Cutter Compactor Pelletizer Recycling Line

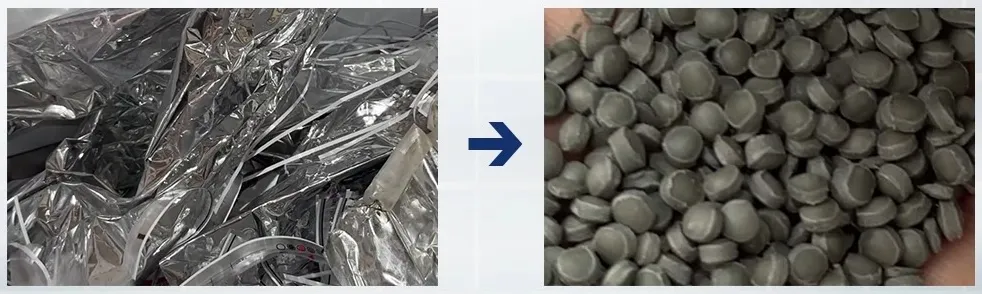

Turn low-bulk-density PE/PP film scrap into uniform pellets with a compact, high-efficiency cutter compactor pelletizer system. Stable feeding, effective degassing, and reliable water-ring pelletizing help maximize output and pellet quality.

Get a Quote / Custom SolutionSystem Video

Performance Benefits

High Efficiency

Process a wide range of materials with high output rates from 180 to 1500 kg/h.

Cost-Effectiveness

Reduce labor costs and save up to 30% on energy consumption with our automated system.

Sustainability

Transform plastic waste into valuable resources, contributing to a circular economy.

Customization

We offer customized solutions to meet your specific needs and material requirements.

Feedstock Range

This cutter compactor pelletizer line is designed for low bulk density soft plastics and light scrap, including:

- PE & PP Films (HDPE, LDPE, LLDPE)

- Woven & Non-Woven Bags (Raffia)

- Foamed Materials (EPE Foam)

- Agricultural Film

- Film Rolls & Edge Trims

- PP Fiber & Yarn

- PE Fruit Nets & Sheets

- Lightly Printed Film Waste

For other materials like PET or rigid plastics, please consult our experts for a customized recycling solution.

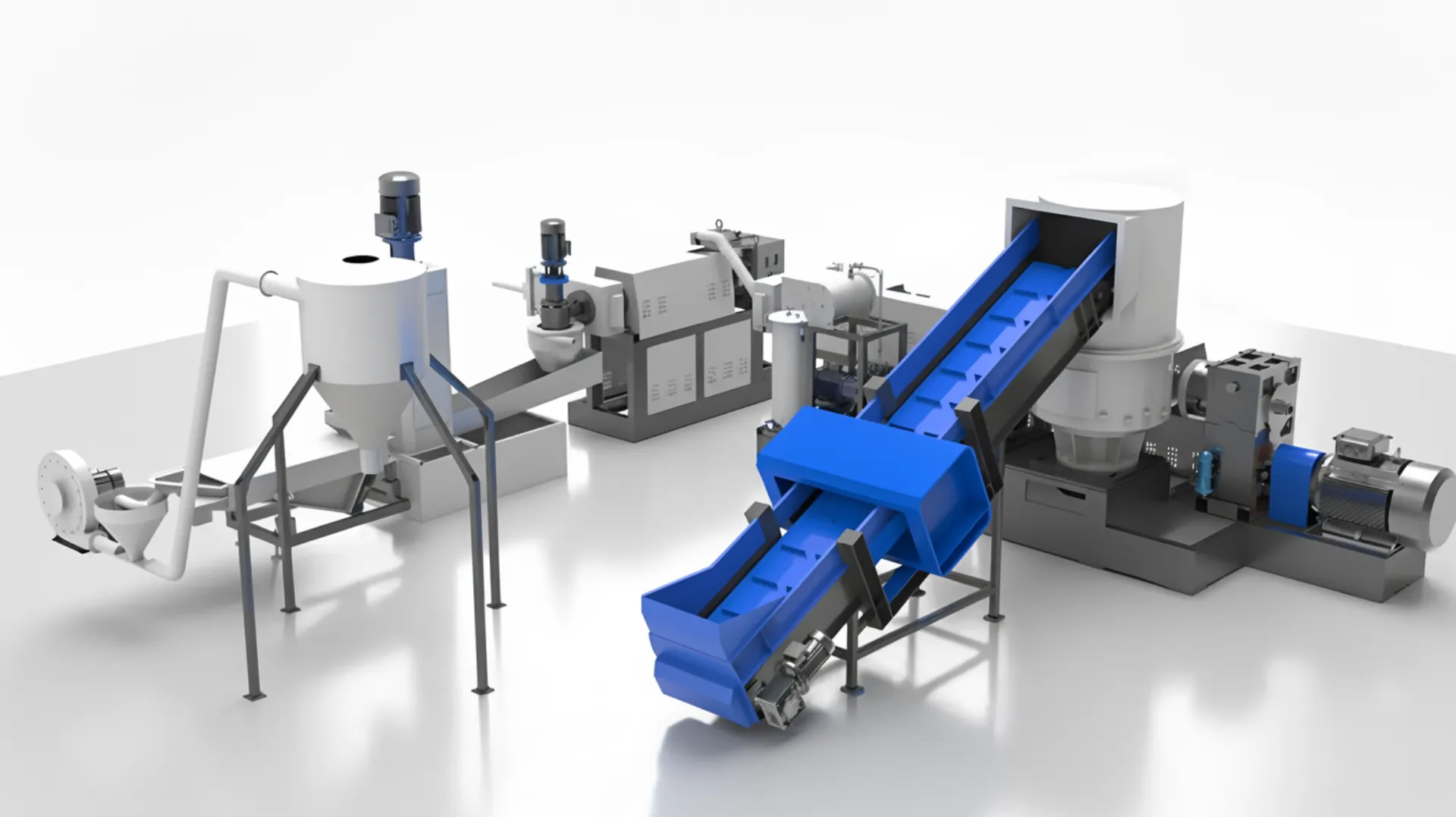

Process Flow

- Feeding: A belt conveyor transports scraps into the compactor, with an integrated metal detector for purity.

- Compaction: Rotating blades cut, mix, and compact the material using frictional heat, ensuring stable feeding.

- Extrusion & Degassing: A single-screw extruder melts the material while a double-zone vacuum system removes volatiles.

- Pelletizing: A water-ring die-face cutting system produces uniform, high-quality pellets.

- Drying: An advanced dewatering system efficiently dries the pellets with minimal energy consumption.

System Configuration

Integrated Design

A smart combination of the agglomerator/cutter-compactor and the extruder in one unit.

Multiple Screw Sizes

Choose from a range of screw diameters to match your specific output requirements.

Venting Extruder

Advanced degassing functionality ensures a moisture-free and pure final product.

Adjustable Pellet Size

The cutting system is designed for flexibility, allowing you to adjust the pellet size.

Capacity & Models

| Model | Output (kg/h) |

|---|---|

| GL85 | 180-250 |

| GL100 | 300-400 |

| GL130 | 500-600 |

| GL160 | 700-800 |

| GL180 | 1000-1500 |

Note: Output capacity may vary. Please contact us for a personalized quotation.

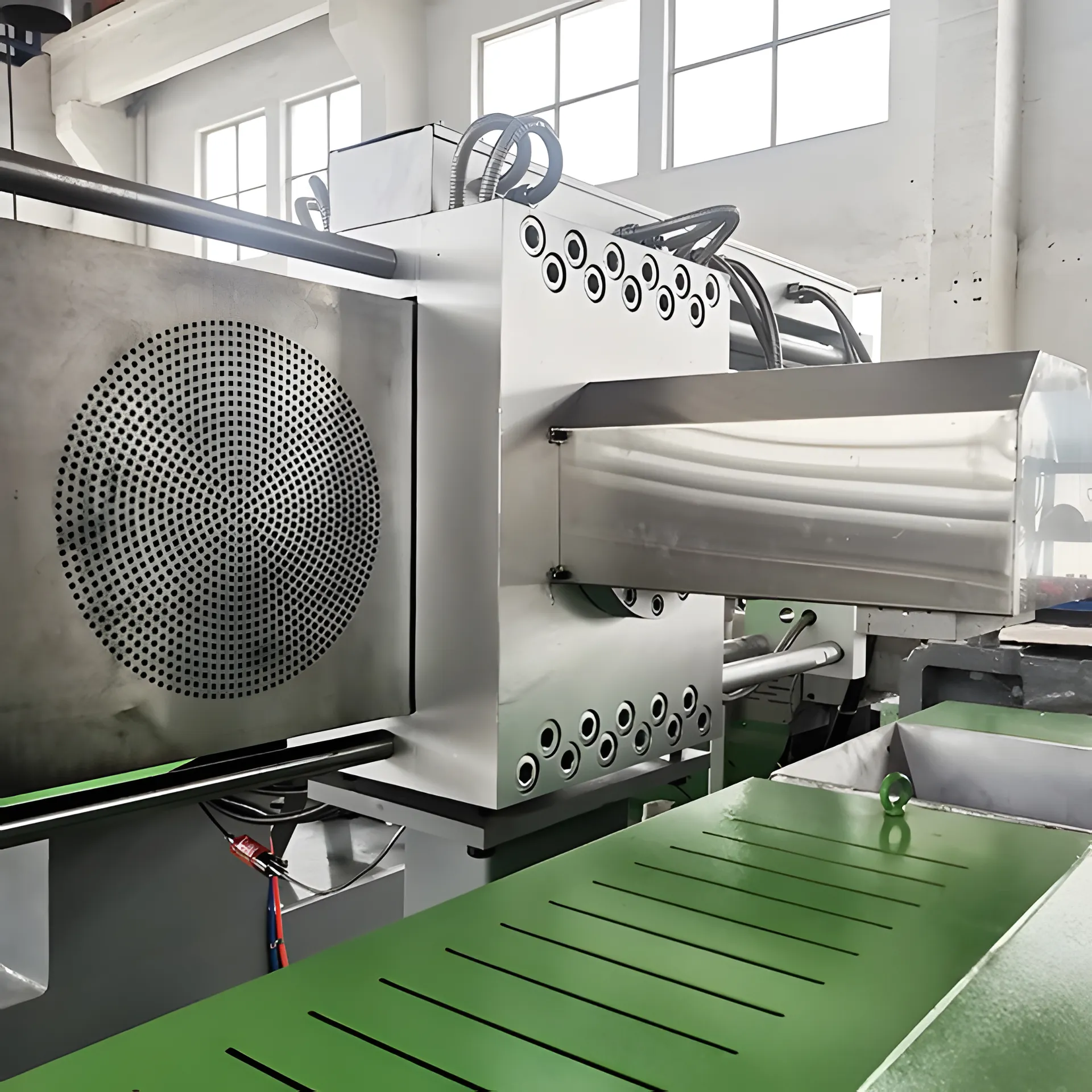

Equipment Photos

Warranty & Service

Get clear warranty terms and responsive after-sales support for your cutter compactor pelletizer line. Share your project requirements and we’ll confirm the right configuration, spare parts plan, and service scope.

Standard Warranty

Typically 12 months for major non-wear components (final terms per contract and model).

Remote Technical Support

Fast troubleshooting guidance via video calls, manuals, and parameter checklists.

Spare Parts Plan

Recommended wear parts and critical spares to reduce downtime and keep output stable.

Installation & Training

Guidance for commissioning, operator training, and maintenance routines for long-term reliability.

Need warranty details for your material and output target? Send an inquiry.

Technical FAQs

Quick answers to common technical questions buyers ask before choosing a cutter compactor pelletizer line.

What is a cutter compactor pelletizer?

A cutter compactor pelletizer combines a cutter-compactor (densifying chamber) with an extruder. The cutter-compactor chops, mixes, and compacts loose film into a dense, free-flowing feedstock, enabling stable extrusion, degassing, filtration, and pelletizing.

What materials can this pelletizing line process?

Typical applications include LDPE/LLDPE/HDPE film, PP film, raffia woven bags, edge trims, and lightly printed film waste. Share material photos/videos plus contamination and moisture level for a recommended configuration.

What pelletizing method does it use?

Most cutter compactor pelletizer lines use a water-ring die-face pelletizing system to produce uniform pellets with stable cutting performance at higher outputs.

How does degassing help pellet quality?

Vacuum degassing removes moisture and volatiles (e.g., inks, residual chemicals), reducing bubbles and odor, and helping stabilize melt quality—especially on printed or washed film scrap.

What information should I provide to get an accurate quote?

Please share your material type (PE/PP), form (loose film, rolls, raffia), contamination level, target output (kg/h), and local power standard. We’ll recommend screw size, filtration, and pelletizing configuration and provide a quotation.

Start Your Recycling Project

Contact us today to learn how our Cutter Compactor Recycling Line can transform your plastic waste into valuable resources!

Comments are closed.