Effectief afvalbeheer is een hoeksteen van bloeiende gemeenschappen en een gezond milieu. De kern van dit cruciale proces wordt gevormd door gespecialiseerde recyclingapparatuur die onvermoeibaar werkt aan de efficiënte verwerking van afvalstoffen, waaronder specifieke machines die zijn ontworpen voor materialen zoals EPS (geëxpandeerd polystyreen). EPS-schuim hydraulische verdichtingsmachineMaar zoals bij alle hardwerkende machines zijn de levensduur en optimale prestaties afhankelijk van één belangrijke factor: nauwkeurig onderhoud.

Het verwaarlozen van uw EPS-recyclingapparatuur leidt niet alleen tot kostbare reparaties en onverwachte uitval, maar kan ook gevolgen hebben voor uw operationele efficiëntie en veiligheidsnormen. Deze gids biedt waardevolle, praktische tips om u te helpen bij het opzetten van een gedegen onderhoudsroutine voor uw afvalverwerkingsapparatuur, zodat deze jarenlang soepel blijft werken.

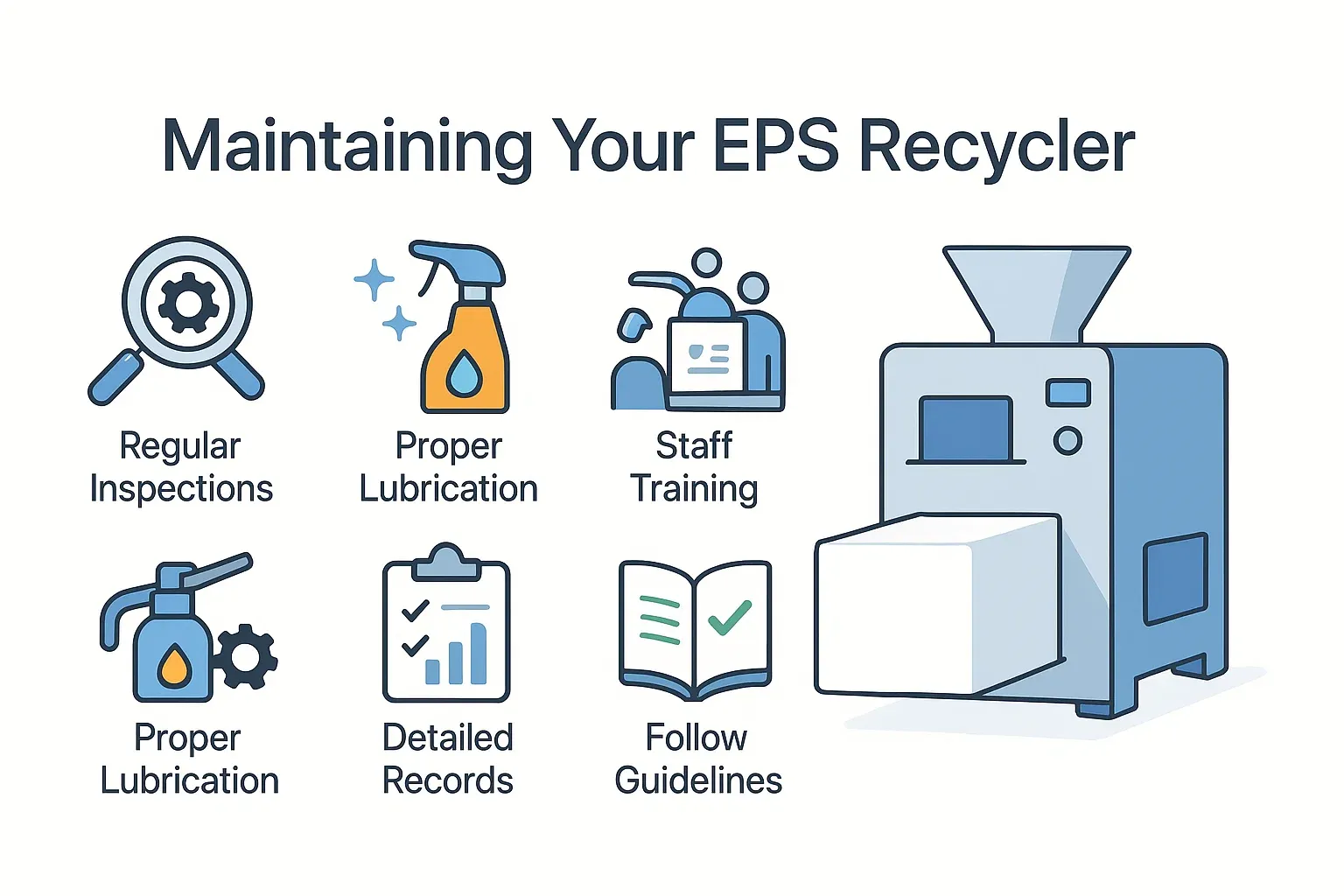

1. Proactieve zorg: de kracht van regelmatige inspecties

Beschouw regelmatige inspecties als uw eerste verdedigingslinie tegen ernstige apparatuurstoringen. Een consistent inspectieschema stelt u in staat om kleine problemen op te sporen voordat ze uitgroeien tot ernstige problemen, met name cruciaal voor machines die specifieke materialen zoals EPS verwerken.

- Waar moet je op letten: Voer grondige visuele controles uit op tekenen van slijtage, schade, losse verbindingen of mogelijke storingen. Besteed veel aandacht aan kritische componenten zoals:

- Transportbanden (scheuren, problemen met de geleiding, spanning, ophoping van EPS-resten)

- Messen, snijmessen of persplaten (scherpte, splinters, integriteit, harsvorming)

- Hydraulische systemen (lekken, staat van de slangen, vloeistofniveaus – essentieel voor verdichtingsmachines)

- Motoren en versnellingsbakken (ongebruikelijke geluiden, oververhitting)

- Veiligheidsvoorzieningen en noodstops

- Ontwikkel een systeem: Maak een uitgebreide inspectiechecklist op maat voor elk stuk EPS-recyclingapparatuur. Dit garandeert consistentie en grondigheid, ongeacht wie de inspectie uitvoert.

- Er zijn bekwame ogen nodig: Zorg ervoor dat u technici in dienst heeft, zowel interne als externe, die bekwaam zijn in het nauwkeurig diagnosticeren van potentiële problemen. Ze moeten beschikken over het juiste gereedschap en originele onderdelen voor eventuele reparaties. Een vroege en nauwkeurige diagnose is essentieel om langdurige downtime te voorkomen.

2. Een schone machine is een gelukkige machine: het belang van dagelijkse reiniging

EPS-recyclingapparatuur, zoals verdichtingsmachines of verdichtingsmachines, wordt voortdurend blootgesteld aan polystyreendeeltjes, stof en soms lijm of verontreinigingen van het ingezamelde EPS. Deze dagelijkse belasting kan leiden tot:

- Verstopping: EPS-stof en kleine fragmenten kunnen zich ophopen en bewegende onderdelen, sensoren of smeltkamers blokkeren.

- Ophoping van residu: Gesmolten EPS kan resten achterlaten op verwarmingselementen of personderdelen als dit niet goed wordt behandeld.

- Verhoogde slijtage: Schurende verontreinigingen in EPS kunnen de slijtage van oppervlakken versnellen.

Voer een dagelijks schoonmaakregime in:

- Verwijder los EPS-afval, stof en aangekoekte materialen van alle bereikbare onderdelen.

- Concentreer u op gebieden die gevoelig zijn voor ophoping, zoals rondom lagers, in schroeftoevoersystemen, in verdichtingskamers en onder beschermingsmechanismen.

- Gebruik altijd de door de fabrikant van de apparatuur aanbevolen reinigingsmiddelen en -gereedschappen om schade aan gevoelige componenten of het vervallen van garanties te voorkomen. Regelmatige reiniging verlengt niet alleen de levensduur van uw EPS-machine, maar speelt ook een essentiële rol bij het behoud van de operationele efficiëntie, outputkwaliteit en veiligheid.

3. Soepele werking: de juiste smering beheersen

Smering is de levensader van elke machine met bewegende delen. In de veeleisende omgeving van EPS-recycling is goede smering absoluut cruciaal voor componenten zoals lagers, tandwielen en hydraulische systemen.

- Waarom het belangrijk is: Adequate smering vermindert de wrijving tussen bewegende componenten, voorkomt oververhitting en minimaliseert voortijdige slijtage. Zonder smering kunnen onderdelen vastlopen, wat kan leiden tot catastrofale defecten.

- Volg de gids: Houd u strikt aan de specificaties van de fabrikant met betrekking tot smeermiddelen, toepassingspunten en intervallen voor uw specifieke EPS-apparatuur.

- Controleren en opnieuw controleren: Controleer regelmatig het smeermiddelpeil en vul het indien nodig bij of vervang het.

- De Goudlokje Zone: Houd er rekening mee dat oversmering net zo schadelijk kan zijn als ondersmering. Overtollig smeermiddel kan EPS-stof en verontreinigingen aantrekken of afdichtingen beschadigen. Streef naar de juiste balans om uw apparatuur efficiënt te laten werken.

4. Geef uw team meer macht: de waarde van uitgebreide training

Uw personeel staat aan de frontlinie van de bediening van apparatuur en vaak ook van het eerste onderhoud. Goede training is een investering die zich ruimschoots terugbetaalt, vooral bij gespecialiseerde machines zoals EPS-recyclers.

- Apparatuurspecifieke kennis: Zorg ervoor dat alle operators en onderhoudsmedewerkers grondig zijn opgeleid in de specifieke operationele procedures (inclusief de details van de materiaaltoevoer voor EPS) en de onderhoudsvereisten voor elk stuk EPS-recyclingapparatuur waarmee ze werken.

- Verminder menselijke fouten: Goed geïnformeerde medewerkers zullen apparatuur minder snel verkeerd gebruiken of onjuiste onderhoudstaken uitvoeren, wat kan leiden tot schade, slechte verdichting/verdichting of veiligheidsrisico's.

- Blijf op de hoogte: De EPS-recyclingindustrie en de bijbehorende apparatuurtechnologie zijn voortdurend in ontwikkeling. Bied voortdurende training en bijscholing aan om uw team op de hoogte te houden van best practices, nieuwe veiligheidsprotocollen en ontwikkelingen in onderhoudstechnieken.

5. Volg uw succes: het belang van gedetailleerde onderhoudslogboeken

Het nauwkeurig bijhouden van gegevens over alle onderhoudsactiviteiten is meer dan alleen een kwestie van goed huishouden; het is een strategische troef voor uw EPS-recyclingactiviteiten.

- Bouw een geschiedenis: Documenteer elke inspectie, reiniging, smering, reparatie en vervanging van onderdelen van elke EPS-machine. Vermeld data, een beschrijving van het uitgevoerde werk, wie het heeft uitgevoerd en welke onderdelen zijn gebruikt.

- Patronen identificeren: Met deze gegevens kunt u terugkerende problemen (bijvoorbeeld frequente blokkades vanwege verontreinigde EPS) identificeren, mogelijke toekomstige problemen voorspellen en slijtagecycli voor specifieke componenten begrijpen.

- Geïnformeerde besluitvorming: Deze historische gegevens zijn van onschatbare waarde voor het oplossen van problemen, het plannen van preventieve onderhoudsschema's en het nemen van weloverwogen beslissingen over upgrades of vervangingen van apparatuur.

- Garantie-naleving: Gedetailleerde logboeken zijn vaak essentieel voor het valideren van garantieclaims bij apparatuurfabrikanten.

6. De fabrikant weet het het beste: naleving van officiële richtlijnen

De fabrikant van uw EPS-apparatuur biedt niet voor niets gedetailleerde handleidingen en richtlijnen aan. Deze zijn ontworpen om de prestaties, levensduur en veiligheid van uw machines te maximaliseren.

- Uw go-to-bron: Volg altijd de aanbevelingen van de fabrikant op voor de bediening, reiniging, smering en het routinematige onderhoud van uw EPS-verdichtingsmachine, -verdichtingsmachine of -versnipperaar.

- Garantiebescherming: Als u van deze richtlijnen afwijkt, kan uw garantie komen te vervallen en bent u aansprakelijk voor mogelijk dure reparaties.

- Prestaties optimaliseren: Als u het officiële advies opvolgt, weet u zeker dat uw apparatuur EPS zo efficiënt en effectief verwerkt als bedoeld.

- Veiligheid voorop: De richtlijnen van de fabrikant bevatten vrijwel altijd essentiële veiligheidsinformatie en -procedures. Het negeren hiervan kan leiden tot gevaarlijke bedrijfsomstandigheden. Zorg ervoor dat alle documentatie van de fabrikant gemakkelijk toegankelijk is voor uw operationele en onderhoudsteams.

Investeer in onderhoud en pluk de vruchten

Goed en consistent onderhoud van uw EPS-recyclingapparatuur is geen kostenpost, maar een investering. Door het zorgvuldig uitvoeren van regelmatige inspecties, dagelijkse reinigingsprotocollen, adequate smering, continue training van uw personeel, gedetailleerde administratie en naleving van de richtlijnen van de fabrikant, kunt u aanzienlijk:

- Verleng de levensduur van uw waardevolle machines.

- Minimaliseer kostbare downtime en productieverliezen.

- Verbeter de operationele efficiëntie en de kwaliteit van gerecycled EPS.

- Verbeter de veiligheid voor uw operators.

- Bespaar geld op de lange termijn door grote storingen te voorkomen.

Uiteindelijk draagt een goed onderhouden vloot van EPS-recyclingapparatuur bij aan een duurzamer, efficiënter en winstgevender afvalbeheerproces.

Bent u klaar om de prestaties van uw EPS-apparatuur te optimaliseren?

Bij Energycle begrijpen we de cruciale rol die goed onderhouden machines, zoals uw EPS-recyclingsystemen, spelen in uw succes. Ons wereldwijde netwerk van engineers beschikt over tientallen jaren gespecialiseerde ervaring in afvalbeheer en recyclingapparatuur. Wij kunnen u helpen bij het ontwikkelen en implementeren van effectieve onderhoudsstrategieën om uw activiteiten soepel, veilig en efficiënt te laten verlopen.

Neem contact op met Energycle Ontdek vandaag nog hoe onze expertise uw investering kan beschermen en uw EPS-recyclingmogelijkheden kan verbeteren!