In today’s fast-paced industrial landscape, where sustainability is no longer optional but essential, efficient recycling solutions are critical for manufacturers and industry professionals. At Energycle Machine, we specialize in advanced recycling equipment designed to meet the demands of modern operations across the USA and Europe. One such innovation that’s gaining traction is the plastic film densifier—a powerful tool that transforms lightweight, bulky plastic waste into manageable, high-value resources. This article delves into what a plastic film densifier is, how it operates, its benefits, applications, and more, providing you with the insights needed to enhance your recycling processes.

Whether you’re a manufacturer dealing with post-production waste or a buyer of industrial recycling equipment, understanding plastic film densifiers can help optimize your operations, reduce costs, and contribute to environmental goals. Let’s explore this technology in detail.

What Is a Plastic Film Densifier?

A plastic film densifier, also known as an agglomerator or compactor in some contexts, is specialized machinery engineered to process thin, flexible plastic films into denser forms. These films, typically made from polyethylene (PE) or polypropylene (PP), are common in packaging, agriculture, and manufacturing but pose challenges due to their low density and high volume.

At its core, the plastic film densifier compresses and heats these materials to create compact granules or blocks, making them easier to handle, store, and transport. Unlike simple balers that merely bundle waste, densifiers actively alter the material’s structure through friction and thermal processes, resulting in a product ready for further recycling stages like extrusion or pelletizing.

Energycle Machine has been at the forefront of developing reliable densifiers tailored for industrial use. Our systems are built with durability in mind, ensuring they withstand the rigors of high-volume operations while maintaining energy efficiency. This technology is particularly vital in regions like the USA and Europe, where stringent regulations on plastic waste management drive the need for innovative solutions.

How Does a Plastic Film Densifier Work?

The operation of a plastic film densifier is a blend of mechanical ingenuity and thermal science, designed to handle wet or dry plastic films efficiently. Here’s a step-by-step breakdown of the typical workflow, which can be visualized as a streamlined process to maximize throughput and minimize waste.

Step-by-Step Equipment Workflow

- Material Feeding: Waste plastic films—such as LDPE, HDPE, PP, or even BOPP from packaging—are fed into the densifier’s hopper. This can include scraps from manufacturing, agricultural films, or post-consumer waste. The input material often has a thickness of less than 2mm and may contain moisture from washing processes.

- Shredding and Friction Generation: Inside the machine, high-speed rotating blades or screws (often powered by motors ranging from 55-75 kW) shred the films. The rapid motion creates friction, generating heat (typically up to 200°C) that softens the plastic without fully melting it. This semi-molten state allows for effective compaction.

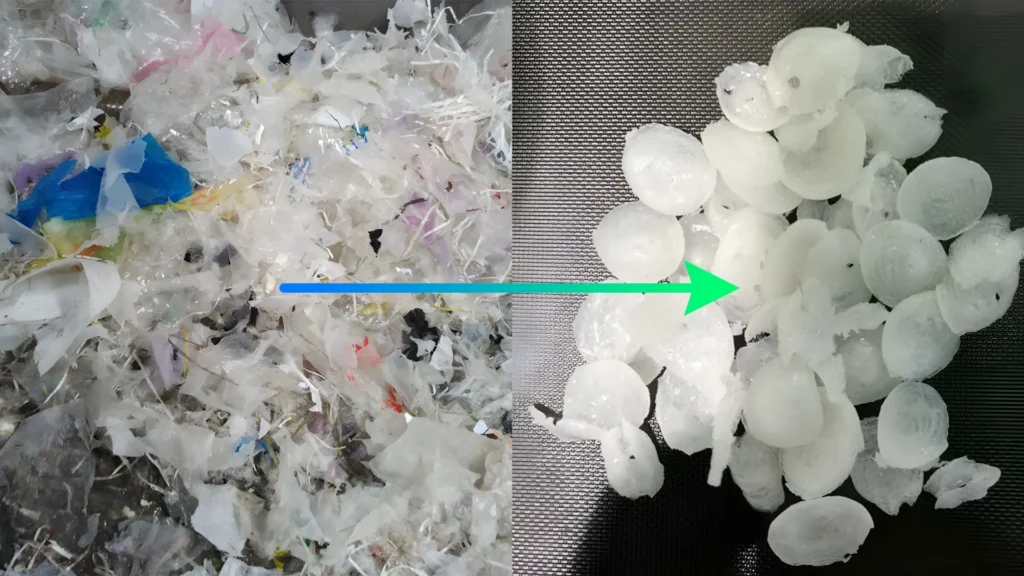

- Compression and Densification: The softened material is then squeezed through a screw-press or compaction chamber. In screw-press models, like those offered by Energycle Machine, the material is dewatered (reducing moisture from 30% to under 3%) and densified into a compact form. Air and water are expelled, increasing the bulk density significantly—often from a fluffy 50 kg/m³ to a solid 300-500 kg/m³.

- Cooling and Output: The densified material exits as granules, logs, or pellets, cooled via water or air systems to prevent sticking. These outputs are ready for granulation, extrusion, or direct sale to recyclers.

To illustrate this workflow clearly, imagine a linear process flow:

- Input: Bulky, wet films → Hopper

- Processing: Shredding → Friction Heating → Compression

- Output: Dense granules → Collection bin

This workflow not only reduces volume by up to 90% but also prepares the material for seamless integration into downstream recycling lines. At Energycle Machine, our densifiers incorporate automated controls for temperature and speed, ensuring consistent results and minimal operator intervention.

Key Benefits of Using a Plastic Film Densifier

Incorporating a plastic film densifier into your recycling setup offers multifaceted advantages, particularly for manufacturers and buyers focused on efficiency and sustainability.

- Volume Reduction and Cost Savings: By compacting films, densifiers drastically cut storage and transportation costs. For instance, what once filled a truck can now fit into a fraction of the space, lowering logistics expenses by 50-70%.

- Moisture Removal and Material Quality Improvement: Traditional methods often leave residual water, leading to degradation. Densifiers achieve moisture levels below 3%, enhancing the quality of recycled material and making it suitable for high-end applications.

- Energy Efficiency: Compared to full melting processes in extruders, densifiers use less energy since they operate at lower temperatures. This aligns with energy conservation goals in the USA and Europe, where regulations like the EU’s Circular Economy Package emphasize reduced carbon footprints.

- Environmental Impact: Densifying promotes mechanical recycling over landfilling or incineration, reducing greenhouse gas emissions by 8-23% per ton of plastic processed. It’s a step toward zero-waste operations, appealing to eco-conscious professionals.

Energycle Machine’s densifiers are engineered with these benefits in mind, featuring robust components that ensure long-term reliability and low maintenance costs.

Applications in Industry: Where Plastic Film Densifiers Shine

Plastic film densifiers find widespread use across sectors where plastic waste is abundant, helping industries turn liabilities into assets.

- Plastic Recycling Facilities: As a pre-treatment step, densifiers prepare films for granulation, enabling the production of recycled pellets for new products like bags or pipes.

- Packaging Waste Management: In the packaging industry, densifiers handle films from shrink wraps, bubble wraps, and grocery bags, facilitating closed-loop recycling.

- Agricultural Sector: Farmers and agribusinesses use them for processing mulch films and greenhouse covers, reducing on-site waste and supporting sustainable farming practices.

- Manufacturing and Industrial Waste: Factories producing textiles, electronics, or food packaging benefit from densifying scraps, integrating seamlessly into supply chains.

In the USA, where plastic film recycling rates are climbing toward 20%, and in Europe with its ambitious 55% recycling target by 2030, Energycle Machine’s solutions help meet these benchmarks. Our equipment is versatile, handling materials like PET fibers, nylon, and PVC alongside standard PE/PP films.

Comparing Plastic Film Densifiers to Other Recycling Methods

To highlight the value of densifiers, let’s compare them to alternative approaches using key performance metrics. This table provides a clear overview for technical readers evaluating options.

| Method | Volume Reduction | Moisture Removal | Energy Consumption | Cost Efficiency | Environmental Impact |

|---|---|---|---|---|---|

| Plastic Film Densifier | High (up to 90%) | Excellent (<3%) | Low to Medium | High (reduces transport costs) | Low emissions; promotes mechanical recycling |

| Baling | Medium (50-70%) | Poor (no removal) | Low | Medium (still bulky) | Moderate; risk of contamination |

| Chemical Recycling | Variable | Good | High (solvents/heat) | Low (complex process) | Medium; handles mixed plastics but higher CO2 |

| Extrusion/Pelletizing Direct | High | Medium | High (full melt) | Medium | Low if efficient; but energy-intensive |

| Landfilling/Incineration | None | N/A | N/A | Low initial, high long-term | High emissions; resource waste |

As shown, densifiers excel in balancing efficiency and sustainability, especially for film-specific waste. They outperform baling in quality preparation and are more energy-efficient than chemical methods for clean streams. Energycle Machine recommends densifiers for operations prioritizing mechanical recycling, as they integrate well with existing lines without requiring extensive overhauls.

Technical Insights: Specifications and Considerations

For industry professionals, understanding technical specs is crucial. While exact figures vary by model, typical plastic film densifiers feature:

- Capacity: 100-1000 kg/h, scalable for small manufacturers to large facilities.

- Motor Power: 55-200 kW, with variable speed controls for optimal friction.

- Dimensions: Compact designs (e.g., 2-3m length) fitting into standard industrial spaces.

- Material Handling: Suitable for films <2mm thick; options for wet/dry input.

- Safety Features: Enclosed chambers, automatic shutdowns, and noise reduction (<85 dB).

Energycle Machine’s systems, such as our Plastic Film Squeezer Densifier System, incorporate advanced hydraulics and double-bearing shafts for durability. When selecting a densifier, consider your throughput needs, material types, and integration with granulators—factors we address in custom consultations.

Frequently Asked Questions (FAQ)

Here are answers to some common queries about plastic film densifiers, based on insights from industry experts.

- What types of plastic films can a densifier process?

Densifiers handle a wide range, including PE (LDPE/HDPE), PP, BOPP, PVC, and PET fibers, as long as the thickness is under 2mm. They’re ideal for both clean and washed films. - How does a densifier improve recycling efficiency?

By reducing volume and moisture, it lowers costs and prepares material for pelletizing, increasing the value of recycled plastics and supporting circular economies. - What maintenance is required for a plastic film densifier?

Regular blade sharpening, lubrication, and cleaning of the chamber are key. Energycle Machine’s models feature easy-access designs, minimizing downtime to just a few hours per month. - Is a densifier cost-effective for small operations?

Yes, entry-level models start at capacities of 100 kg/h and offer quick ROI through reduced waste disposal fees and material sales.

Conclusion: Embrace Innovation with the Energycle Machine

Plastic film densifiers represent a cornerstone of modern recycling, offering manufacturers and professionals a pathway to efficiency, sustainability, and profitability. At Energycle Machine, we’re committed to advancing this technology, drawing on our expertise to deliver solutions that reflect credibility and innovation in the recycling machinery industry.

Ready to transform your plastic waste management? Contact Energycle Machine today to learn more about our Plastic Film Squeezer Densifier System or request a personalized quote. Let’s build a greener future together—reach out via our website or call our team for expert guidance.