The global push for a circular economy has turned the spotlight on one of the most challenging yet lucrative forms of plastic waste: discarded fishing gear. Often referred to as “ghost gear,” these end-of-life nets are primarily composed of high-quality materials such as Polyamide (PA6/Nylon), Polypropylene (PP), and Polyethylene (PE). However, the very properties that make fishing nets effective—immense tensile strength, elasticity, and resistance to degradation—make them notoriously difficult to recycle using standard equipment.

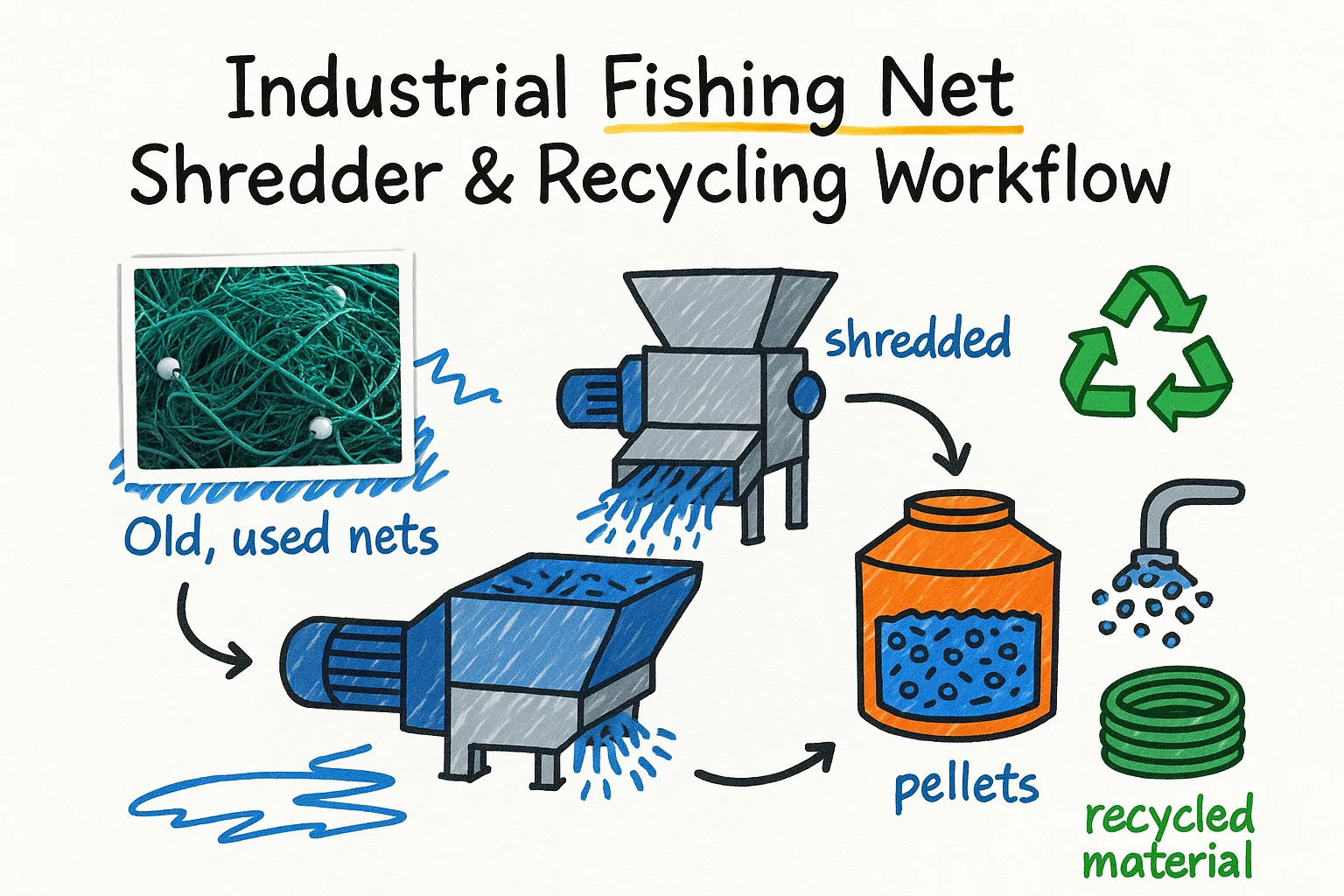

For recycling facility operators and industrial investors, the key to unlocking the value in this waste stream lies in selecting the right machinery. A standard plastic crusher will often fail when facing the durability of marine ropes and trawling nets. This article outlines the technical workflow required to process fishing nets efficiently, centering on the critical role of a robust fishing net shredder and a comprehensive washing-extrusion system.

The Challenge: Why Standard Shredders Fail

Before diving into the workflow, it is essential to understand why fishing nets cause bottlenecks in generic recycling lines.

- Entanglement: Fishing nets are designed to trap. In a recycling context, loose nets tend to wrap around the rotor of a standard shredder, causing motor burnout, bearing damage, and significant downtime.

- Abrasive Contaminants: Recovered nets are often filled with sand, shells, salt, and heavy metals (like lead weights). This creates high wear on blades and screens.

- High Tensile Strength: Cutting through thick marine-grade nylon ropes requires high torque and specific blade geometries that many general-purpose machines lack.

At Energycle, we engineer our solutions specifically to handle these extreme conditions, ensuring high throughput and minimal maintenance intervention.

Step 1: Sorting and Pre-treatment

The first stage of the process determines the quality of the final pellet. Fishing nets rarely arrive as a mono-material stream. They are often bundles of mixed plastics, ropes, buoys, and lead weights used to sink the nets.

Manual and Mechanical Sorting

Before the material enters the shredder, large contaminants must be removed.

- De-baling: Hydraulic guillotines may be used to shear large, compacted bales of nets into manageable sizes.

- Metal Detection: Removing lead weights and steel hooks is critical to protecting the downstream shredder blades.

- Material Segregation: Separating PA6 (Nylon) nets from PE/PP nets is vital, as these polymers have different melting points and cannot be extruded together.

Step 2: The Core Process – Heavy-Duty Shredding

This is the heart of the operation. To reduce bulky, tangled nets into uniform shreds, you need a machine that balances high torque with smart cutting technology.

The Energycle Fishing Net Shredder Advantage

Our plastic shredders are engineered with an “anti-winding” shaft design specifically for fiber and net applications. Unlike standard crushers that rely on high speed, a fishing net shredder must utilize lower speeds with significantly higher torque to shear through the fibers without allowing them to wrap around the axis.

Key Technical Features:

- Rotor Configuration: We utilize a specialized V-cut or chevron rotor design. This guides the material toward the center of the cutting chamber, preventing side-wall buildup and ensuring a continuous cutting action.

- Blade Material: Given the potential for sand and shell abrasion, our blades are crafted from high-alloy tool steels (such as D2 or SKD11) and heat-treated for maximum wear resistance.

- Screen Sizing: The shredder reduces the nets into strips usually between 40mm and 100mm. This size is optimal for the subsequent washing phase, preventing clogs in the friction washers.

By utilizing a dedicated single-shaft shredder with a hydraulic ram pusher, Energycle ensures that even the most stubborn bales of trawling nets are fed consistently into the rotor, maximizing hourly throughput.

Step 3: Washing and Density Separation

Once the nets are shredded, the material is dirty, salty, and likely mixed with organic marine debris. The value of the final recycled pellet is directly proportional to its purity.

High-Speed Friction Washing

The shredded material enters a high-speed friction washer. Here, a fast-spinning rotor strikes the plastic shreds, using centrifugal force and water to scrub off sand, algae, and salt. The dirty water is ejected through a mesh screen, leaving the plastic significantly cleaner.

Sink-Float Separation Tanks

This stage utilizes the specific gravity of different plastics to separate materials.

- Polyolefins (PP/PE): These float in water (density < 1.0 g/cm³).

- Polyamides (Nylon) & PET: These sink in water (density > 1.0 g/cm³).

For a dedicated Nylon recycling line, the sink-float tank serves a dual purpose: it washes the material further while skimming off any floating contamination (like pieces of PP rope accidentally mixed in). This ensures the final PA6 flakes are chemically pure.

Step 4: Drying and Moisture Control

Moisture is the enemy of extrusion. Nylon, in particular, is hygroscopic, meaning it absorbs water. If wet flakes enter the extruder, the moisture turns to steam, causing bubbles and structural weakness in the final pellets.

Centrifugal and Thermal Drying

The washing line concludes with a two-step drying process:

- Centrifugal Dryer: Uses high-speed spinning to mechanically eject surface water, reducing moisture content to roughly 2-3%.

- Thermal Drying System: For materials like Nylon, hot air pipe drying is often necessary to reduce moisture levels further, preparing the flakes for the extruder.

Step 5: Extrusion and Pelletizing

The final transformation occurs in the extrusion line, converting clean, dry flakes into uniform granules (pellets) ready for manufacturing new products.

Compacting and Degassing

Energycle extruders are equipped with advanced filtration and degassing systems. Because fishing nets may still contain microscopic residues, our screen changers ensure that any remaining impurities are filtered out of the melt. Furthermore, vacuum degassing zones remove any volatile gases or residual moisture, ensuring the pellets are solid and void-free.

Pelletizing Options

Depending on the material type (Rigid vs. Flex) and the desired output, we offer:

- Strand Pelletizing: Ideal for high-viscosity materials like Nylon.

- Water-Ring Pelletizing: Efficient for PE/PP films and nets.

The result is a recycled resin that retains near-virgin physical properties, suitable for injection molding or fiber spinning applications.

Technical Insights: Why Equipment Durability Matters

In the recycling industry, downtime dictates profitability. Processing fishing nets is classified as “heavy-duty” recycling. Opting for budget, light-duty machinery often results in:

- Shaft Fractures: Caused by the shock load of shredding thick ropes.

- Rapid Blade Dullness: Requiring frequent stops for sharpening.

- Bearing Failures: Due to water and grit ingress.

Energycle machinery is built with oversized gearboxes, external bearing houses to prevent contamination, and PLC-controlled overload protection. Our systems automatically reverse the shredder rotor if a jam is detected, protecting the machine and the operator.

The Economic & Environmental Impact

Investing in a specialized fishing net recycling plant is not just an environmental service; it is a sound business decision. Recycled Nylon 6 (rPA6) commands a high market price due to its application in automotive parts, textiles, and industrial components. By closing the loop on marine plastics, recyclers can tap into the “Blue Economy,” accessing government grants and serving a growing market of eco-conscious manufacturers.

Conclusion: Partner with Energycle for Reliable Solutions

Recycling fishing nets requires more than just a machine; it requires a thoroughly engineered process. From the initial bite of the fishing net shredder to the final cut of the pelletizer, every step must be synchronized to handle the toughness of marine plastics.

Energycle provides turnkey solutions tailored to your specific input materials and capacity requirements. We don’t just sell equipment; we help you optimize your workflow for longevity and ROI.

Ready to launch or upgrade your recycling line?

Stop letting tough materials damage your profits. Contact Energycle today for a consultation on our heavy-duty shredding and washing systems. Let’s build a cleaner ocean and a stronger business together.