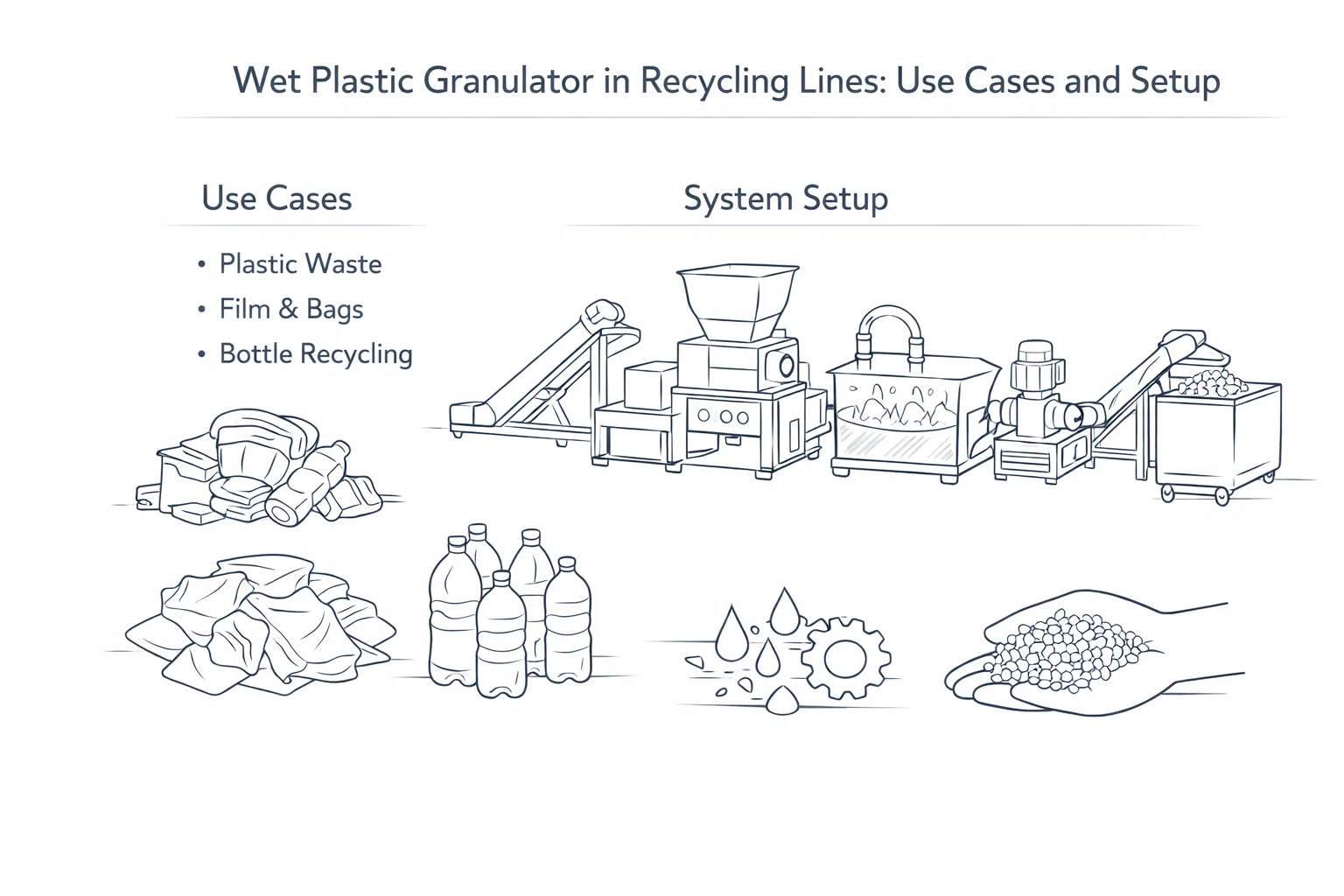

Mit der weltweit steigenden Nachfrage nach recycelten Kunststoffen werden effiziente Verarbeitungstechnologien unerlässlich. Nasskunststoff Granulator Maschinen sind das Herzstück moderner Recyclinganlagen, da sie kontaminierte Kunststoffabfälle in einem einzigen, effizienten Arbeitsgang zerkleinern, quetschen und waschen können. Dieser Leitfaden erklärt die Funktionsweise der Nassgranulation, hebt ihre Vorteile gegenüber der Trockenaufbereitung hervor und stellt die wichtigsten Merkmale unserer Nassgranulatorsysteme für Kunststoffe vor.

Warum einen Nasskunststoffgranulator verwenden?

Die konventionelle Trockengranulierung zersetzt zwar Kunststoffabfälle, kann aber Oberflächenverunreinigungen wie Etiketten, Schmutz und Rückstände nicht entfernen. Nassgranulatoren führen Wasser in die Schneidkammer ein, wodurch die Maschine Folgendes leisten kann:

-

Zerkleinern Sie Plastikmüll in kleinere Flocken und spülen Sie gleichzeitig Schmutz und Etiketten ab.

-

Minimierung der Staubentwicklung und Verbesserung der Luftqualität stromabwärts

-

Reibung und Wärmeentwicklung werden reduziert, wodurch das Material vor thermischer Zersetzung geschützt wird.

-

Sauberere, waschfertige Flocken für eine verbesserte Recyclingeffizienz liefern.

Durch diese Kombination eignet sich die Nassgranulation ideal für die Verarbeitung von Post-Consumer-Kunststoffen wie Flaschen, Folien und starren Behältern.

Wie funktionieren Nasskunststoffgranulatoren?

Nassgranulatoren kombinieren einen leistungsstarken Rotor und stationäre Schaufeln mit einem kontinuierlichen Wassersprühnebel. Im Betrieb:

-

Zuführung & VorzerkleinerungKontaminierte Kunststoffe gelangen in den Trichter und werden vom Rotor erfasst.

-

Hochgeschwindigkeitsschneiden und -waschenDer Rotor dreht sich mit hoher Geschwindigkeit und schert das Material an feststehenden Klingen ab. Wasser spült die Schneidkammer durch und entfernt dabei Verunreinigungen.

-

NassabflussDie gereinigten Flocken werden über eine Nassförderschnecke oder ein Förderband zur weiteren Wäsche oder Trocknung abgeführt.

-

WasserwiederverwendungDas Prozesswasser kann gefiltert und wiederverwendet werden, um den Wasserverbrauch zu reduzieren.

Richtig konstruierte Nassgranulatoren gewährleisten einen kontinuierlichen Durchsatz bei minimalen Verstopfungen und reduziertem Verschleiß.

Wichtige Merkmale, auf die Sie bei Nasskunststoffgranulatoren achten sollten

Nasskunststoffgranulatoren sollten hinsichtlich Langlebigkeit, Energieverbrauch und Wartungszugänglichkeit bewertet werden. Zu den wichtigsten Konstruktionsmerkmalen gehören typischerweise:

-

Hochgeschwindigkeitsrotorstabilität: Ein ausgewuchteter Rotor sorgt für gleichmäßiges Schneiden und reduziert vibrationsbedingten Verschleiß.

-

Effektive Nassableitung: Eine Förderschnecke oder ein Förderband, das die Flocken schnell entfernt und gleichzeitig freies Wasser ableitet, trägt zur Stabilisierung der nachfolgenden Förderprozesse bei.

-

Ausreichende Motor- und Drehmomentreserve: Ausreichende Leistung verhindert einen Geschwindigkeitsabfall bei härteren Kunststoffen und verbessert die Durchsatzstabilität.

-

Schutzausrüstung in Nassbereichen tragen: Werkstoffe und Dichtungen, die für den dauerhaften Kontakt mit Wasser ausgelegt sind, reduzieren Korrosion und vorzeitigen Lagerausfall.

Anwendungen und kompatible Materialien

Nassgranulatoren sind vielseitig und können eine breite Palette von Kunststoffabfällen verarbeiten, darunter:

-

HDPE-Flaschen und -Behälter

-

PP-Kisten und -Verschlüsse

-

LDPE/LLDPE-Folie und Agrarfolie

-

PET-Flaschen (Vorwäsche)

-

Gemischte starre Kunststoffe mit Etiketten oder Schmutz

Durch die Einbeziehung von Wasser in den Schneideprozess liefern diese Maschinen sauberere Flocken, wodurch die Belastung der nachfolgenden Wasch- und Trennstufen reduziert wird.

Wartungstipps für einen zuverlässigen Betrieb

Damit Ihr Nasskunststoffgranulator reibungslos läuft, beachten Sie bitte folgende bewährte Vorgehensweisen:

-

Rotor- und MesserinspektionÜberprüfen Sie regelmäßig die Schärfe und den Abstand der Klingen; ersetzen oder justieren Sie diese gegebenenfalls.

-

Instandhaltung des Wassersystems: Filter und Sprühdüsen reinigen, um einen gleichmäßigen Durchfluss und Druck zu gewährleisten.

-

LagerschmierungUm vorzeitigen Verschleiß zu vermeiden, halten Sie sich an den empfohlenen Schmierplan.

-

Bildschirmreinigung: Stellen Sie sicher, dass die Entladungssiebe frei von Verstopfungen bleiben, um Überhitzung und Leistungsreduzierung zu vermeiden.

-

Kupplung und Motor prüfen: Überprüfen Sie die Ausrichtung der Kupplung und die Motortemperatur, um Schäden zu vermeiden.

Durch ordnungsgemäße Wartung wird die Lebensdauer der Maschine verlängert, Ausfallzeiten werden reduziert und eine gleichbleibende Ausgabequalität sichergestellt.

Auswahlkriterien für Lieferanten von Nasskunststoffgranulatoren

Bei der Auswahl eines Lieferanten sollten Sie der Betriebssicherheit und der Unterstützung über den gesamten Lebenszyklus Priorität einräumen:

-

Konfiguration passt: Die Möglichkeit, Messerkonfiguration, Auswurfart und Durchsatz an Ihr Material und Ihre Anordnung anzupassen.

-

Dokumentierte Referenzen: Nachweis ähnlicher Anlagen und Rohstoffbedingungen.

-

Bereitschaft zur Ersatzteilversorgung: Klare Lieferzeiten und empfohlene Liste kritischer Ersatzteile (Messer, Siebe, Lager, Dichtungen).

-

Serviceantwort: Unterstützung bei der Inbetriebnahme, Fehlerbehebung und Wartungshinweise.

-

Kommerzielle Klarheit: Transparenter Anwendungsbereich, Annahmen bezüglich der Versorgungseinrichtungen (Wasserrückführung) und Leistungserwartungen.

Checkliste für die Einrichtung: Integration eines Nasskunststoffgranulators in eine Recyclinglinie

Nutzen Sie diese Checkliste, um Engpässe und unnötigen Verschleiß bei der Inbetriebnahme eines Nassgranulators zu vermeiden:

-

Platzierung in der Reihe: Typischerweise erfolgt dies nach der manuellen Sortierung und vor der Schwimm-Sink-Trennung oder der Reibungswäsche, sodass der Granulator eine erste Größenreduzierung und eine Oberflächenspülung durchführt.

-

Wassersprühung und -umwälzung: Sorgen Sie für eine gleichmäßige Sprühverteilung in der Schneidkammer; fügen Sie vor der Rezirkulation eine Filtration (Sieb/Absetzvorrichtung) hinzu, um zu verhindern, dass abrasive Feststoffe den Messerverschleiß beschleunigen.

-

Entsorgungsabwicklung: Prüfen Sie, ob Sie eine Nassförderschnecke oder ein Förderband verwenden werden, und stimmen Sie die nachgelagerten Anlagen (Reibungswäscher, Entwässerungsanlage oder Zentrifugaltrockner) auf die Durchflussrate der Nassflocken ab.

-

Ausrichtung des Ziels: Die Sieb-/Perforationseinstellung richtet sich nach den nachfolgenden Waschprozessen und den Spezifikationen der Käuferflocken; eine zu feine Siebgröße erhöht den Feinanteil und die Belastung der Wasseraufbereitung.

-

Zustandsprüfung und Spaltprüfung des Messers: Legen Sie eine Routine zur Überprüfung der Klingenschärfe und des Messerspalts fest, bevor der Durchsatz erhöht wird.

-

Inbetriebnahmeprüfung: Führen Sie einen kurzen Testlauf mit Ihrem ungünstigsten Ausgangsmaterial (Etiketten, Schmutz, Feuchtigkeitsschwankungen) durch und überprüfen Sie die Ausschussströme und die Wasserklarheit, um die Einstellungen zu validieren.

Bereit, mehr zu erfahren?

Wenn Sie Ihre Recyclinganlage modernisieren oder ein neues Projekt starten möchten, ist es unerlässlich, die Rolle der Nassgranulation zu verstehen. Detaillierte Spezifikationen und Preisinformationen finden Sie hier:, Hier finden Sie Details zu unserem Nasskunststoffgranulator.. Unser Team berät Sie gerne hinsichtlich der passenden Konfiguration für Ihre Bedürfnisse.