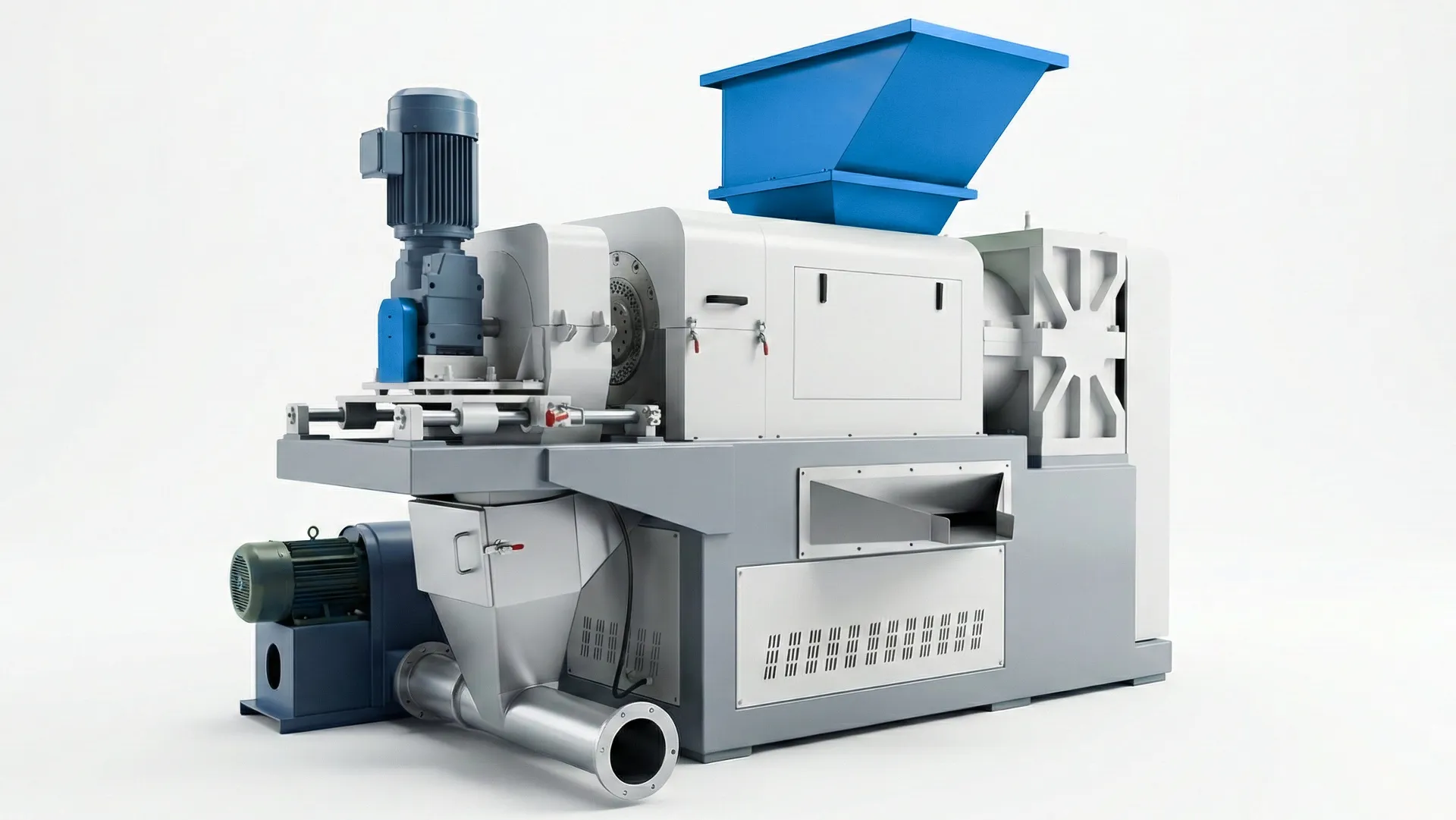

Plastic Film Squeezing and Drying Machine

The ultimate solution for dewatering washed PP/PE films and woven bags. Our squeezer reduces moisture to 1-5%, preparing your material for high-quality pelletizing and boosting your line efficiency.

Get a Custom QuoteMoisture Reduction Challenge

The High Cost of Wet Film

- Washed film holds up to ~40% moisture, making direct pelletizing difficult.

- Traditional dryers are inefficient and still leave 20-30% moisture.

- Wet, fluffy material causes unstable feeding and extruder clogging.

The Squeezer Dryer Solution

- Mechanical pressure squeezes water out efficiently, reaching under 5% moisture.

- Film is densified into compact lumps for consistent extruder feeding.

- Replaces multiple drying steps with one high-performance machine.

Operating Sequence

1. Feeding

Wet washed film or woven bag scrap enters the hopper.

2. Squeezing

A high-torque screw pushes material through a perforated barrel.

3. Dehydration

Water is expelled through perforations down to low residual moisture.

4. Densification

Material is compacted into high-density lumps by frictional heat.

5. Discharge

Output is ready for direct feeding into pelletizing equipment.

Performance Advantages

Efficient Moisture Reduction

Reduces 10-35% moisture down to 1-5% for stable downstream processing.

Density and Volume Optimization

Transforms loose film into dense lumps for faster, consistent feeding.

Minimized Heat and Degradation

Low thermal load preserves polymer quality and pellet value.

Higher Extruder Efficiency

Boosts pelletizing throughput through stable feed behavior.

Improved Pellet Quality

Drier, denser input reduces defects like bubbles and voids.

Extrusion-ready Output

Optimally prepares material for compactor-extruder pelletizing lines.

Line Integration

Washing Line

Squeezer Dryer

Pelletizing Extruder

Video Demonstration

Downstream Applications

High-quality Pellet Production

Densified lumps provide a stable feedstock for premium-grade PE/PP pellets.

Injection Molded Products

Pellets are suitable for pallets, crates, and many industrial molded parts.

New Film and Bag Extrusion

High-quality pellets can be used in new non-food-grade film and bag products.

Technical Specifications

| Model | Screw Diameter (mm) | Applicable Material | Output (kg/h) |

|---|---|---|---|

| ERM-250C | 250 | PP / PE Film and Woven Bags | 200 - 350 |

| ERM-300S | 300 | PP / PE Film and Woven Bags | 400 - 550 |

| ERM-320P | 320 | PP / PE Film and Woven Bags | 600 - 750 |

| ERM-350M | 350 | PP / PE Film and Woven Bags | 800 - 1000 |

Operating Clarifications

What materials can this machine process?

What is the typical final moisture content?

Will squeezing overheat or degrade the plastic?

User Feedback

We replaced our old centrifugal dryer with this squeezer and output increased by nearly 30% because feeding became much more stable.

Pellet quality improved dramatically. We no longer see voids and bubbles caused by excess moisture.

One machine now handles both dewatering and densifying with lower energy use. The ROI was clear from the beginning.

Quote Request

Each squeezer includes a 1-year limited warranty. Factory engineers can support installation, commissioning, and operator training. Contact our specialists for configuration and a detailed quote.