In der sich ständig weiterentwickelnden Welt des industriellen Recyclings ist das Verständnis der Grundprinzipien hinter Maschinen entscheidend für die Auswahl der richtigen Ausrüstung für Ihren Betrieb. Ein solches Gerät ist die EPS-Kaltpressmaschine – ein wichtiges Werkzeug für das effiziente Recycling von expandiertem Polystyrol (EPS). EPS wird häufig in Verpackungen und im Bauwesen verwendet, seine Entsorgung stellt jedoch aufgrund seines geringen Gewichts und seines Volumens eine erhebliche Umweltbelastung dar. Die EPS-Kaltpressmaschine bietet eine nachhaltige Lösung durch Verdichten und Recycling dieses Materials in eine besser handhabbare Form.

Dieser Artikel bietet eine detaillierte Erklärung zur Funktionsweise der EPS-Kaltpressmaschine und untersucht ihre Funktionen, Anwendungen und Vorteile für industrielle Recyclingvorgänge.

Was ist eine EPS-Kaltpressmaschine?

Ein EPS-Kaltpressmaschine ist eine Recyclingmaschine, die speziell zum Komprimieren und Recyceln von EPS-Schaumstoffabfällen entwickelt wurde. Sie nutzt ein mechanisches Pressverfahren, das ohne Wärmezufuhr auskommt und dadurch im Vergleich zu anderen Verfahren energieeffizienter und umweltfreundlicher ist. Das Verfahren trägt dazu bei, das Volumen von EPS-Schaumstoffabfällen zu reduzieren und diese in eine kompakte Form zu bringen, die entweder in der Produktion wiederverwendet oder zu anderen Produkten weiterverarbeitet werden kann.

Hauptmerkmale:

- Kaltpresstechnologie: Verwendet Druck statt Hitze, um EPS-Schaum zu komprimieren.

- Energieeffizient: Verbraucht weniger Energie im Vergleich zu thermischen Methoden.

- Kompakt und robust: Effiziente Handhabung großer Mengen EPS-Abfall.

Weitere Informationen dazu, wie diese Maschinen Ihren EPS-Recyclingprozess optimieren können, finden Sie auf unserer EPS-Schaum-Kaltpressmaschine Seite.

Das Funktionsprinzip der EPS-Kaltpressmaschine

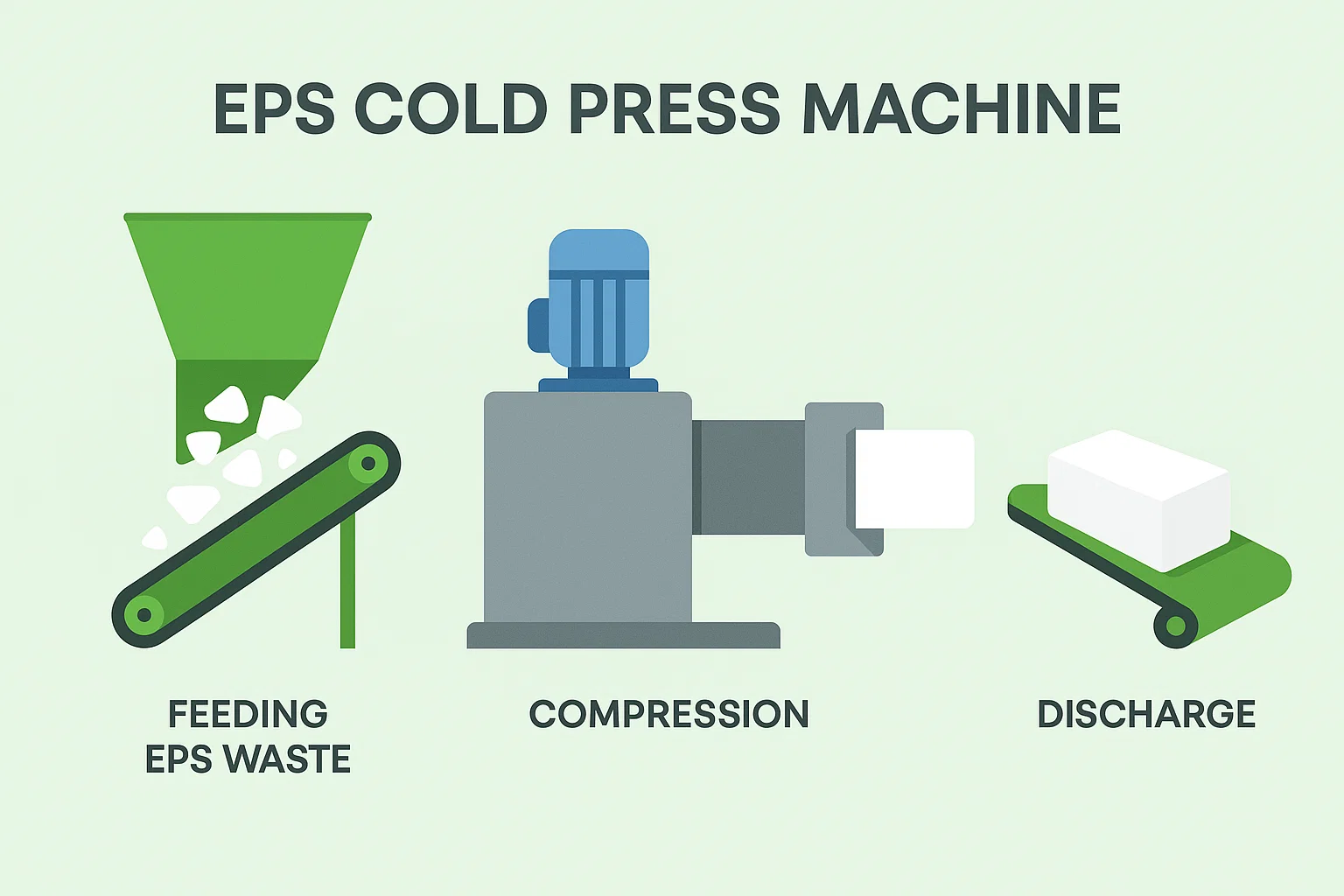

Das Funktionsprinzip einer EPS-Kaltpressmaschine beruht auf ihrer einfachen, aber effektiven Bedienung. Um den Prozess besser zu verstehen, gliedern wir ihn in die wichtigsten Schritte:

1. Zuführung des EPS-Schaumabfalls

Der Prozess beginnt mit der Zufuhr des EPS-Schaumabfalls in die Maschine. Dies kann eine breite Palette von EPS-Produkten umfassen, wie z. B. Verpackungsmaterial, Dämmstoffe und Bauschutt. Der Schaum wird typischerweise in kleinere Stücke oder Brocken zerkleinert, damit er in den Einfülltrichter der Maschine passt.

2. Komprimierungsprozess

Sobald der Schaum in den Trichter gefüllt ist, gelangt er in die Presskammer, wo der Hauptprozess stattfindet. Der EPS-Schaum wird durch ein mechanisches Presssystem hohem Druck ausgesetzt. Dabei wird der Schaum verdichtet und die Luft im Material herausgedrückt, wodurch sein Volumen deutlich reduziert wird.

Das Hydrauliksystem der Maschine sorgt für einen konstanten Druck und kann je nach den spezifischen Anforderungen der Schaumart und des Schaumvolumens angepasst werden.

3. Formen und Gestalten

Nach der Kompression wird das EPS-Material häufig zu kompakten Blöcken oder Ballen geformt. Diese Blöcke lassen sich leichter handhaben, lagern und transportieren und sind daher deutlich effizienter für Recycling und Wiederverwendung. Die verdichteten Blöcke haben zudem eine reduzierte Oberfläche, was sie bei der Entsorgung oder Weiterverarbeitung umweltfreundlicher macht.

4. Entladung

Sobald der EPS-Schaum zu Blöcken oder Ballen verdichtet ist, wird er aus der Maschine ausgetragen. Diese komprimierten EPS-Formen sind dann bereit für die Weiterverarbeitung, beispielsweise für die Herstellung neuer Produkte oder für fortschrittlichere Recyclingverfahren.

Vorteile der Verwendung von EPS-Kaltpressmaschinen

Der EPS-Kaltpressmaschine bietet eine Reihe von Vorteilen und ist daher ein wertvolles Werkzeug für Branchen, die EPS-Abfälle effizient verwalten möchten:

- Umweltauswirkungen: Durch das Recycling von EPS-Schaum trägt die Maschine dazu bei, den Abfall zu reduzieren, der häufig auf Mülldeponien landet. Das Kaltpressverfahren ist zudem umweltfreundlicher und verbraucht weniger Energie als thermische Verfahren.

- Kostengünstig: In Branchen wie der Verpackungs- und Baubranche fällt schnell EPS-Abfall an. Durch die Komprimierung des Schaumstoffs können Unternehmen den Lagerplatzbedarf reduzieren und so Kosten im Abfallmanagement sparen.

- Verbesserte Recyclingeffizienz: Verdichteter EPS-Schaum lässt sich leichter verarbeiten und in der Produktion wiederverwenden. Dadurch wird der Abfallkreislauf geschlossen und die Nachhaltigkeit gefördert.

- Minimaler Wartungsaufwand: Das Kaltpressverfahren reduziert den Verschleiß der Maschinen im Vergleich zu wärmebasierten Verfahren, was zu geringeren Wartungskosten führt.

Anwendungen von EPS-Kaltpressmaschinen

EPS-Kaltpressen sind vielseitig einsetzbar und können in verschiedenen Branchen eingesetzt werden, die große Mengen an EPS-Abfällen verarbeiten. Zu den wichtigsten Anwendungsgebieten gehören:

- Verpackungsindustrie: EPS wird häufig für Verpackungsmaterialien verwendet, insbesondere für zerbrechliche Güter. Die Kaltpresse komprimiert ausrangierte Verpackungsmaterialien und erleichtert so das Recycling.

- Bauindustrie: EPS wird als Dämmstoff im Bausektor eingesetzt. Die Kaltpresse ermöglicht ein effizientes Recycling von Dämmstoffresten.

- Elektronik: Viele Elektronikprodukte werden mit EPS-Schaum verpackt, um Transportschäden zu vermeiden. Das Recycling dieses Schaums mit einer Kaltpresse reduziert den Abfall und fördert die Kreislaufwirtschaft in der Lieferkette.

Wichtige Überlegungen bei der Auswahl einer EPS-Kaltpressmaschine

Beim Kauf einer EPS-Kaltpressmaschine für Ihren Betrieb sollten Sie mehrere Faktoren berücksichtigen, um sicherzustellen, dass Sie das richtige Modell für Ihre Anforderungen auswählen:

- Maschinenkapazität: Stellen Sie sicher, dass die Maschine das in Ihrer Anlage anfallende EPS-Abfallvolumen bewältigen kann.

- Energieverbrauch: Entscheiden Sie sich für Maschinen mit hoher Effizienz und niedrigem Energieverbrauch, um die Betriebskosten zu senken.

- Haltbarkeit und Wartung: Suchen Sie nach robusten Maschinen, die nur minimalen Wartungsaufwand erfordern und für eine lange Lebensdauer unter Schwerlastbedingungen ausgelegt sind.

- Benutzerfreundlichkeit: Wählen Sie eine Maschine mit benutzerfreundlicher Steuerung und minimaler Betriebskomplexität, um die Produktivität zu steigern.

Abschluss

Der EPS-Kaltpressmaschine ist ein wertvoller Bestandteil des industriellen Recyclings und bietet eine effiziente und umweltfreundliche Lösung für EPS-Schaumstoffabfälle. Wenn Sie das Funktionsprinzip, die Funktionen und die Vorteile verstehen, können Sie eine fundierte Entscheidung bei der Auswahl von Recyclingmaschinen für Ihren Betrieb treffen.

Energycle bietet hochwertige EPS-Kaltpressmaschinen, entwickelt, um Ihre Recyclingprozesse zu optimieren und gleichzeitig hervorragende Leistung und Energieeffizienz zu bieten. Wenn Sie Abfall reduzieren, die Nachhaltigkeit verbessern und Betriebskosten sparen möchten, könnte diese Maschine die perfekte Lösung für Ihr Unternehmen sein.

Weitere Informationen zu unseren EPS-Kaltpressmaschinen finden Sie unter Energycle EPS-Schaum-Kaltpressmaschine.