Linia do mycia i peletyzacji przemiału PP/PE

Przekształcaj zanieczyszczoną folię PP/PE i przerabiaj ją na wysokiej jakości peletki w czystym, energooszczędnym procesie, który zapewnia stałą wydajność i niską wilgotność.

Dlaczego warto wybrać tę linię

Czyste peletki, stabilna przepustowość i elastyczne konfiguracje dostosowane do Twoich materiałów i skali.

Wysoka czystość wyjścia

Dokładne mycie i separacja pozwalają uzyskać czyste peletki, nadające się do wymagających zastosowań.

Energooszczędny

Zoptymalizowane moduły i przemyślany układ zmniejszają zużycie energii i koszty operacyjne.

Modułowy i konfigurowalny

Skonfiguruj tak, aby odpowiadała poziomowi skażenia, ograniczeniom przestrzennym i docelowej pojemności.

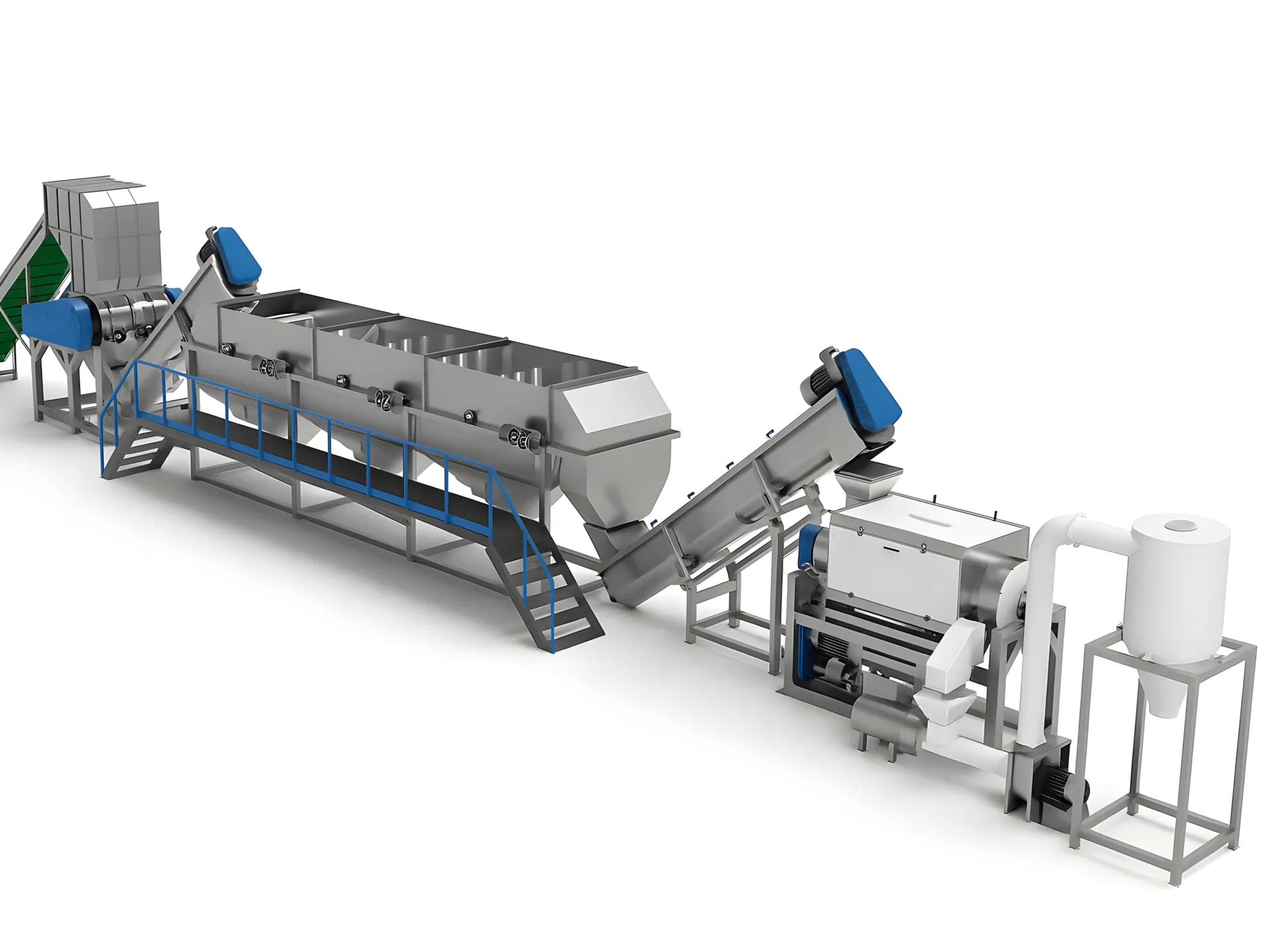

Od odpadów do wartości: Przebieg procesu

Wprowadzanie i redukcja rozmiaru wstępnego

Pocięta folia PP/PE i przemiał przygotowane do stabilnych, transportowych rozmiarów.

Intensywne pranie

Czyszczenie tarciowe pozwala szybko usunąć etykiety, papier i zanieczyszczenia powierzchni.

Separacja tonącego/pływającego

Separacja gęstościowa pozwala na usunięcie dużych zanieczyszczeń, a jednocześnie zachowanie folii PP/PE.

Suszenie mechaniczne i termiczne

Odwadnianie odśrodkowe lub wyciskarka + rury z gorącym powietrzem pozwalają na osiągnięcie wilgotności ≤ 3–5%.

Pelletyzacja

System pierścieni wodnych topi, filtruje i tnie na okrągłe peletki gotowe do ponownego użycia.

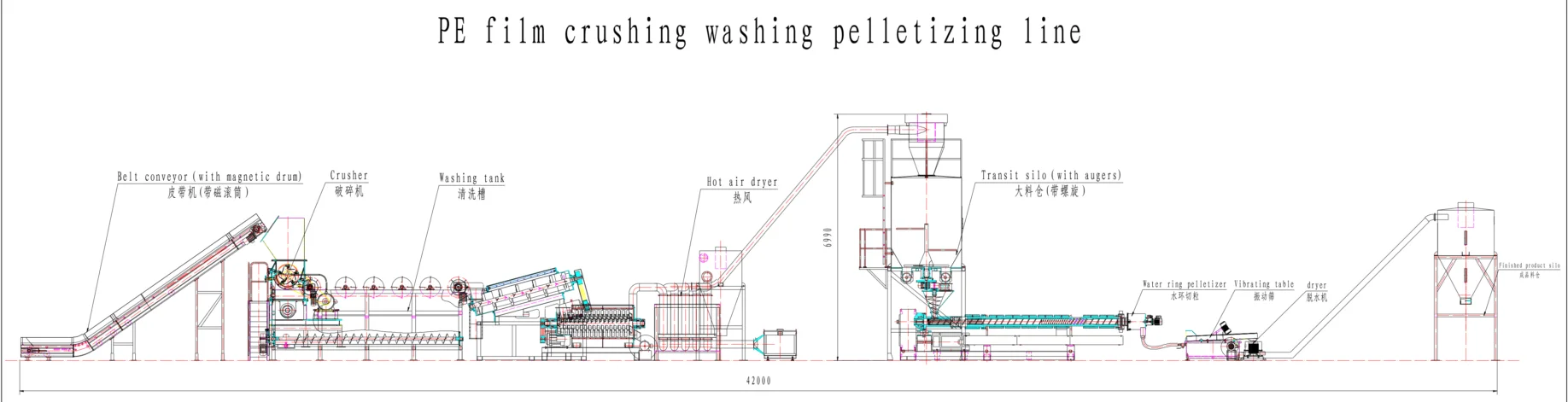

Kluczowe komponenty linii

- Maszyna do rozdrabniania plastikuWytrzymała niszczarka jednowałowa wstępnie tnie folię, zapobiegając jej plątaniu się i zatykaniu.

- Granulator plastiku (mielenie na mokro)Zmniejszenie rozmiaru do ~10–20 mm poprzez płukanie wodą w celu wstępnego mycia.

- Podkładka ciernaSzybkie szorowanie (≈1000 obr./min) usuwa głęboko osadzony brud, etykiety i włókna papieru.

- Zbiornik separacyjny tonący/pływającySeparacja gęstości na bazie wody w celu usuwania kamieni, metali i piasku.

- Odwadnianie odśrodkoweOddziela wodę powierzchniową w celu ograniczenia zużycia energii przed suszeniem termicznym.

- Odwadnianie za pomocą prasy ślimakowej (opcjonalnie)W niektórych konfiguracjach ściskanie pod wysokim ciśnieniem może zastąpić zarówno etap odśrodkowy, jak i termiczny.

- Suszarka termiczna i cyklonSuszenie gorącym powietrzem i chłodzenie cyklonowe usuwają resztkową wilgoć i drobne zanieczyszczenia.

- Silos produktówCzysty, suchy bufor płatków zapewniający stabilne zasilanie granulatora.

- Maszyna do granulacji plastikuGranulator pierścieniowo-wodny topi, filtruje i tnie na jednolite, wysokiej jakości peletki.

Typowy układ

Kompaktowe, modułowe rozwiązanie przeznaczone do linii o wydajności 300–2000 kg/h z możliwością modernizacji.

Poproś o wycenę

Udostępnij swoje materiały wejściowe, poziom zanieczyszczeń i docelową przepustowość. Zaproponujemy dostosowaną konfigurację i układ.

Często zadawane pytania

Jakie pojemności są dostępne?

Standardowe konfiguracje obejmują wydajność 300–2000 kg/h. Dostosowujemy moduły linii do Państwa składu materiałowego, stopnia zanieczyszczenia i obsady, aby zapewnić stabilną przepustowość.

Moc i zgodność dla UE/USA?

W konfiguracjach EU zazwyczaj stosuje się napięcie 400 V/50 Hz, US 460 V/60 Hz (inne na życzenie). Maszyny spełniają wymagania CE; dostępne są komponenty z certyfikatem UL oraz interfejs HMI w wersji angielskiej.

Zużycie wody i recykling?

Zamknięte systemy wodne z filtracją minimalizują zużycie i zrzut wody. Możemy zintegrować system DAF i system odprowadzania osadów, aby spełnić lokalne przepisy.

Instalacja, uruchomienie i szkolenie?

Oferujemy rysunki techniczne, zdalne/na miejscu uruchomienie oraz szkolenie operatorów. Typowy czas instalacji wynosi od 2 do 4 tygodni, w zależności od rozmiaru linii.

Czas realizacji i wysyłka?

Czas realizacji zamówienia wynosi zazwyczaj od 6 do 12 tygodni ex-works, w zależności od konfiguracji. Obsługujemy warunki FOB/CIF i organizujemy skrzynie dostosowane do transportu morskiego.

Komentarze są zamknięte.