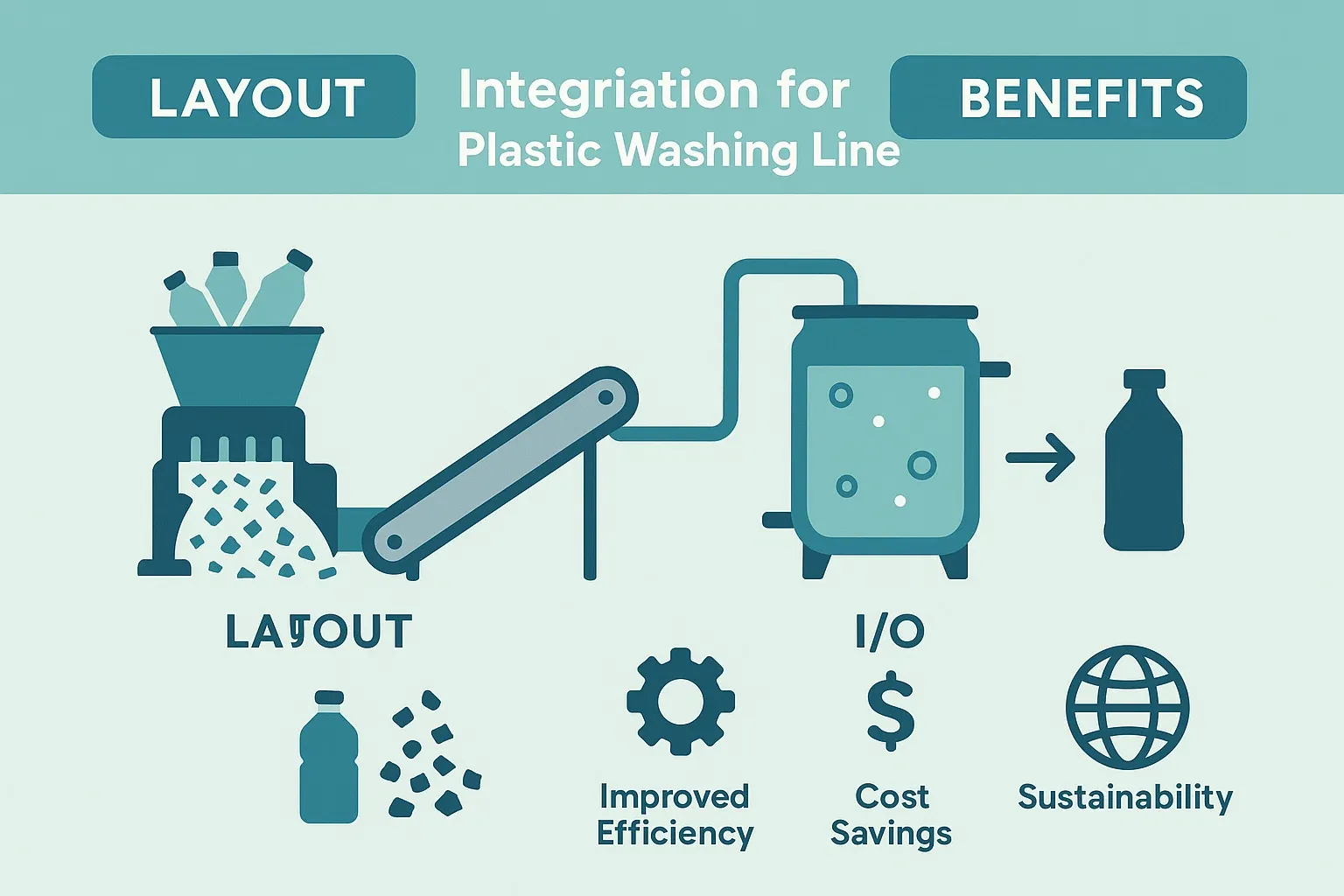

A plastic washing line is a continuous process. A shredder is a batch process. Connecting them directly without buffering and controls often causes instability (surges, starvation, jams) and measurable throughput losses; the magnitude depends on material, feeder design, and downstream tolerance. This guide details practical process integration patterns for feeding a continuous wash line from a batch shredder.

Related equipment: rigid plastic shredder, integrated shredder-granulator machine.

1. The Surge Problem: Batch vs. Continuous

- Shredder Behavior: When a fresh bale is dropped in, amperage spikes, and output surges to 150% of nominal capacity. When the hopper is empty, output drops to 0%.

- Wash Line Requirement: Friction washers and sink-float tanks require a steady, “trickle” feed. Surges cause jams; starvation causes cavitation.

The Solution: Buffer Hopper & Discharge Conveyor

You cannot drop material directly from shredder to washer.

1. Buffer Hopper: A storage silo or large-volume conveyor located between the shredder discharge and the wash line infeed.

* Sizing Rule: Often sized to hold roughly 15-20 minutes of shredder output, depending on bale-loading intervals and downstream tolerance.

2. Variable Speed Discharge: The conveyor exiting the buffer hopper is typically on a VFD (Variable Frequency Drive), controlled by the wash line’s demand, not the shredder’s output.

2. Metal Detection Strategy

Where do you put the magnet?

* Option A: Before Shredder: Protects the shredder.

* Type: Overband Magnet (Ferrous only).

* Option B: After Shredder / Before Granulator: Protects the Granulator (Critical).

* Type: Tunnel Metal Detector. Shredded material is spread thin on a belt. The detector can find small brass/aluminum fragments that the overband missed.

* Mechanism: A “Drop Flap” rejects a small pile of plastic containing the metal, preventing it from exploding the granulator screen.

3. Wet Shredding (Pre-Washing)

Injecting water into the shredder cutting chamber.

* Pros:

1. Blade Life: Water acts as a lubricant, reducing friction heat and edge wear by ~20%.

2. Pre-Wash: The turbulence of the rotor acts as a high-friction washer, removing 60-70% of loose sand/dirt before the material even hits the wash line.

* Cons:

1. Seal integrity: It is common to specify “Wet Package” bearings (labyrinth seals + purge grease) to reduce water ingress risk.

2. Corrosion: The cutting chamber is often specified as stainless (e.g., 304) or hardfaced carbon steel depending on chemistry, water quality, and abrasion.

4. Control Logic (PLC Handshake)

The shredder and wash line PLCs should be interlocked (handshake logic) so faults and starts propagate in a controlled sequence.

* Cascade Stop: If the Friction Washer faults (trips), the logic is typically set up to:

1. Stop the Infeed Conveyor (immediately).

2. Stop the Buffer Discharge (immediately).

3. Pause the Shredder (put it in “Idle Mode”, do not shut down completely).

* Cascade Start: Reverse order. Start Washer -> Start Buffer -> Resume Shredding.

Summary Checklist

| Component | Specification | Purpose |

|---|---|---|

| Infeed | Current-Sensing Conveyor | Pauses feed if Shredder Amps > 90% |

| Discharge | VFD Controlled Belt | Matches feed rate to Washer capacity |

| Protection | Tunnel Metal Detector | Protects downstream Granulator |

| Cleaning | Water Spray Nozzles | Reduces wear and pre-washes film |

References

[1] ISO 15270:2008 Plastics — Guidelines for the recovery and recycling of plastics waste. ISO 15270:2008 Plastics — Guidelines for the recovery and recycling of plastics waste

[2] “Process Control in Waste Management,” IEEE Control Systems. Process Control in Waste Management