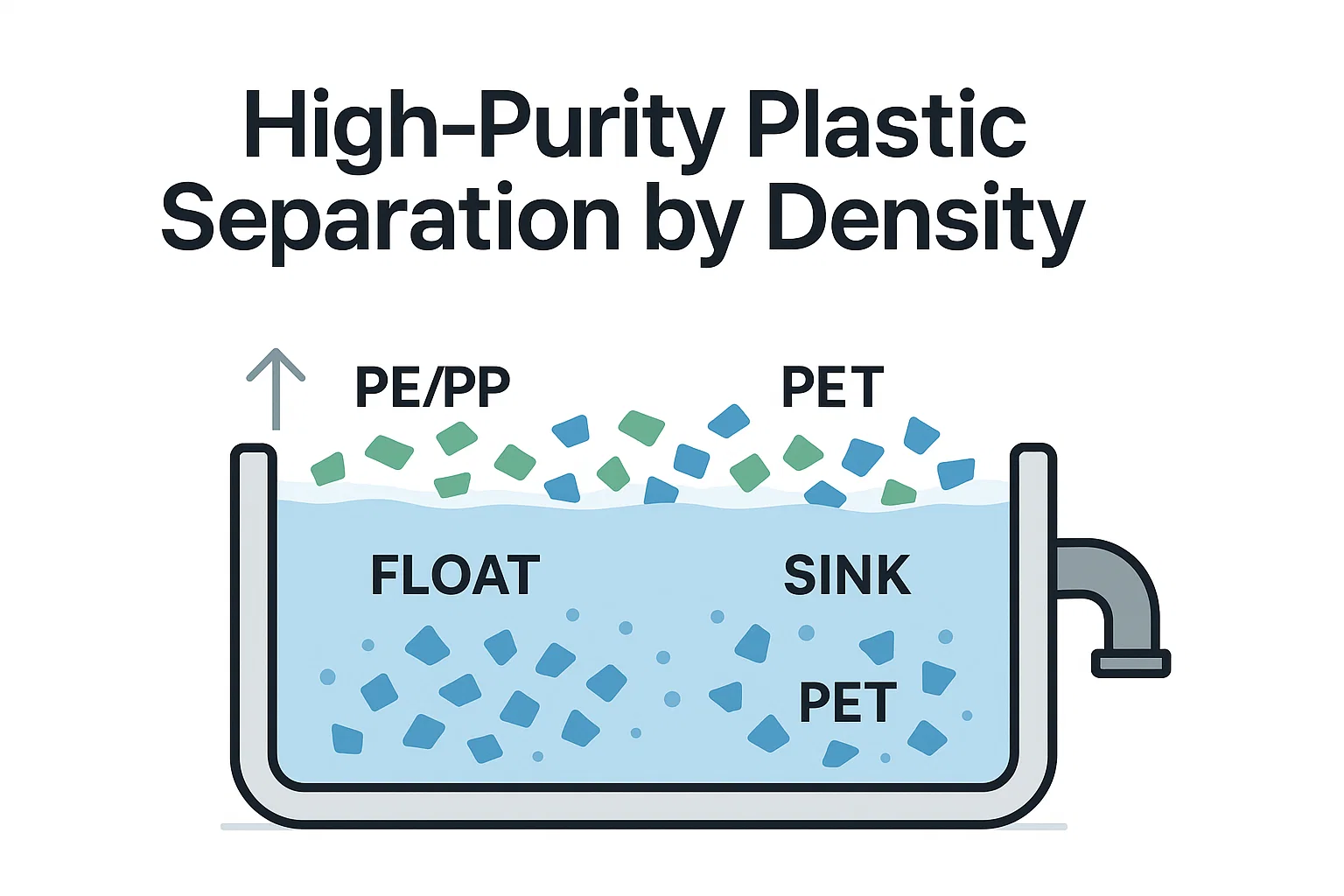

Sink-Float Separation Tank for Plastic Recycling

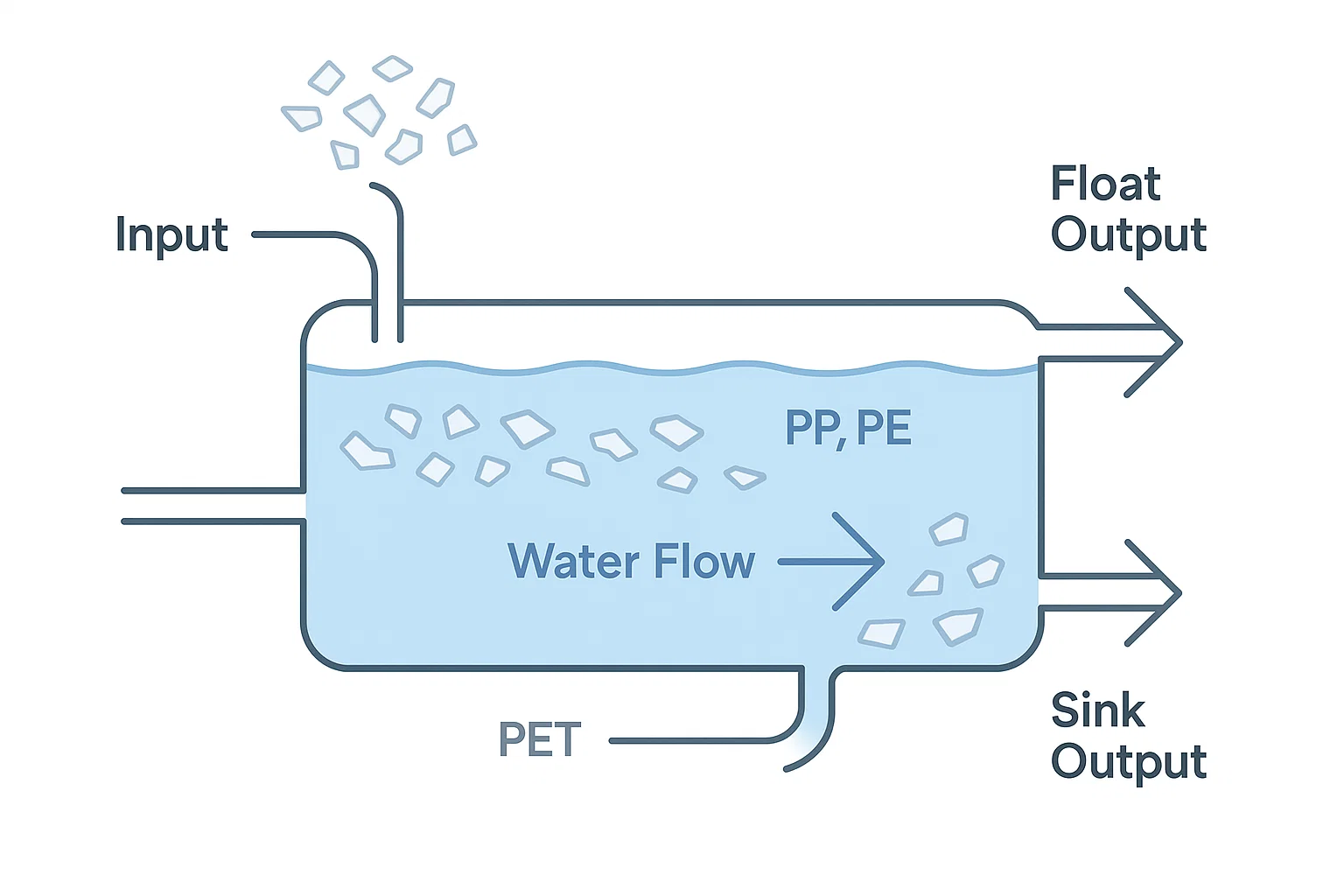

Energycle’s sink-float separation technology uses material density differences to efficiently separate mixed plastic flakes, ensuring high-purity output and improved recycling value.

Density Reference Table

| Material | Density (g/cm³) | Behavior in Water |

|---|---|---|

| PP (Polypropylene) | 0.85 – 0.90 | Floats |

| PE (Polyethylene) | 0.91 – 0.97 | Floats |

| PET (Polyethylene Terephthalate) | 1.38 – 1.41 | Sinks |

| PVC (Polyvinyl Chloride) | 1.30 – 1.58 | Sinks |

Typical Applications

- PET Bottle Recycling – Separate PET body flakes from floating PP/PE caps and labels

- WEEE (Electronic Waste) – Classify ABS, PS, PVC, PC in shredded electronics

- Automotive Plastic Recovery – Sort plastics from bumpers, dashboards, and panels

- Post-Consumer Packaging – Clean separation of rigid plastic containers

- Mixed Polyolefin Streams – Fine-tuned fluid density to sort PE vs. PP (optional)

Benefits of Our System

- High-precision density-based separation

- Clean, high-value recyclate output

- Automated skimmer and screw conveyor systems

- Efficient water recirculation and filtration

- Durable, corrosion-resistant stainless steel construction

Frequently Asked Questions (FAQ)

What types of plastics can be separated using this tank?

The tank is primarily designed to separate plastics based on density, including PET (sinks), PP, and PE (float). It can also help separate other polymers like PVC, PS, and ABS with proper fluid tuning.

Do I need to use saltwater instead of regular water?

For most applications (e.g., separating PET from PP/PE), clean water is sufficient. However, saltwater (brine) may be used if you need to fine-tune the liquid’s density for more precise separations.

Is the system fully automated?

Yes, Energycle’s Sink-Float Separation Tank includes automated feeding, agitation, skimming, bottom extraction, and water recirculation to minimize manual labor and maximize throughput.

Can this tank be integrated into existing recycling lines?

Absolutely. Our tanks are designed for easy integration with standard washing lines, granulators, dryers, and extrusion systems. Custom configurations are also available.