Przewodnik techniczny · Wybór materiału ostrza

SKD-11 vs D2 vs DC53 vs 55SiCr: najlepsza stal na ostrza do niszczarek do plastiku

Wybór materiału ostrza ma bezpośredni wpływ na wydajność cięcia, żywotność, zużycie energii i przestoje w recyklingu tworzyw sztucznych. W tym przewodniku porównano cztery powszechnie stosowane stale na ostrza – SKD-11 (ekwiwalent D2), D2, DC53 i 55SiCr – aby pomóc Ci dobrać odpowiedni materiał do rodzaju tworzywa, poziomu zanieczyszczenia i warunków pracy.

Dlaczego materiał ostrza ma znaczenie

W rozdrabniaczach i kruszarkach do tworzyw sztucznych ostrza są narażone na ciągłe ścieranie, obciążenia udarowe, nagrzewanie i sporadyczne zanieczyszczenie metalem. Wybór niewłaściwego gatunku stali zazwyczaj skutkuje szybkim zużyciem krawędzi, odpryskami, częstym ostrzeniem, niestabilną wielkością cząstek i rosnącym poborem mocy. Wybór odpowiedniego gatunku stali wydłuża czas sprawności i obniża całkowity koszt przetworzonej tony.

Praktyczna zasada: Tworzywa sztuczne o wysokiej odporności na ścieranie wymagają większej odporności na zużycie. Strumienie o dużej odporności na uderzenia lub zanieczyszczone wymagają wyższej wytrzymałości.

Szybkie rekomendacje

Najlepszy do materiałów ściernych

D2 / SKD-11 zapewnia długą żywotność w przypadku sztywnych tworzyw sztucznych i strumieni ściernych (np. tworzyw sztucznych z wypełniaczami, zanieczyszczonych przemiałów).

Najlepsza równowaga (zużycie + wytrzymałość)

DC53 gdy potrzebna jest zarówno odporność na zużycie, jak i udarność (tworzywa sztuczne mieszane, PVC, materiały gumowe/zmienne podawanie).

Najlepiej sprawdza się w przypadku obciążeń udarowych/uderzeniowych

55SiCr do warunków, w których występują nagłe uderzenia, wibracje lub częste występowanie twardych inkluzji — często stosowane tam, gdzie priorytetem jest wytrzymałość.

Najlepszy punkt wyjścia

Jeśli nie masz pewności, zacznij od DC53 w przypadku strumieni mieszanych należy zoptymalizować dane dotyczące zużycia i odstępy między ostrzeniami.

Ostateczna wydajność zależy również od geometrii ostrza, obróbki cieplnej, luzu, prędkości wirnika oraz od tego, czy maszyna jest rozdrabniaczem, czy kruszarką. Wytrzymała stal nie zrekompensuje nieprawidłowego ustawienia cięcia.

Tabela porównawcza materiałów

| Gatunek stali | Odporność na zużycie | Wytrzymałość | Najlepsze przypadki użycia | Typowe tworzywa sztuczne |

|---|---|---|---|---|

| SKD-11 (rodzina D2) | Bardzo wysoki | Średni | Długi czas pracy, stabilna krawędź tnąca | ABS, PS, PA/nylon, sztywny regranulat |

| D2 | Bardzo wysoki | Średni | Materiały ścierne/brudzące, tworzywa sztuczne wypełnione | Tworzywa sztuczne wypełnione GF, mieszane sztywne, wytrzymałe przemiały |

| DC53 | Wysoki | Wysoki | Najlepsza równowaga dla zmiennego surowca | PVC, tworzywa sztuczne mieszane, guma, strumienie niespójne |

| 55SiCr | Średni | Bardzo wysoki | Warunki silnego uderzenia, obciążenia udarowe | Miększe tworzywa sztuczne, zanieczyszczone strumienie z powodu uderzeń |

Notatka: “Najlepszy” wynik zależy od rodzaju odpadów. Ostrze, które najdłużej wytrzymuje na czystych, sztywnych tworzywach sztucznych, może się odłupywać na silnie zmieszanych odpadach.

Profile materiałowe

SKD-11 (często porównywany do D2)

- Wytrzymałość: doskonała odporność na zużycie i stabilne utrzymanie krawędzi.

- Najlepiej dla: długie kampanie na sztywnych tworzywach sztucznych z równomiernym podawaniem.

- Uwaga: może się odpryskiwać, jeśli wsad zawiera częste, twarde uderzenia lub wtrącenia metalowe.

D2

- Wytrzymałość: bardzo wysoka odporność na zużycie, szczególnie w warunkach ściernych.

- Najlepiej dla: materiały ścierne/brudzące i tworzywa sztuczne z wypełniaczami (np. zawierające włókno szklane).

- Uwaga: średnia wytrzymałość; priorytetem jest odpowiednia kontrola czystości i zanieczyszczeń.

DC53

- Wytrzymałość: doskonała równowaga pomiędzy odpornością na zużycie i wytrzymałością.

- Najlepiej dla: mieszane tworzywa sztuczne, PVC i zmienne surowce, w przypadku których występują uderzenia.

- Uwaga: Wydajność w dużym stopniu zależy od obróbki cieplnej i stabilnej konfiguracji operacyjnej.

55SiCr

- Wytrzymałość: wysoka amortyzacja i wytrzymałość na uderzenia.

- Najlepiej dla: zastosowania, w których głównym powodem uszkodzeń są odpryski.

- Uwaga: zwykle niższa odporność na zużycie; może wymagać częstszego ostrzenia w strumieniach ściernych.

Jak wybrać odpowiednie ostrze

1) Rodzaj i twardość plastiku

Sztywne tworzywa sztuczne i polimery konstrukcyjne często charakteryzują się większą odpornością na zużycie. Miękkie tworzywa sztuczne mogą tolerować niższą twardość, ale wymagają większej odporności na uderzenia.

2) Materiały ścierne i zanieczyszczenia

Włókno szklane, wypełniacze mineralne, piasek/brud i zanieczyszczone strumienie szybko ścierają krawędzie — w zależności od stopnia uderzenia należy stosować D2/SKD-11 lub DC53.

3) Obciążenia udarowe

Twarde wtrącenia i nierównomierne podawanie materiału mogą powodować wykruszanie się ostrzy — należy priorytetowo traktować wytrzymałość (DC53 lub 55SiCr) i zaostrzyć kontrolę zanieczyszczeń.

4) Rozmiar wyjściowy i przepustowość

Wysoka przepustowość zwiększa temperaturę i obciążenie. Upewnij się, że gatunek stali jest odpowiedni do Twojego cyklu pracy i częstotliwości konserwacji.

Podejście praktyczne: Jeśli przetwarzasz tworzywa sztuczne mieszane, wybierz najpierw DC53. Jeśli przetwarzasz tworzywa sztuczne z wypełniaczami ściernymi, wybierz D2/SKD-11. Jeśli dominuje odpryskiwanie, rozważ 55SiCr.

Wskazówki dotyczące wydłużenia żywotności ostrza

- Kontrola skażenia: W miarę możliwości należy usuwać metale i kamienie w górnym biegu rzeki.

- Zachowaj odstęp: nieprawidłowe odstępy między nożami przyspieszają zużycie i zwiększają pobór mocy.

- Stosuj właściwe odstępy czasu między ostrzeniami: nie należy używać ostrzy całkowicie stępionych, gdyż zwiększa to ryzyko narażenia na ciepło i odkształcenie.

- Dopasuj prędkość wirnika do materiału: zbyt szybki wzrost temperatury; zbyt wolny wzrost naprężeń spowodowanych uderzeniem.

- Rejestr danych o zużyciu: śledź tonaż pomiędzy ostrzeniami, aby wybrać najlepszą klasę dla swojego strumienia.

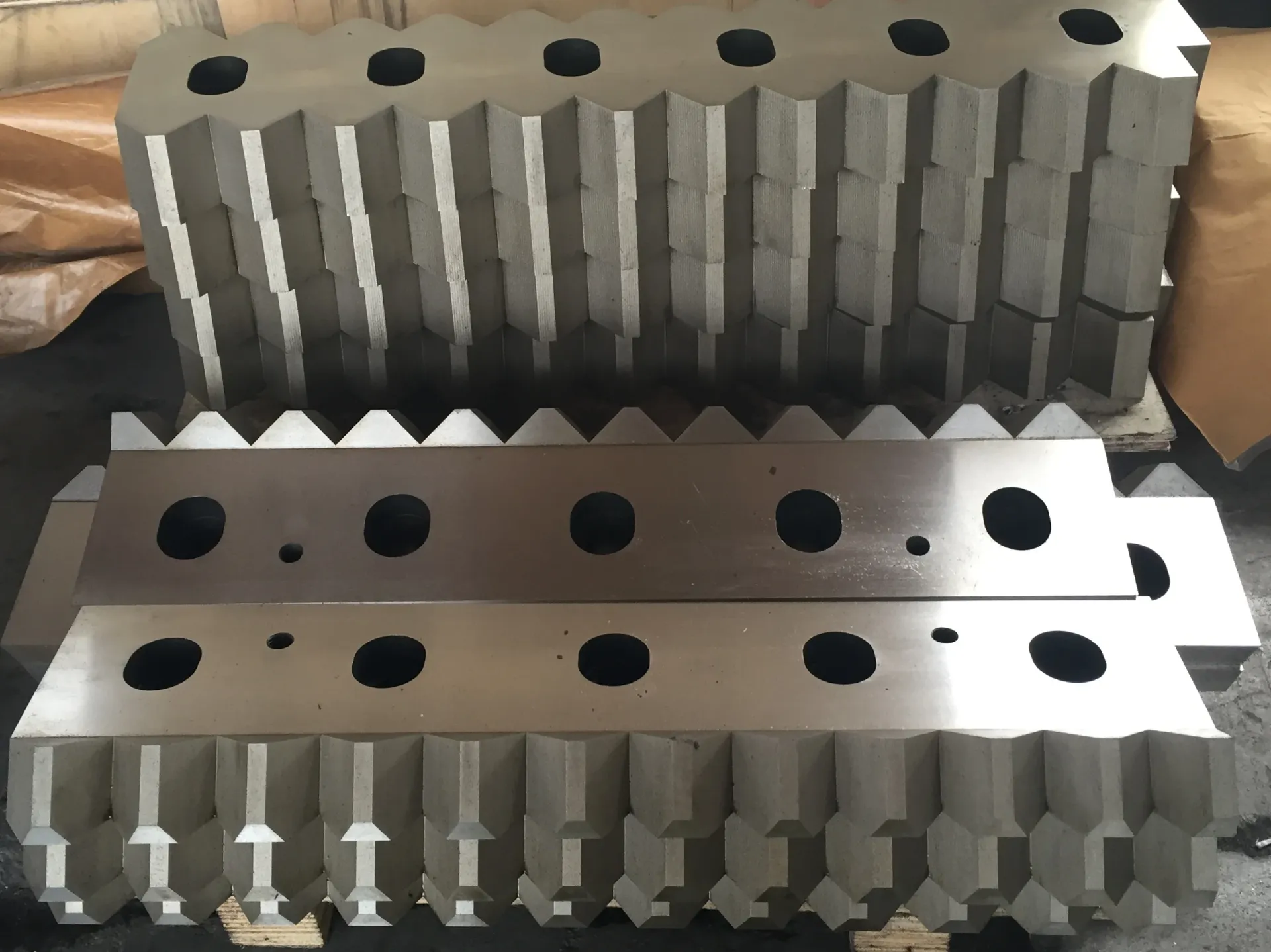

Które niszczarki wykorzystują te ostrza?

Te materiały na ostrza są powszechnie stosowane w rozdrabniaczach jednowałowych, dwuwałowych oraz kruszarkach do tworzyw sztucznych do przetwarzania sztywnych tworzyw sztucznych, folii, worków tkanych, rur i odpadów mieszanych. Wybór najlepszej jakości zależy od zastosowania i konstrukcji maszyny.

Poznaj modele i zastosowania niszczarek do tworzyw sztucznych tutaj: Niszczarki do plastiku.

Często zadawane pytania

Czy SKD-11 to to samo co D2?

Są to blisko spokrewnione stale narzędziowe, często porównywane w przemyśle. Wydajność zależy od obróbki cieplnej, docelowej twardości i geometrii cięcia.

Jaka stal na ostrza jest najlepsza do PVC?

DC53 jest powszechnie wybierany do PVC i strumieni mieszanych, ponieważ zapewnia równowagę między odpornością na zużycie a wytrzymałością w zmiennych warunkach.

Dlaczego ostrza pękają, nawet jeśli są wykonane z “twardej” stali?

Odpryskiwanie jest zwykle spowodowane problemami z wytrzymałością/udarowością: twardymi wtrąceniami, zanieczyszczeniami metalowymi, nieprawidłowym luzem lub nadmiernymi obciążeniami udarowymi.

Porozmawiaj z inżynierem

Wydajność ostrza zależy od rodzaju tworzywa sztucznego, zanieczyszczenia, przepustowości i konfiguracji maszyny. Jeśli udostępnisz zdjęcia materiału, docelową wielkość wyjściową oraz model niszczarki lub kruszarki, zespół Energycle może zalecić najbardziej odpowiednią stal ostrza oraz częstotliwość konserwacji, aby zapewnić ciągłość pracy.

Aby polecić właściwy rodzaj ostrza, prosimy o uwzględnienie:

- Rodzaj plastiku i zdjęcia (czysty vs brudny, wypełniacze, etykiety, ryzyko związane z metalami)

- Docelowa wydajność (kg/h) i liczba godzin pracy/dzień

- Typ maszyny (jednowałowa, dwuwałowa, kruszarka) i model

- Docelowy rozmiar wydruku i ekran (jeśli dotyczy)