Linea di lavaggio e pellettizzazione del macinato PP/PE

Converti la pellicola PP/PE contaminata e rimacinala in pellet di alta qualità con un processo pulito ed efficiente dal punto di vista energetico, progettato per una produzione costante e un basso livello di umidità.

Perché scegliere questa linea

Pellet puliti, produttività stabile e configurazioni flessibili adatte ai vostri materiali e alla vostra scala.

Output ad alta purezza

Un lavaggio e una separazione meticolosi garantiscono pellet puliti, adatti anche alle applicazioni più impegnative.

Efficienza energetica

I moduli ottimizzati e la disposizione intelligente riducono il consumo energetico e le spese operative.

Modulare e Personalizzabile

Configurare in base ai livelli di contaminazione, ai vincoli di spazio e alla capacità target.

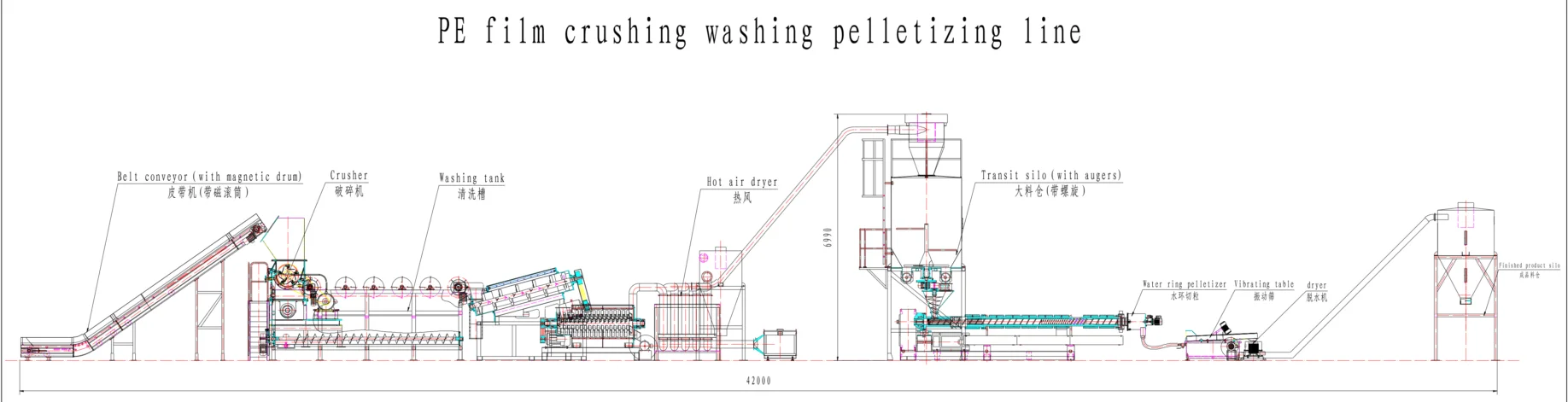

Da rifiuto a valore: flusso di processo

Input e riduzione pre-dimensionata

Pellicola PP/PE triturata e macinata preparata in dimensioni stabili e trasportabili.

Lavaggio intensivo

La pulizia a frizione rimuove rapidamente etichette, carta e contaminanti superficiali.

Separazione affondamento/galleggiamento

La separazione per densità espelle le impurità più pesanti, trattenendo al contempo la pellicola PP/PE.

Essiccazione meccanica e termica

La disidratazione centrifuga o la spremitura + tubi ad aria calda raggiungono un'umidità ≤ 3–5%.

Pellettizzazione

Il sistema ad anello d'acqua scioglie, filtra e taglia in pellet rotondi pronti per il riutilizzo.

Applicazioni

Imballaggi flessibili

Pellicola estensibile LDPE/LLDPE post-consumo, pellicola termoretraibile e rifiuti di imballaggi commerciali.

Film agricolo

Pellicola pacciamante, pellicola per serre e tubi di irrigazione molto sporchi (richiedono una pre-triturazione e la rimozione delle pietre).

Borse intrecciate e jumbo

Rafia PP, FIBC (sacchi jumbo), sacchi intrecciati per cemento/fertilizzante con elevata resistenza alla trazione.

PP/PE Rigido Rimacinato

Parti, tubi, bottiglie e casse stampate a iniezione/soffiaggio difettose, frantumate in scaglie di macinato.

rottami post-industriali

Ritagli di produzione puliti o leggermente stampati, rifili e rotoli difettosi provenienti dalla produzione di pellicole.

Componenti chiave della linea

- Macchina trituratrice di plasticaIl trituratore monoalbero pretaglia la pellicola per evitare grovigli e intasamenti.

- Granulatore di plastica (macinazione a umido)Riduzione delle dimensioni a ~10–20 mm con lavaggio con acqua per il prelavaggio.

- Rondella di attritoLa pulizia ad alta velocità (≈1000 giri/min) rimuove lo sporco incrostato, le etichette e le fibre di carta.

- Serbatoio di separazione lavandino/galleggianteSeparazione della densità mediante acqua per lo scarico di pietre, metalli e sabbia.

- Disidratazione centrifugaSepara l'acqua superficiale per ridurre il consumo di energia prima dell'essiccazione termica.

- Disidratazione con pressa a vite (opzionale)In alcune configurazioni, la spremitura ad alta pressione può sostituire sia la fase centrifuga che quella termica.

- Essiccatore termico e cicloneL'essiccazione tramite tubi ad aria calda e il raffreddamento tramite ciclone rimuovono l'umidità residua e le particelle fini.

- Silo di prodottoTampone di fiocchi puliti e asciutti per un'alimentazione stabile del pelletizzatore.

- Macchina per la pellettizzazione della plasticaIl pelletizzatore ad anello d'acqua fonde, filtra e taglia in pellet uniformi e di alta qualità.

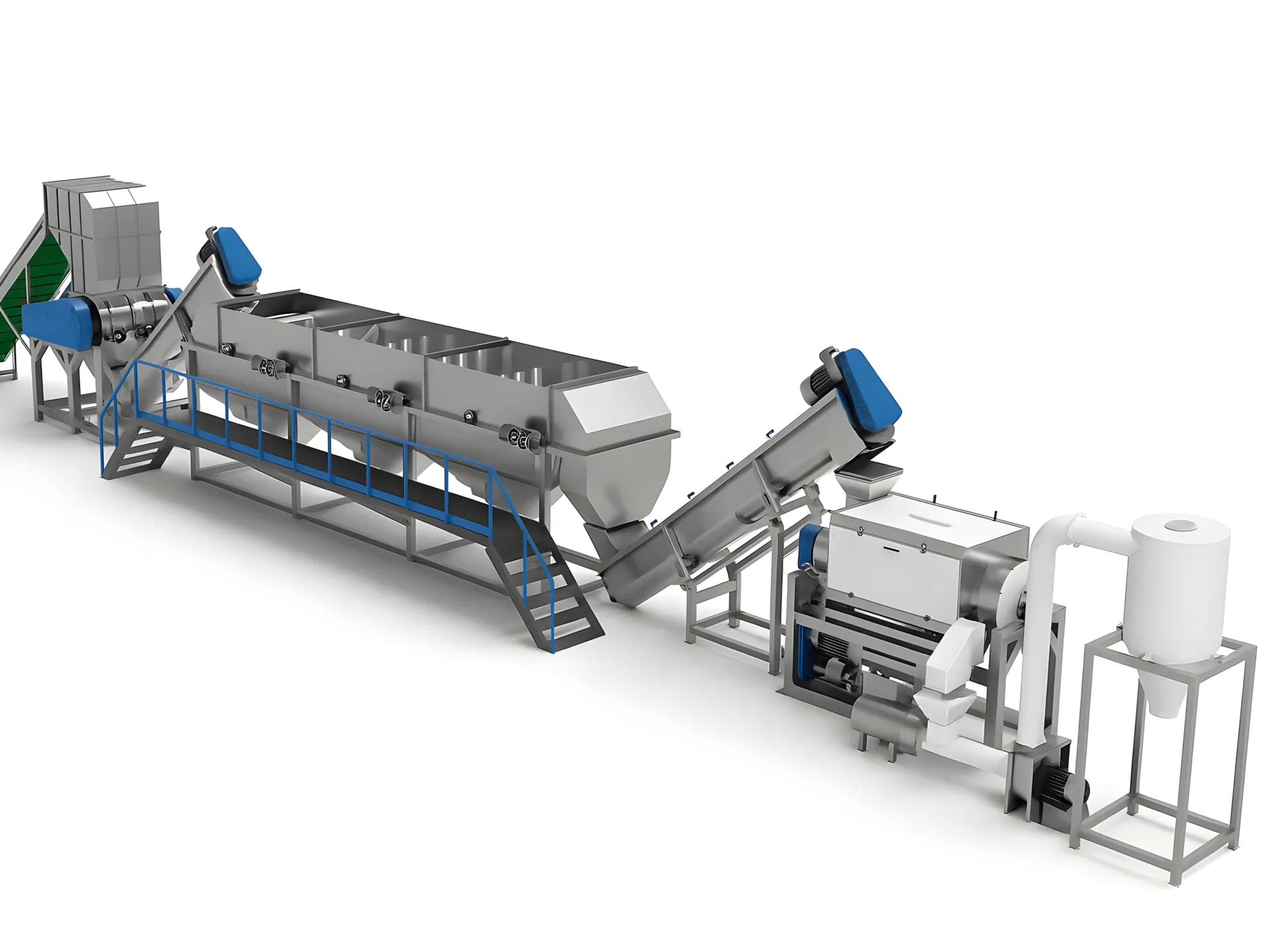

Disposizione tipica

Una soluzione compatta e modulare adatta a linee da 300–2000 kg/h con percorsi di aggiornamento.

Richiedi un preventivo

Condividi i tuoi materiali di input, il livello di contaminazione e la produttività desiderata. Ti proporremo una configurazione e un layout personalizzati.

Domande frequenti

Quali capacità sono disponibili?

Le configurazioni standard coprono portate da 300 a 2000 kg/h. Adattiamo i moduli di linea in base al mix di materiali, alla contaminazione e al personale, per ottenere una produttività costante.

Potenza e conformità per UE/USA?

Le configurazioni UE utilizzano in genere 400 V/50 Hz, USA 460 V/60 Hz (altre su richiesta). Le macchine sono conformi ai requisiti CE; sono disponibili componenti certificati UL e HMI in inglese.

Utilizzo e riciclo dell'acqua?

I sistemi idrici a circuito chiuso con filtrazione riducono al minimo i consumi e gli scarichi. Possiamo integrare il trattamento DAF e la gestione dei fanghi per soddisfare le normative locali.

Installazione, messa in servizio e formazione?

Forniamo disegni di layout, messa in servizio da remoto/in loco e formazione degli operatori. L'installazione richiede in genere dalle 2 alle 4 settimane, a seconda delle dimensioni della linea.

Tempi di consegna e spedizione?

I tempi di consegna sono solitamente di 6-12 settimane franco fabbrica, a seconda della configurazione. Offriamo spedizioni FOB/CIF e organizziamo imballaggi adatti al trasporto via mare.

I commenti sono chiusi.