransporteurs

Ideaal voor het efficiënt verplaatsen van bulkmaterialen, horizontaal of onder lichte hellingen. De werkpaard voor standaard transfertoepassingen.

Verticale schroeftransporteurs

Speciaal ontworpen voor het omhoog brengen van materialen van lagere naar hogere punten, perfect voor verwerkingsfaciliteiten met meerdere niveaus.

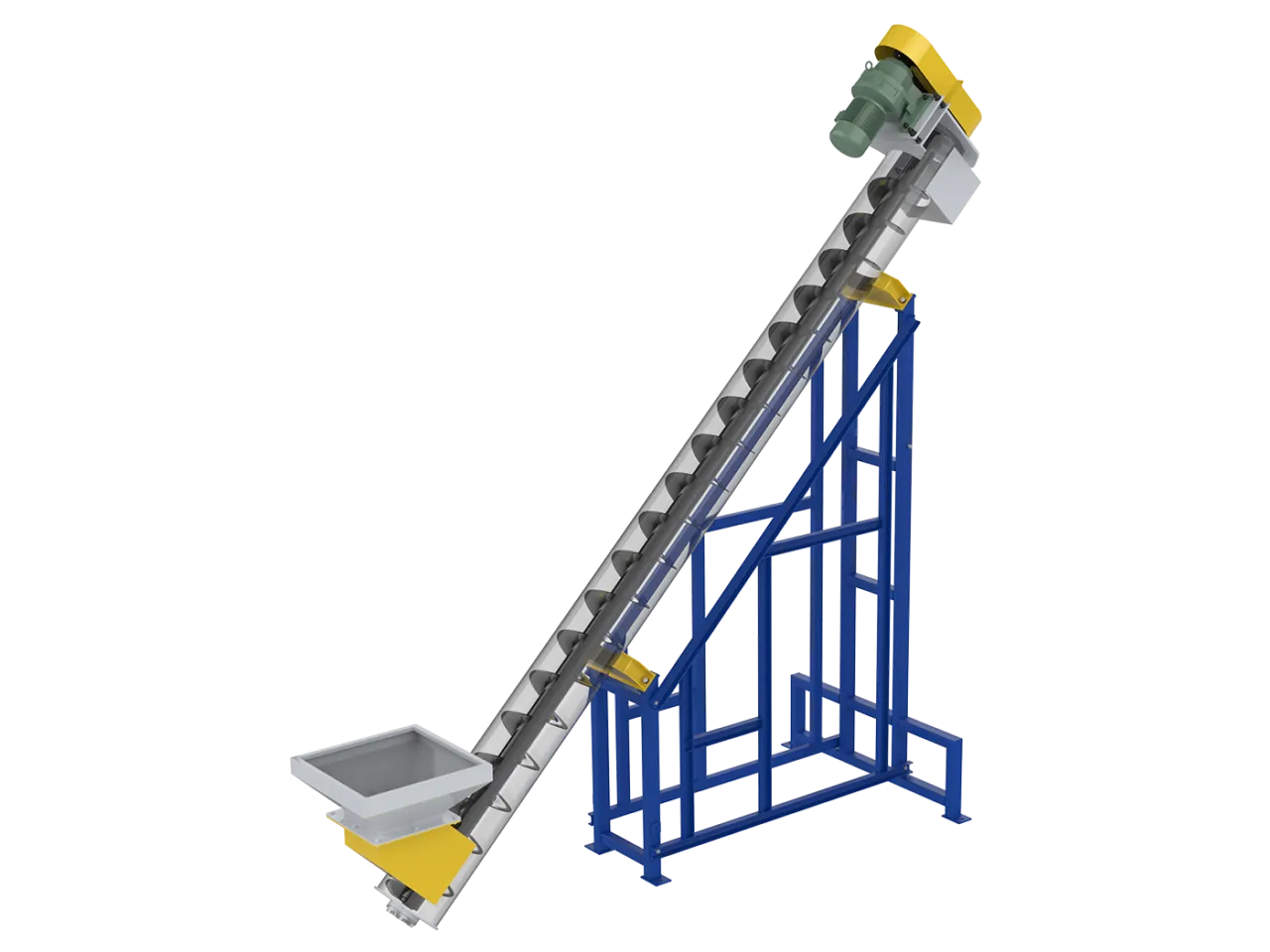

Schuine schroeftransporteurs

Wordt gebruikt voor het transporteren van materialen onder een hoek, doorgaans van een trechter naar verwerkingsmachines of opslagbakken.

Asloze schroeftransporteurs

De optimale oplossing voor het verwerken van lastige materialen, zoals plakkerige, draderige of volumineuze voorwerpen. Hiermee wordt verstrengeling, die vaak voorkomt bij ontwerpen met schachten, voorkomen.

Alle modellen beschikken over een hoge stabiliteit en slijtvaste spiralen. Er zijn aanpassingsmogelijkheden beschikbaar voor de schroefdiameter (van compact tot groot) en de materiaalkeuze om precies aan uw transportvereisten en ruimtelijke beperkingen te voldoen.

Veelzijdige toepassingen in alle sectoren

Schroeftransporteurs zijn onmisbaar in een breed scala aan industrieën. Ze stroomlijnen kritische processen en verhogen de productiviteit.

Landbouw

Granen, veevoer, meststoffen

Eten & Drinken

Poeders, kruiden, ingrediënten

Chemische verwerking

Harsen, polymeren, additieven

Mijnbouw & Mineralen

Ertsen, aggregaten, cement

Afval & Recycling

Slib, biomassa, recyclebaar materiaal

Veelvoorkomende toepassingen zijn onder meer: het overbrengen van bulkmateriaal (granen, poeders, pellets), mengbewerkingen (bijvoorbeeld diervoeder), nauwkeurige dosering voor het doseren van ingrediënten en ontwateringsprocessen voor slib en afvalstoffen.

Vraag gedetailleerde informatie en prijzen aan

Vul onderstaand formulier in voor de meest actuele prijzen, levertijden en configuratieopties op maat. Onze specialisten reageren zo snel mogelijk.

Garantie-informatie

Al onze recyclingmachines en schroeftransporteurs worden geleverd met 1 jaar beperkte garantie. Alle producten kunnen worden aangepast aan de specifieke wensen van de klant.