Sink-Float Separation Tank

The cornerstone of any high-performance PET plastic washing line. Our sink-float tank uses the simple principle of water density to achieve over 99% purity, efficiently separating valuable PET flakes from lighter PP/PE contaminants.

Achieve Premium Quality, Automatically

Our sink-float tank is engineered to be the reliable heart of your washing line, delivering consistent results that elevate the value of your final product.

High Purity Separation

Leverages water density to perfectly sink PET flakes (density >1.2 g/cm³) while floating lighter contaminants like PP/PE caps and labels, ensuring premium quality output.

Automated & Continuous Workflow

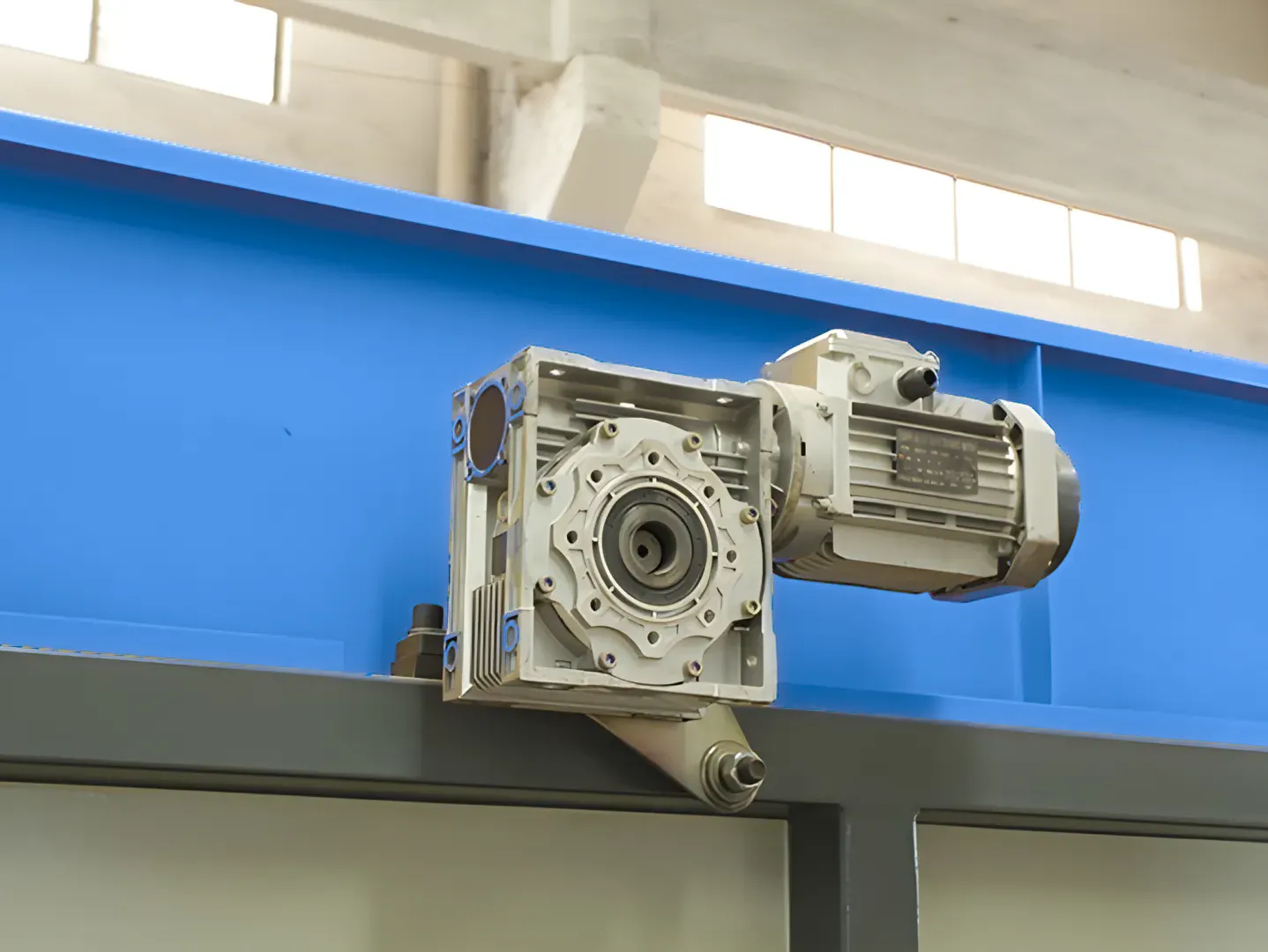

Equipped with rotating drums and screw conveyors to automatically separate, collect, and transport materials, minimizing manual labor and maximizing throughput.

Durable & Reliable Construction

Built with a Type 304 Stainless Steel interior and a robust carbon steel frame for exceptional longevity and resistance to corrosion in demanding, wet environments.

How Density Separation Works

Material Infeed

A mixed stream of crushed plastic flakes (PET, PP, PE) is fed into the water-filled tank.

Density Separation

Heavier PET flakes sink, while lighter PP/PE contaminants (caps, labels) float to the surface.

Automated Discharge

Rotating drums skim off floating materials, while a screw conveyor at the bottom collects and removes the pure, sunken PET flakes.

Technical Specifications

| Interior Width | 1500 mm – 2000 mm |

|---|---|

| Total Length | 4 meters – 6 meters (Customizable) |

| Interior Material | Type 304 Stainless Steel |

| Exterior Frame | Heavy-Duty Carbon Steel |

| Screw Conveyor Motors | 5.5 kW + 3.7 kW |

| Rotating Drum Motors | 2.2 kW + 0.37 kW |

| Control System | Independent control panel or PLC integration |

| Warranty | 1-Year Limited Warranty |

Frequently Asked Questions

What is the main advantage of this sink-float tank?

The primary advantage is achieving extremely high purity PET flakes. By perfectly separating materials based on density, you produce a higher-value final product that is free from common contaminants like PP and PE, which is critical for food-grade recycling applications.

What materials can this tank effectively separate?

It is specifically designed for PET bottle recycling. It excels at separating PET flakes from lighter plastics like Polypropylene (PP) and Polyethylene (PE), which are commonly used for bottle caps and labels. It can also separate other mixed rigid plastics with different densities.

What processing capacities do you offer?

We offer standard models in 4-meter and 6-meter lengths to suit various throughput requirements. However, as manufacturers, we can provide custom-sized solutions tailored to your facility's specific capacity goals and layout.

Enhance Your PET Recycling Process Today

Ready to boost your recycling efficiency and the purity of your final product? Contact us for the latest pricing, lead times, and customization options for our sink-float separation tanks.

Comments are closed.