Rigid Plastic Washing Line for PP, HDPE, PVC

Configured for rigid PP/HDPE/PVC regrind (crates, caps, pipes, profiles, housings) with labels, oils, glue, and fines. The line integrates pre-wash/sorting, wet granulation, intensive washing, sink-float separation, mechanical dewatering, and thermal drying to produce clean flakes conditioned for extrusion and pelletizing.

- Target residual moisture: typically below 3% (with full drying)

- Contaminants addressed: labels, oils, glue, fines (configuration dependent)

- Typical throughput: 500–2000 kg/h (configuration dependent)

- Layout and utilities sized per project

Selection Criteria

Primary factors that determine module selection, utilities sizing, and output consistency for rigid regrind.

Moisture Target

Discharge moisture is set by the dewatering + thermal drying configuration and the inlet water load. Specify a target to size the drying stage.

Decontamination Level

Cleaning intensity is selected by label load, oil/adhesive contamination, and fines content (cold wash vs. hot wash option).

Material Mix Handling

Sink-float separation and optional air classification are selected based on PP/PE mixes, PVC risk, and light contaminants such as paper/labels.

Water Loop Design

Open or closed-loop water design impacts filtration requirements, wastewater handling, and operating cost. Specify site constraints early.

Wear and Maintenance

Abrasive fines and label glue drive wear protection, screen selection, and maintenance intervals across granulation, friction washing, and dewatering.

Footprint Integration

Conveyor routing, tank length, dryer placement, and access clearances are configured to match your available space and material handling plan.

Supported Materials (Rigid)

Typical rigid plastics this washing line is designed to process.

PP regrind

Rigid PP regrind from crates, caps, household items, and industrial housings. Typical contaminants include labels, oils, and fines.

HDPE regrind

Rigid HDPE regrind from bottles, drums, pipes, and crates. Washing configuration is selected by label load and oil/chemical residue.

PVC regrind

PVC regrind is widely used in pipes, flooring, cable insulation, and window frames due to its durability, chemical resistance, and adaptability for various applications.

ABS regrind

ABS regrind is commonly used in automotive parts, electronics housings, toys, and appliances, valued for its toughness, impact resistance, and excellent surface finish.

Mixed rigid regrind

Mixed rigid streams (e.g., crates, buckets, housings, profiles) can be configured with sorting and separation to meet your quality targets.

PET regrind

Rigid PET (e.g., bottles and trays) can be handled with the right cleaning and separation configuration.

Expandable to film lines

This page focuses on rigid plastics (PP/HDPE/PVC). If your feedstock is mainly LDPE/LLDPE film, raffia, or woven bags, we can propose a dedicated film washing configuration and equipment set.

Process Architecture

Reference sequence from pre-wash through drying. Final configuration depends on contamination profile, target flake size, and downstream extrusion requirements.

Pre‑Washing & Sorting

Pre-wash, remove gross contaminants, and stabilize feed for downstream size reduction and washing.

Granulation

Wet granulation to a defined flake size range to improve washing efficiency and downstream separation.

Intensive Washing

High-shear scrubbing to reduce label glue, oils, and fines carryover before separation and dewatering.

Separation

Density-based separation to reduce heavy contamination and manage mixed streams when specified.

Rinsing & Dewatering

Rinsing and centrifugal dewatering to remove free water and reduce thermal drying load.

Thermal Drying

Thermal drying configured to meet a defined residual moisture target for stable extrusion/pelletizing.

Process Video

See the rigid washing line workflow from pre-washing to drying.

Core Modules

Core machines used to size, wash, separate, dewater, and dry rigid regrind. Final list depends on feedstock and quality targets.

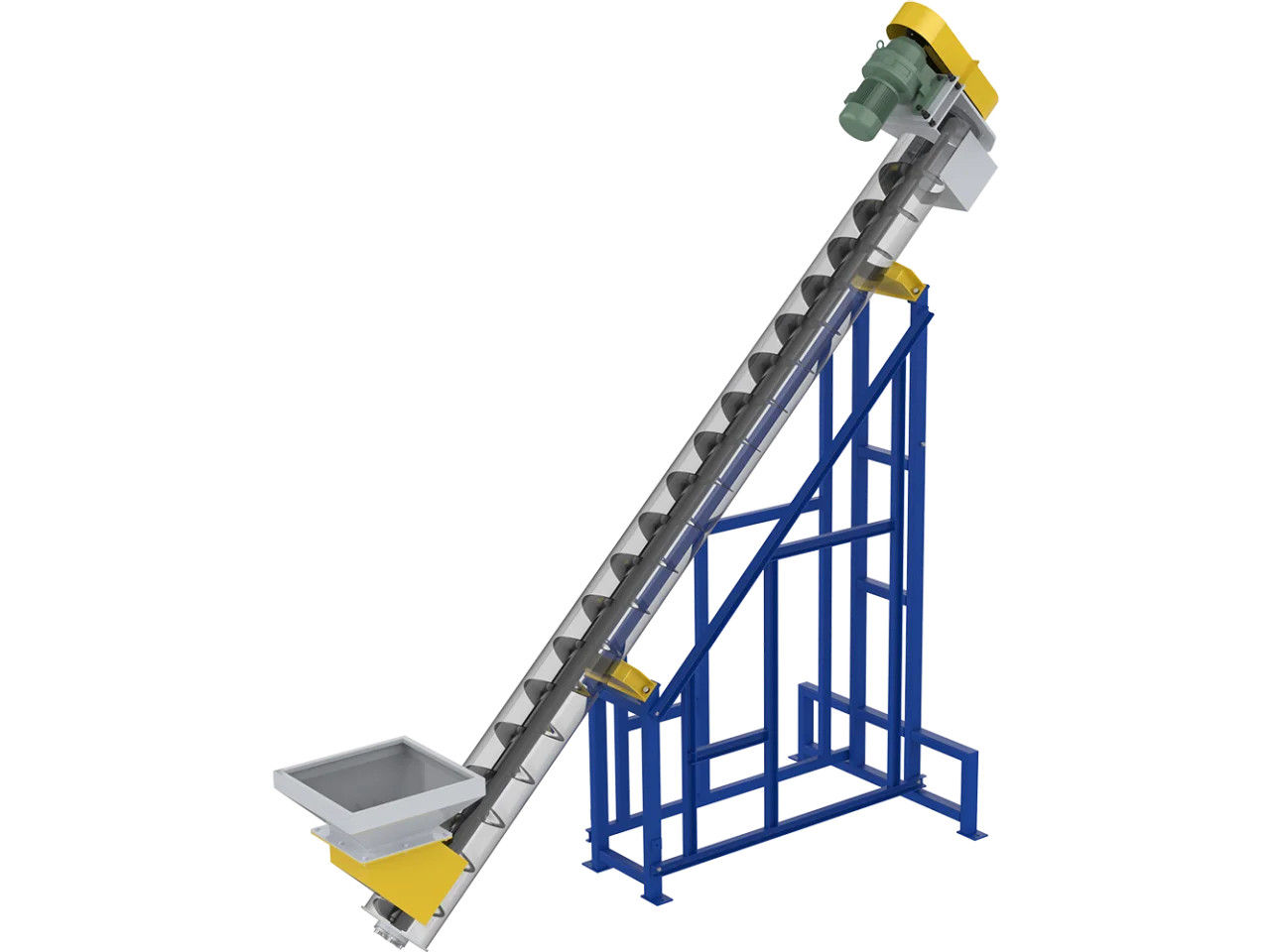

Screw Feeder Specifications

- Material: 304 stainless steel

- Shell & Blade Thickness: 3 mm

- Screen Hole Thickness: 2 mm

- Spiral Diameter: Customized per output

Primary Functions

- Transfers material between stages with controlled residence time

- Manages carryover water and fines between wash stages

- Stabilizes throughput for downstream granulation and washing

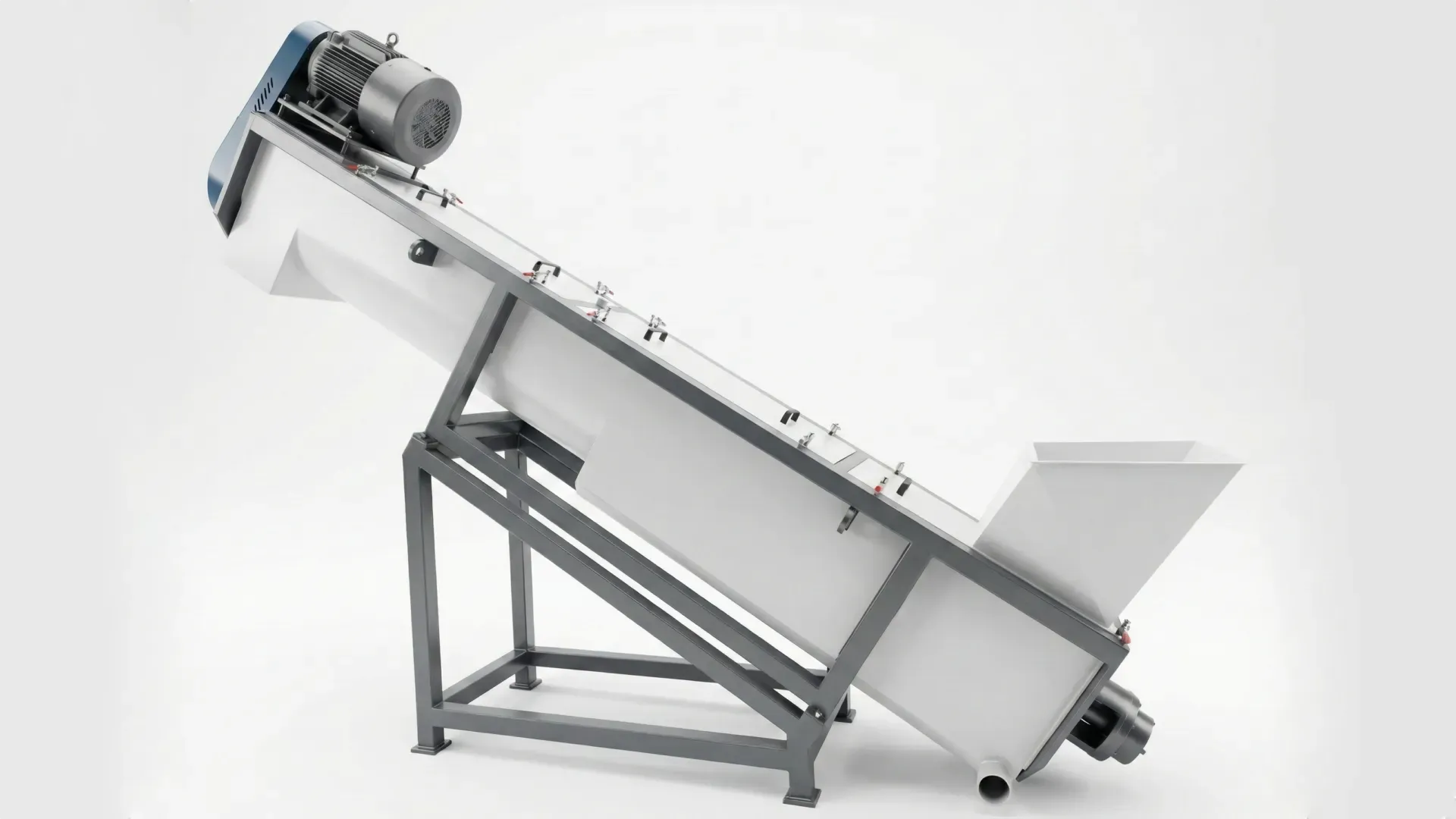

Rigid Plastic Crusher Specifications

- Rotor Speed: 400–600 RPM

- Blade Material: D2 high‑carbon, high‑chromium steel

- Cutting Arrangements: V‑shape or double‑scissor

- Screen Filter Size: 10–100 mm (custom)

Primary Functions

- Produces flakes sized for washing and separation efficiency

- Reduces dust carryover via wet cutting and immediate rinsing

- Improves feeding stability for dewatering and drying stages

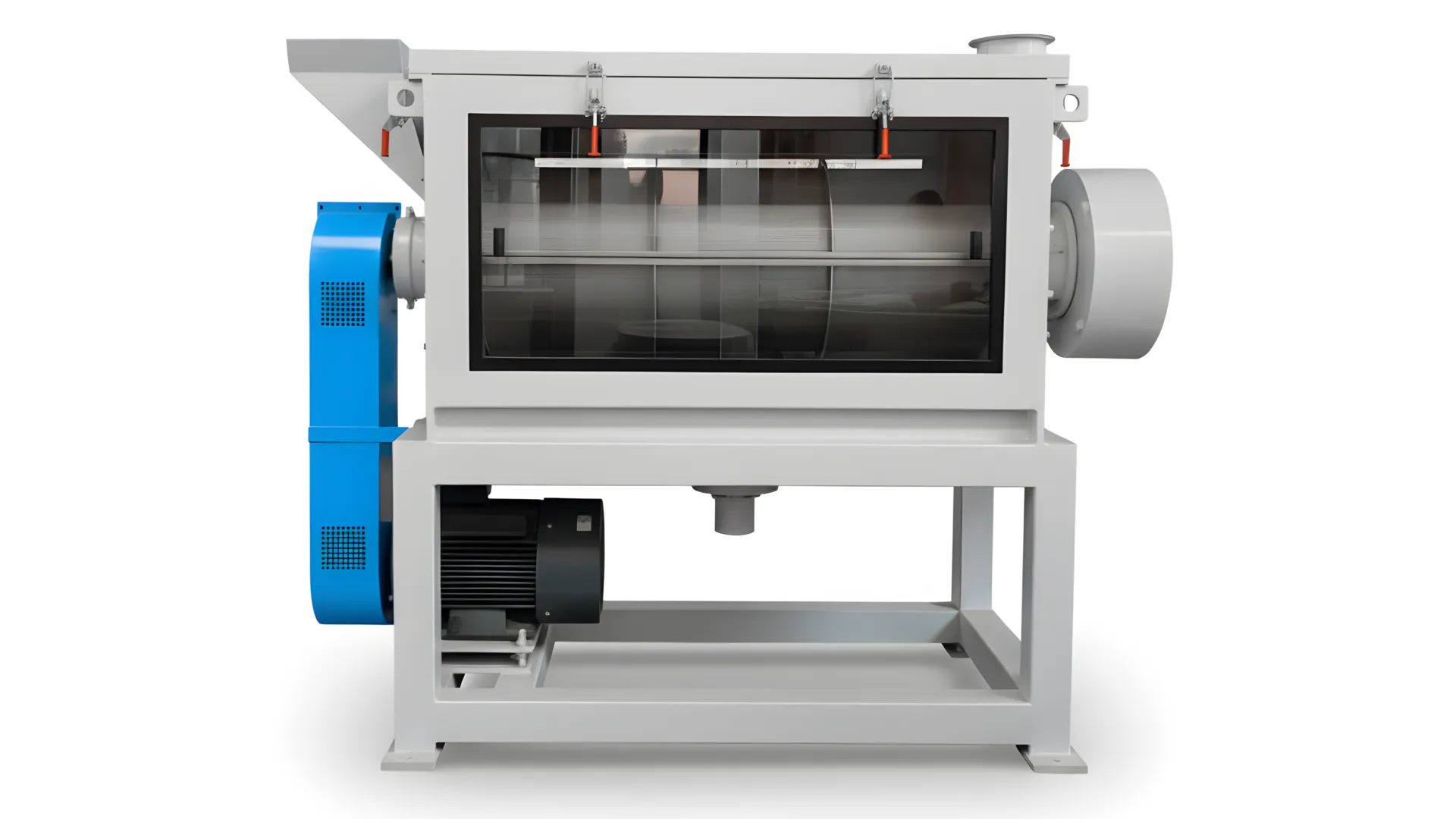

Friction Washer Specifications

- Rotor Speed: 500–600 RPM

- Water System: Top inlet, bottom outlet

- Operation: Continuous

- Cleaning Method: Friction‑based

Primary Functions

- Reduces label glue, oils, and fines on rigid flakes

- Maintains controlled residence time between stages

- Limits abrasive carryover into dewatering and drying

Floating Separation Tank Specifications

- Interior Width: 1000–1800 mm

- Total Length: 4–7 m

- Interior Material: 304 stainless steel

- Exterior Frame: Carbon steel

- Paddle Motors: 1.5 kW × 2 (VFD)

Key Features

- Geometry configured for stable separation and rinsing

- Sectioned design supports staged rinsing and contamination management

- Water loop can be configured for open or closed operation

- Paddle speed control supports residence time tuning

Centrifugal Dryer Dewatering Specifications

- Rotation Speed: ≈ 1,000 RPM

- Moisture Reduction: To ≈ 20–30%

- Main Components: Long shaft with paddles, mesh tunnel

- Casing: Metal container with external motor

Key Features

- Reduces thermal drying load by removing free water mechanically

- Continuous operation for stable line throughput

- Wear protection can be specified for abrasive fines

Thermal Dryer Specifications

- Model: RSJ800

- Blower Power: 5.5 kW

- Heating Power: 36 kW

- Pipe Diameter: ⌀159 mm

- Pipe Material: 304 stainless steel

Key Features

- Continuous drying configured for a defined moisture target

- Cyclone separation helps manage fines and lightweight carryover

- Airflow and heat input sized by throughput and inlet moisture

- Multi-stage drying can be specified for higher capacity

Technical Parameters

Key outputs and configuration points for rigid PP/HDPE/PVC washing.

| Supported materials | Rigid PP/HDPE/PVC regrind; ABS and rigid PET are supported with the right separation and cleaning setup. |

|---|---|

| Typical output moisture | Target sub‑3% residual moisture with the full line and proper process tuning. |

| Process stages | Pre‑wash & sorting → granulation → intensive washing → sink‑float separation → rinsing & dewatering → thermal drying. |

| Utilities | Closed-loop water design and optimized power usage, sized to your throughput and contamination level. |

| Configuration | Throughput, layout, tank length, drying capacity, and separation options are customized per project. |

| Capacity (kg/h) | Install Power (kW) | Typical Layout Area (m²) | Operators / Shift | Steam Pressure (MPa) | Process Water (m³/h) |

|---|---|---|---|---|---|

| 500 | 162 | 500 | 4 | 0.6-0.8 | 3 |

| 1000 | 250 | 800 | 4 | 0.6-0.8 | 4 |

| 2000 | 368 | 1000 | 4 | 0.6-0.8 | 5 |

Note: Values are indicative. Final utilities depend on contamination profile, optional hot washing/heating selection, and drying configuration.

Utilities guidance: electrical supply is specified by voltage/Hz and start method; water demand depends on open vs closed loop design and filtration/wastewater handling requirements.

Delivery Scope

What you typically receive with a rigid washing line project.

- Core equipment set (feeding, granulation, washing, separation, dewatering, drying) per your agreed configuration

- Electrical control cabinet and interlocks (configured to your site voltage and safety requirements)

- Process layout support (foundation guidance, utilities plan, and line arrangement)

- Commissioning guidance and operator training (on-site or remote, depending on project)

- Spare parts and documentation package (manuals, wiring, and maintenance guidance)

Typical Performance Targets

Reference targets used to size modules and validate performance. Actual results depend on feedstock and configuration.

Residual moisture target

Contamination management

Throughput stability

Frequently Asked Questions

Decision-oriented answers for selecting modules, utilities, and output targets.

Which regrind materials are supported?

This line is optimized for rigid PP/HDPE/PVC regrind (crates, caps, bottles, pipes, profiles). ABS and rigid PET are supported with the right separation. For mainly LDPE/LLDPE film or raffia, ask us for a dedicated film washing configuration.

What output moisture can I expect?

Residual moisture is typically below 3% with dewatering + thermal drying when required for stable extrusion/pelletizing (feedstock dependent).

Can the system fit our plant layout?

Yes. Layout, tank length, conveyor routing, and dryer placement are configured around capacity, utilities, and available footprint.

How about installation and training?

Commissioning support can be on-site or remote, including operator training, interlocks verification, and process tuning to meet moisture and cleanliness targets.

RFQ Inputs

Provide the minimum inputs below so we can size modules, utilities, and layout for your rigid regrind stream.

- Feedstock type(s): PP/HDPE/PVC, mixed rigid, label load, oil/adhesive contamination, fines content

- Target throughput (kg/h) and operating hours per day

- Target output: flake size range and moisture requirement for extrusion/pelletizing

- Utilities available: voltage/Hz, water loop preference (open/closed), wastewater constraints

- Space constraints: available length/width, elevation limits, material handling constraints

- Optional modules: hot wash, air classification, additional rinsing/filtration