PET Bottle Recycling Washing Line

Automated system processes contaminated PET bales into 99.5% pure rPET flakes. Reduces operating costs through efficient water recycling and labor-saving automation. Output meeting standards for fiber and bottle-to-bottle applications.

Get a Technical ProposalOvercome Recycling Inefficiencies

Traditional systems often suffer from high contamination rates and excessive maintenance costs. Our design addresses these specific mechanical and process failures.

Challenge: High Contamination

Solution: Multi-stage hot washing and high-speed friction scrubbing remove glue, oil, and labels. The process consistently achieves 99.5% flake purity.

Challenge: High Operational Costs

Solution: Water filtration reduces consumption by 50%. Automated controls lower labor requirements by 2-3 operators per shift.

Challenge: Frequent Downtime

Solution: Critical components use D2/SKD-11 alloy and SUS304 stainless steel. This heavy-duty construction minimizes wear and maintenance intervals.

System Capabilities

<100ppm Impurity

Produce rPET flakes with <100ppm total impurities. Material meets premium grade standards.

PLC Automation

PLC system enables precise control and real-time monitoring. Automation limits human error.

Resource Efficiency

Recirculating water system minimizes waste. Energy-efficient motors reduce power consumption.

Heavy-Duty Construction

Built with durable materials for continuous 24/7 operation. Requires minimal maintenance.

Customizable Capacity

Configurations available from 500 to 6,000 kg/h. Designs adapt to specific plant layouts.

Comprehensive Support

Includes plant design, installation, and operator training. Technical support available for the machine's lifetime.

Process Overview

Sequential washing and separation stages ensure consistent output quality.

1. Automated Bale Breaker

Function: Breaks apart compressed PET bottle bales. Ensures a steady, metered flow of material into the line.

Configuration:

- High-torque motors

- Adjustable speed control

- Heavy-duty frame

2. Trommel Screen

Function: Removes heavy contaminants like sand, glass, and metal. Separates loose caps and labels through tumbling action.

Configuration:

- Customizable screen perforations

- Wear-resistant internal drum

- Optimized rotation angle

3. Wet Granulator (Crusher)

Function: Crushes bottles into uniform flakes. Uses water to cool blades and flush initial contaminants.

Configuration:

- V-type rotor design

- D2/SKD-11 hardened steel blades

- Interchangeable screens

4. Hot Washer System

Function: Dissolves glue, oil, and residues using 85-95°C water and chemical agents. High-friction agitation ensures thorough cleaning.

Configuration:

- SUS304 stainless steel tank

- High-speed agitator

- Auto-dosing system

5. Sink/Float Separation Tank

Function: Separates heavy PET flakes from lighter PP/PE caps and labels using water density. Paddles move floating material to discharge.

Configuration:

- Full SUS304 construction

- Surface-skimming paddles

- Bottom screw conveyor

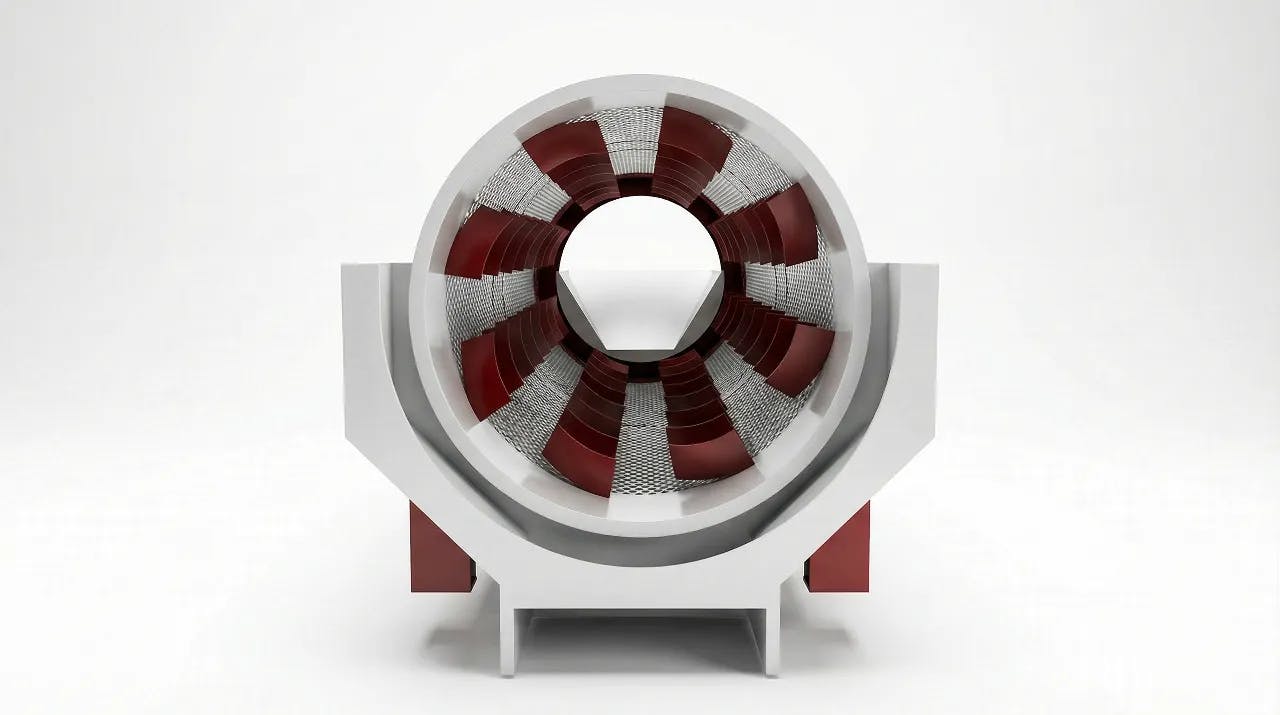

6. Dewatering & Thermal Drying

Function: Removes moisture in two stages. Centrifugal force removes bulk water, followed by hot air drying to <1% moisture.

Configuration:

- High-speed dynamic rotor

- Temperature control system

- Stainless steel piping

System in Action

Observe the transformation from post-consumer bottles to clean flakes.

Commercial Applications

Polyester Staple Fiber (PSF)

Raw material for textiles, carpets, and non-woven fabrics.

Bottle-to-Bottle Recycling

Production of new food-grade beverage bottles.

PET Strapping

Manufacturing of high-strength industrial packaging straps.

PET Sheet & Film

For thermoformed packaging, trays, and food containers.

What Our Clients Say

“Since installing this PET washing line, the quality of our flakes has improved dramatically, allowing us to sell them at a 15% premium. The system's stability and high degree of automation have exceeded our expectations.”

— David Chen, Director of Operations, Major Southeast Asian Recycler

“We are extremely satisfied with our production line. The team was professional from the initial consultation through final installation. Most importantly, their water circulation system has saved us a significant amount on utility costs.”

— Maria Garcia, Plant Manager, Plastics Manufacturer in Mexico

Performance Comparison

| Feature | Our System | Standard / Budget Systems |

|---|---|---|

| Final Purity | <100 ppm (Food-grade achievable) | >500 ppm (High contamination, low value) |

| Washing Technology | Hot chemical wash + high-speed friction | Cold water rinsing only |

| Automation Level | Full PLC intelligent control | Manual controls, labor-intensive |

| Water Consumption | Low consumption with water filtration & recycling | High consumption with constant discharge |

| Machine Lifespan | Wear-resistant steel & stainless steel components | Standard carbon steel, prone to rust & corrosion |

Technical Specifications

Final Flake Quality Standards

| Parameter | Guaranteed Value |

|---|---|

| Total Impurity | <100 ppm |

| PVC Content | <50 ppm |

| PP/PE Content | <20 ppm |

| Metal Content | <20 ppm |

| Moisture Content | <1% |

| Flake Size | 12-16mm (Customizable) |

Production Line Models & Configurations

| Capacity (kg/h) | Installed Power (kW) | Required Area (m²) | Required Staff | Water Consumption (m³/h) |

|---|---|---|---|---|

| 500 | 220 | 400 | 2-3 | 1 |

| 1000 | 500 | 750 | 3-4 | 3 |

| 2000 | 700 | 1000 | 4-5 | 5 |

| 3000 | 900 | 1500 | 5-6 | 6 |

| 6000 | 1200 | 2500 | 6-8 | 10 |

Frequently Asked Questions

Find answers to common questions about our PET recycling lines.

What types of PET bottles can this line process?

The line processes various post-consumer bottles, including soft drink, water, and oil bottles. We configure additional pre-washing units for heavily contaminated materials.

What is the lead time for a complete system?

Standard lead time is 60-90 days. This timeline varies based on capacity and specific customization requirements.

Do you provide installation and training?

Yes. Our engineering team handles on-site installation, commissioning, and testing. We also train operators and maintenance staff.

What is the warranty policy?

Equipment includes a one-year warranty on manufacturing and materials. We provide free replacement parts during this period and offer lifetime technical support.

How much does the system cost?

Price depends on capacity and automation level. Contact our engineering team for a specific quotation based on your raw material and output requirements.

Ready to Upgrade Your Recycling Business?

Contact us for a technical proposal and quotation. Our team responds within 24 hours.