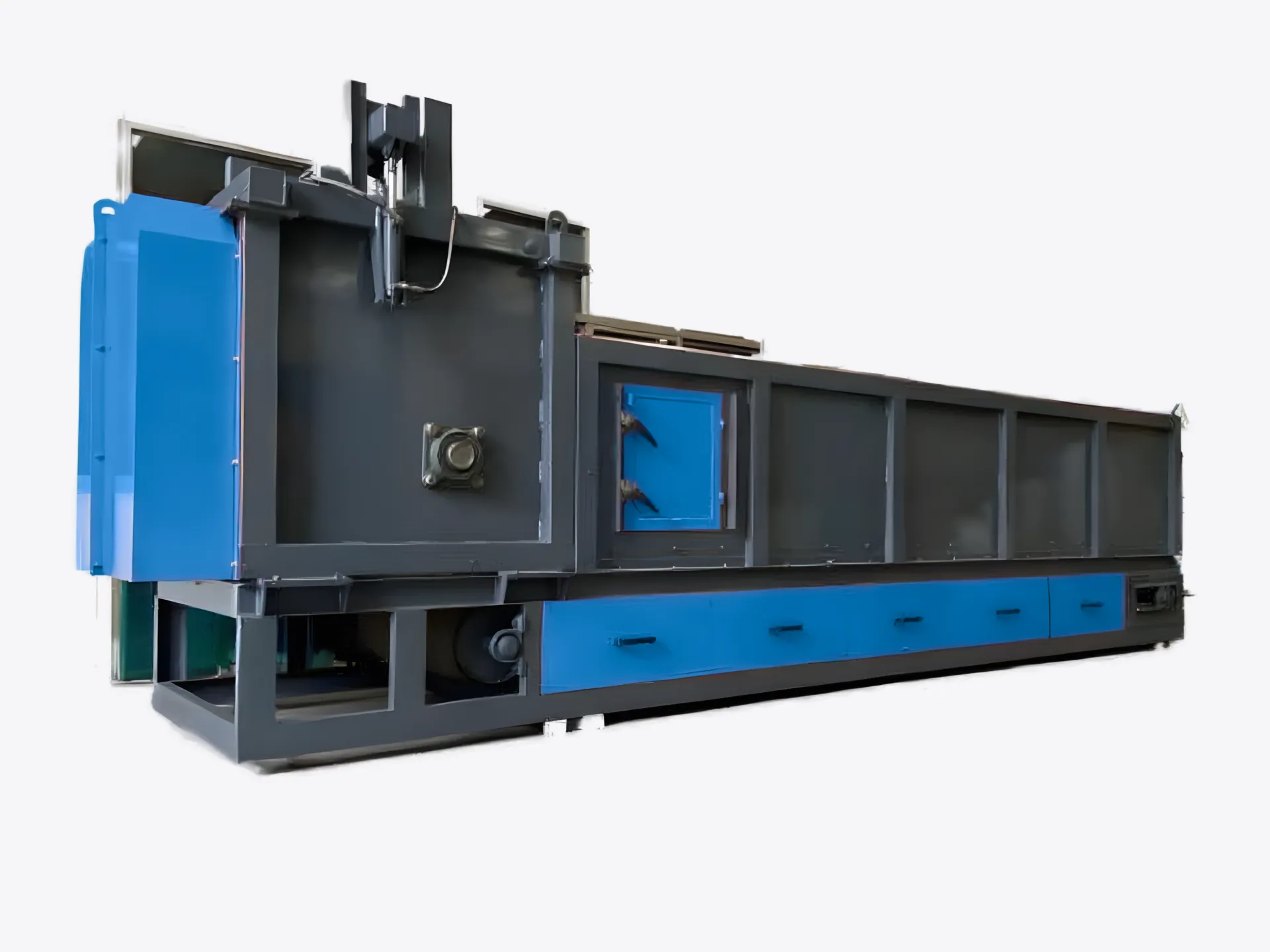

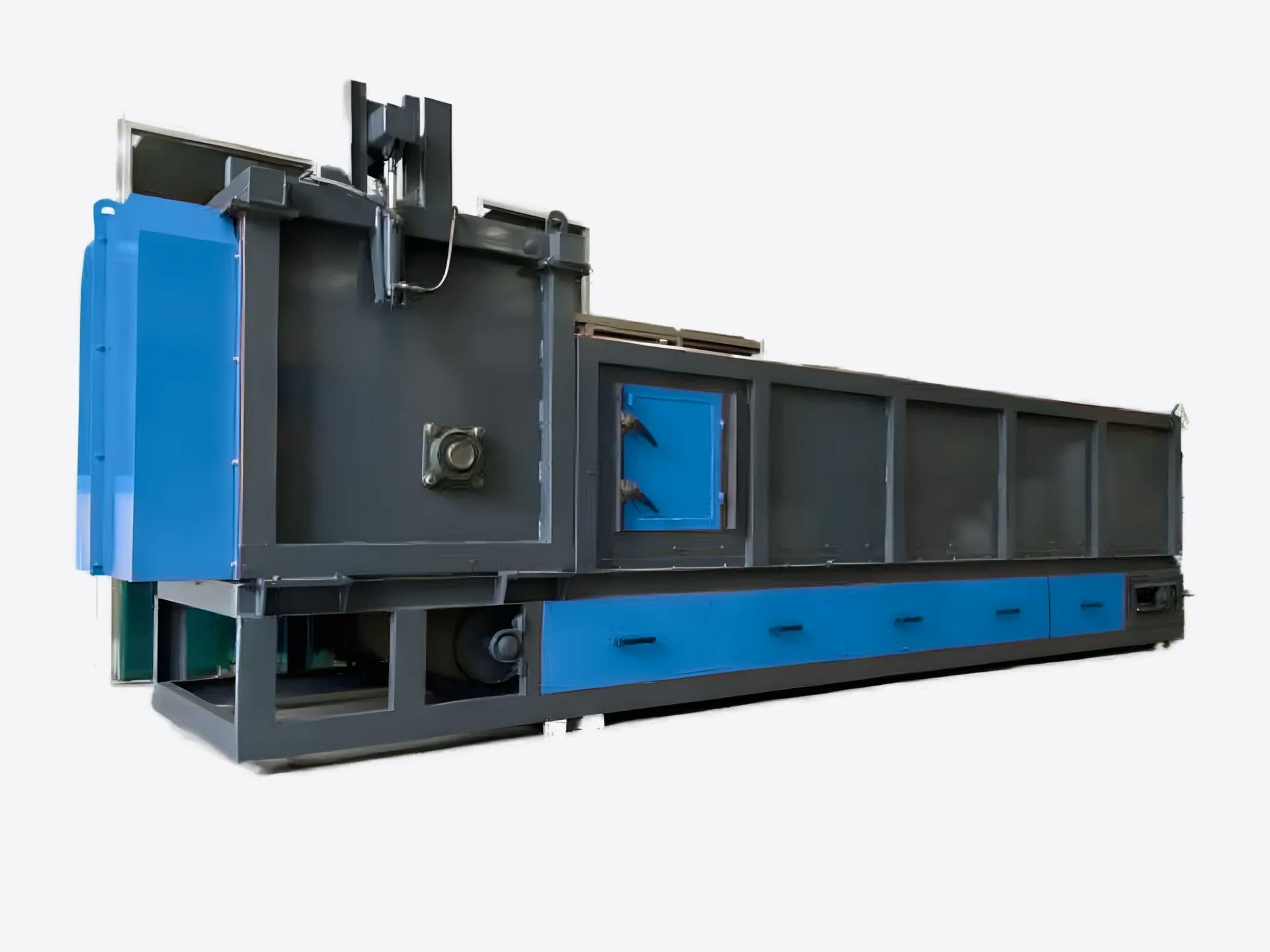

Intelligenter Sackaufreißer und Ballenöffner

Die robuste, hocheffiziente Front-End-Lösung für große MSW-Sortier- und PET-Recyclinglinien.

Fordern Sie eine individuelle Lösung und ein Angebot anKernkompetenzen

Entwickelt für anspruchsvolle Umgebungen, um Ihre Betriebseffizienz und Automatisierung deutlich zu steigern.

Leistungsstarke Vielseitigkeit

Verarbeitet effizient sowohl in Säcken verpackten Hausmüll als auch hochverdichtete Ballen aus PET-Flaschen oder Kunststofffolien.

Außergewöhnliche Befreiung

Erreicht eine Sacköffnungsrate von über 98% und entdichtet Ballen effektiv, ohne das Kernmaterial zu beschädigen.

Robust und langlebig

Hergestellt aus hochfesten, verschleißfesten Materialien und einem Hochleistungsantriebsstrang für langfristige Zuverlässigkeit unter hoher Belastung.

Wie es funktioniert

Ein optimierter Prozess zur Freigabe zweier unterschiedlicher Materialtypen.

In Säcke verpackter Siedlungsabfall (MSW)

Verdichtete PET-Ballen

Freier und gleichmäßiger Materialfluss

Bereit für die nachgelagerte Sortierung

Technische Eigenschaften

Jedes Detail ist sorgfältig konstruiert, um eine überragende Leistung und geringere Betriebskosten zu erzielen.

Modulare verschleißfeste Messer

Speziell wärmebehandelte Messer aus legiertem Stahl können einzeln ausgetauscht werden, wodurch Ausfallzeiten und Wartungskosten minimiert werden.

Intelligentes Steuerungssystem

Verfügt über eine SPS-Steuerung mit lastadaptiver Regelung, eine automatische Rückwärtsfunktion zur Vermeidung von Staus und Fernüberwachungsfunktionen.

Erweiterter Antriebsstrangschutz

Ausgestattet mit mechanischem und elektrischem Überlastschutz sowie Labyrinthdichtungen, um eine Staubkontamination der Lager zu verhindern.

Optimierter Anti-Verwicklungsschaft

Eine speziell strukturierte Hauptwelle verhindert das Aufwickeln von Folien, Textilien und anderen flexiblen Materialien und gewährleistet so einen kontinuierlichen Betrieb.

Technische Spezifikationen

| Parameter | Modell BO-30 | Modell BO-50 | Modell BO-80 |

|---|---|---|---|

| Verarbeitungskapazität (t/h) | 5-10 | 10-20 | 20-30 | Anwendbare Materialien | Abgepackter Hausmüll, PET/HDPE-Flaschenballen, Folienballen, andere verdichtete Kunststoffe |

Anwendungen & Galerie

Von städtischen Abfallentsorgungsanlagen bis hin zu großen Kunststoffrecyclinganlagen – unsere Ausrüstung hat sich in der Praxis bewährt.

Starten Sie Ihr nächstes Kapitel im effizienten Recycling

Kontaktieren Sie uns noch heute für eine individuelle Lösung und ein detailliertes Angebot, das auf Ihren spezifischen Materialstrom zugeschnitten ist.

Häufig gestellte Fragen

Werden die Flaschen bei der Verarbeitung von PET-Ballen beschädigt?

Nein, das tut sie nicht. Unsere Maschine arbeitet nach dem Prinzip der „Befreiung“, nicht des „Zerkleinerns“. Die langsam laufenden Messer mit hohem Drehmoment sind so konzipiert, dass sie die Ballenbänder zerreißen und die komprimierten Flaschen schonend trennen. Jeder Kontakt mit den Flaschen verursacht lediglich leichte Kratzer, die die nachfolgenden optischen Sortier- oder Waschprozesse nicht beeinträchtigen.

Wie hoch ist die Lebensdauer der Messer und wie hoch sind ihre Ersatzkosten?

Die Messer bestehen aus hochverschleißfestem legiertem Stahl und haben eine typische Lebensdauer von 1500–2000 Betriebsstunden. Ihr modularer Aufbau ermöglicht den einfachen, individuellen Austausch nur der verschlissenen Abschnitte. Wir bieten wettbewerbsfähige Preise für Ersatzteile, um Ihre Betriebskosten langfristig niedrig zu halten.

Kann diese Maschine in meine bestehende Produktionslinie integriert werden?

Absolut. Wir bieten standardisierte Ein- und Ausgabeschnittstellen für die nahtlose Anbindung verschiedener Förderer (Platten, Bänder) und nachgelagerter Anlagen wie Trommelsiebe. Unsere Ingenieure unterstützen Sie auch bei der Linienplanung, um eine perfekte Integration zu gewährleisten.