Das Kraftpaket des Kunststoffrecyclings entschlüsselt: So funktioniert ein Kunststoffgranulator

Im industriellen Kunststoffrecycling sind Effizienz und Präzision entscheidend. Das Herzstück vieler erfolgreicher Recyclingprozesse ist eine robuste und zuverlässige Maschine: die KunststoffgranulatorFür Unternehmen, die ihr Kunststoffabfallmanagement optimieren und Abfälle in wertvolle Ressourcen umwandeln möchten, ist das Verständnis der Funktionsweise dieser wichtigen Geräte der erste Schritt.

Wir bei Energycle sind auf die Bereitstellung erstklassiger Kunststoffrecyclingmaschinen spezialisiert und legen großen Wert darauf, unsere Kunden mit Wissen zu versorgen. Dieser umfassende Leitfaden erklärt Ihnen detailliert die Funktionsweise eines Kunststoffgranulators, seine wichtigsten Komponenten und wie er Ihren Recyclingprozess revolutionieren kann.

Die grundlegende Rolle eines Kunststoffgranulators

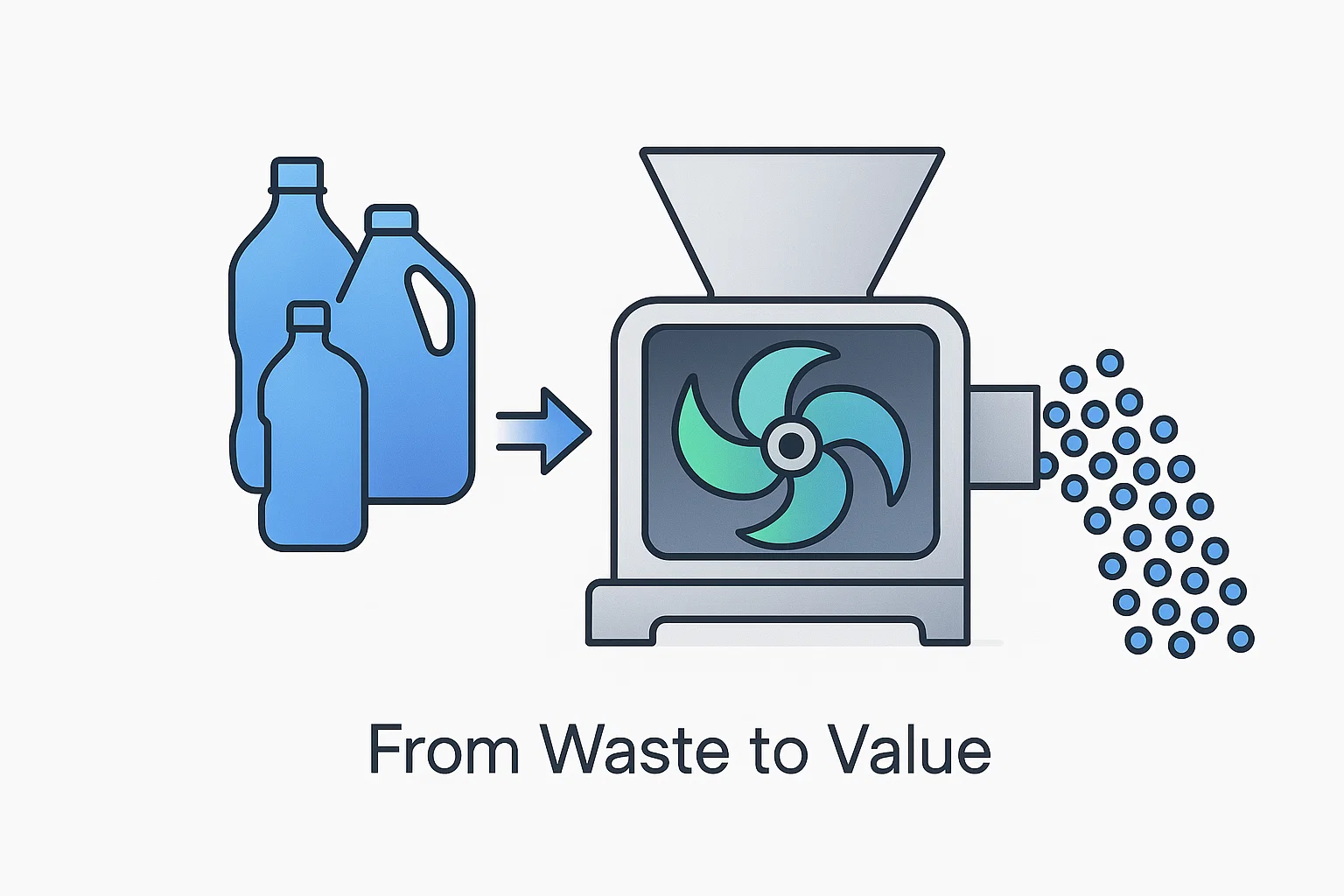

Ein Kunststoffgranulator ist eine leistungsstarke Maschine zur Größenreduzierung. Seine Hauptfunktion besteht darin, große Kunststoffteile – wie Ausschussprodukte, Angüsse, Angusskanäle und andere Industrieabfälle – in kleine, gleichmäßige Partikel, sogenanntes „Mahlgut“, zu zerlegen. Dieser Prozess ist aus mehreren Gründen entscheidend:

- Einfache Handhabung und Transport: Kleinere, gleichmäßige Partikel lassen sich deutlich einfacher lagern und transportieren als sperriger Plastikmüll.

- Vorbereitung zur Weiterverarbeitung: Das von einem Granulator erzeugte Mahlgut kann geschmolzen und zu neuen Kunststoffprodukten verarbeitet werden – ein wichtiger Schritt in der Kreislaufwirtschaft.

- Erhöhter Materialwert: Durch die Umwandlung von minderwertigem Kunststoffabfall in einen wiederverwendbaren Rohstoff steigert ein Granulator den Wert Ihres Abfallstroms erheblich.

Ein Blick ins Innere: Die wichtigsten Komponenten eines Kunststoffgranulators

Die Bauweise kann zwar unterschiedlich sein, die meisten Kunststoffgranulatoren bestehen jedoch aus mehreren Kernkomponenten, die zusammenarbeiten, um eine effiziente Größenreduzierung zu erreichen.

- Der Hopper: Dies ist der Eintrittspunkt für den Kunststoffabfall. Trichter sind für das sichere und einfache Beladen verschiedener Kunststoffarten konzipiert.

- Die Schneidkammer: Hier geschieht die Magie. Die Schneidkammer beherbergt den Rotor und die Messer, die den Kunststoff zerkleinern.

- Der Rotor: Im Zentrum der Schneidkammer befindet sich ein Hochgeschwindigkeitsrotor. Die Konstruktion des Rotors ist ein entscheidender Faktor für die Leistung und Eignung des Granulators für verschiedene Anwendungen.

- Rotierende und stationäre Messer: Am Rotor sind mehrere rotierende Messer montiert, die mit stationären Messern am Kammergehäuse zusammenarbeiten. Der präzise Abstand zwischen diesen Messersätzen erzeugt eine Scherwirkung, die den Kunststoff effizient schneidet.

- Der Bildschirm: Unter der Schneidkammer befindet sich ein Sieb mit präzise dimensionierten Löchern. Dieses Sieb bestimmt die endgültige Größe der Granulatpartikel. Das Material verbleibt in der Schneidkammer, bis es klein genug ist, um das Sieb zu passieren.

- Das Antriebssystem: Ein leistungsstarker Motor treibt den Rotor an. Die Motorleistung ist ein wichtiger Indikator für die Verarbeitungsleistung des Granulators und seine Fähigkeit, auch härtere Materialien zu verarbeiten.

- Das Sammelsystem: Sobald der Kunststoff auf die gewünschte Größe granuliert wurde, wird er aus der Maschine entladen, normalerweise in einen Sammelbehälter oder ein pneumatisches Fördersystem, um zur nächsten Stufe des Recyclingprozesses transportiert zu werden.

Der Granulationsprozess: Ein schrittweiser Arbeitsablauf

Um zu veranschaulichen, wie diese Komponenten zusammenarbeiten, zerlegen wir den Kunststoffgranulierungsprozess in einen einfachen Arbeitsablauf:

Arbeitsablauf eines Kunststoffgranulators

| Schritt | Aktion | Beschreibung |

| 1. Einspeisung | Plastikmüll wird in den Trichter eingefüllt. | Dies kann manuell oder über ein Fördersystem für den Dauerbetrieb erfolgen. |

| 2. Schneiden | Der Hochgeschwindigkeitsrotor und die Messer beginnen, den Kunststoff zu schneiden und zu scheren. | Das Zusammenspiel der rotierenden und stationären Messer sorgt für eine effiziente Zerkleinerung. |

| 3. Größenbestimmung | Der Kunststoff verbleibt in der Schneidkammer, bis er klein genug ist, um durch das Sieb zu passen. | Die Siebgröße wird basierend auf der gewünschten Ausgabepartikelgröße für die jeweilige Anwendung ausgewählt. |

| 4. Entladung | Das nun gleichmäßig große Kunststoffgranulat wird aus der Maschine ausgetragen. | Das Mahlgut wird zur Weiterverarbeitung oder zum Verkauf gesammelt. |

Dieser kontinuierliche Zyklus gewährleistet eine gleichbleibende und zuverlässige Produktion von hochwertigem Kunststoff-Regranulat. Für einen genaueren Blick auf die von uns angebotenen Granulatorentypen, die diesen Prozess bewältigen können, besuchen Sie unsere Seite Kunststoffgranulatoren.

Leistung und Effizienz: Worauf Sie achten sollten

Bei der Betrachtung einer Kunststoffgranulator Für Ihre Einrichtung sind mehrere Leistungsindikatoren entscheidend:

- Durchsatz: Dies bezieht sich auf die Materialmenge, die ein Granulator in einem bestimmten Zeitraum verarbeiten kann (z. B. kg/Stunde oder lbs/Stunde).

- Granulatqualität: Ein hochwertiger Granulator erzeugt gleichmäßige Partikel mit minimalem Staub- oder Feinanteil.

- Energieverbrauch: Moderne Granulatoren sind auf Energieeffizienz ausgelegt und senken so die Betriebskosten.

- Einfache Wartung: Achten Sie auf Funktionen, die einen einfachen Zugang zur Schneidkammer zum Messerwechsel und Reinigen ermöglichen.

Häufig gestellte Fragen (FAQ)

Wir wissen, dass Investitionen in Industriemaschinen viele Fragen aufwerfen. Hier sind einige der häufigsten Anfragen unserer Kunden:

1. Welche Kunststoffarten kann ein Granulator verarbeiten?

Unsere Kunststoffgranulatoren sind für die Verarbeitung einer Vielzahl thermoplastischer Kunststoffe ausgelegt, darunter:

- Polyethylen (PE) – HDPE, LDPE, LLDPE

- Polypropylen (PP)

- Polyvinylchlorid (PVC)

- Polyethylenterephthalat (PET)

- Polystyrol (PS)

- Acrylnitril-Butadien-Styrol (ABS)1

- Und viele andere technische Kunststoffe.

Die Eignung eines bestimmten Granulators hängt von der Härte, Dicke und Form des Materials ab.

2. Was ist der Unterschied zwischen einem Granulator und einem Schredder?

Beide dienen zwar der Größenreduzierung, funktionieren aber unterschiedlich. Ein Aktenvernichter nutzt ein hohes Drehmoment und eine niedrige Drehzahl, um große, sperrige Gegenstände in kleinere, unregelmäßige Stücke zu zerlegen. Ein Kunststoffgranulator, hingegen nutzt hohe Geschwindigkeit und Schneidwirkung, um kleinere, gleichmäßige Partikel zu erzeugen. Oft wird ein Schredder zur Vorverarbeitung eingesetzt, bevor das Material zur endgültigen Größensortierung in einen Granulator gegeben wird.

3. Wie wähle ich die richtige Granulatorgröße für meinen Bedarf aus?

Die richtige Granulatorgröße hängt von mehreren Faktoren ab:

- Art und Menge Ihres Kunststoffabfalls.

- Der erforderliche Durchsatz, um mit Ihrer Produktion Schritt zu halten.

- Die gewünschte endgültige Partikelgröße.

- Die verfügbare Grundfläche in Ihrer Einrichtung.

Unser Team bei Energycle kann Ihnen bei der Bewertung Ihrer spezifischen Anforderungen helfen und Ihnen den perfekten Granulator für Ihre Anwendung empfehlen.

4. Welche Wartungsanforderungen gelten für einen Kunststoffgranulator?

Regelmäßige Wartung ist entscheidend für die Langlebigkeit und optimale Leistung Ihres Granulators. Dazu gehören typischerweise:

- Regelmäßiges Überprüfen und Drehen bzw. Ersetzen der Messer.

- Reinigen des Siebes, um eine gleichmäßige Partikelgröße sicherzustellen.

- Schmieren von Lagern und anderen beweglichen Teilen.

- Überprüfen Sie den Antriebsriemen auf richtige Spannung und Verschleiß.

Wir bieten umfassende Wartungsrichtlinien und Support für alle unsere Maschinen.

5. Kann das Kunststoffgranulat in meiner eigenen Produktion wiederverwendet werden?

Absolut! Dies ist einer der Hauptvorteile eines Kunststoffgranulators. Das hochwertige, gleichmäßige Mahlgut kann oft mit Neuware gemischt und wieder in Ihren Herstellungsprozess eingebracht werden, was zu erheblichen Kosteneinsparungen und einem nachhaltigeren Betrieb führt.

Investieren in eine Kunststoffgranulator aus Energiecle ist eine Investition in die Effizienz, Rentabilität und Nachhaltigkeit Ihres Unternehmens. Wenn Sie die Funktionsweise dieser leistungsstarken Maschine verstehen, können Sie eine fundierte Entscheidung treffen, die Ihrem Betrieb langfristig zugutekommt. Bei weiteren Fragen oder wenn Sie Ihre spezifischen Recyclinganforderungen besprechen möchten, kontaktieren Sie unser Expertenteam noch heute.