PP Woven Bags & Raffia Recycling Line

Engineered for post-consumer PP woven sacks, raffia tape/yarn, and FIBC scrap with dust, sand, ink, and residual organics. The line integrates controlled feeding, low-speed shredding, wet granulation, intensive washing, and staged drying to deliver PP flakes sized and conditioned for extrusion—plus optional pelletizing.

- Feedstock: PP woven sacks, raffia (tape/yarn), and FIBC scrap

- Cleaning stages: friction washing + rinsing/separation (hot wash optional)

- Residual moisture: typically < 3% with thermal drying (feedstock dependent)

- Typical throughput: 300–1500 kg/h (configuration dependent)

Decision Drivers

Primary selection factors that drive module choice, utilities sizing, and output consistency.

Contamination Tolerance

Configured for sand/grit, paper fibers, ink, light oils, and residual organics typical in post-consumer sacks and raffia.

Flake Size Control

Primary shredding + wet granulation set a stable flake size window for washing efficiency and downstream extrusion feeding.

Moisture Targets

Dewatering and thermal drying are selected to hit a defined residual moisture target for extrusion stability and optional pelletizing.

Wear and Service Access

Rotor/knife design, screen strategy, and bearing protection are selected for abrasive contamination and predictable maintenance intervals.

Water Loop and Energy Load

Washing loop and heating (if used) are sized to the contamination profile, balancing cleaning performance with utilities demand.

Automation and Safety Interlocks

Line-level control logic supports steady throughput with overload protection, interlocks, and module-by-module permissives.

Supported Feedstock Forms

Typical incoming materials for this line (share photos/samples and contamination details for configuration selection).

PP Woven Bags

Cement bags, fertilizer sacks, rice bags, and other printed woven sacks.

PP Non-Woven

Non-woven fabric scraps and bags (PP), with optional deeper washing.

PP Raffia (Tape/Yarn)

Raffia strips, tapes, and yarn waste from weaving and packaging operations.

BOPP-Laminated Woven Bags

Laminated woven bags and printed layers (configured based on contamination).

.webp?fit=crop&auto=format,compress&fm=webp)

Jumbo Bags (FIBC)

Bulk bags and big bags, including dusty or sand-contaminated material.

PP Woven Offcuts

Weaving trims and offcuts. Cleaning intensity and dewatering stages are selected based on dust, sand load, and ink/lamination.

Process Flow

Reference process sequence from size reduction through washing and staged drying. Final configuration depends on contamination profile, target flake size, and downstream extrusion requirements.

Feeding & Pre-Sorting

Metered feeding with optional metal detection or manual pre-sorting to reduce tramp contaminants.

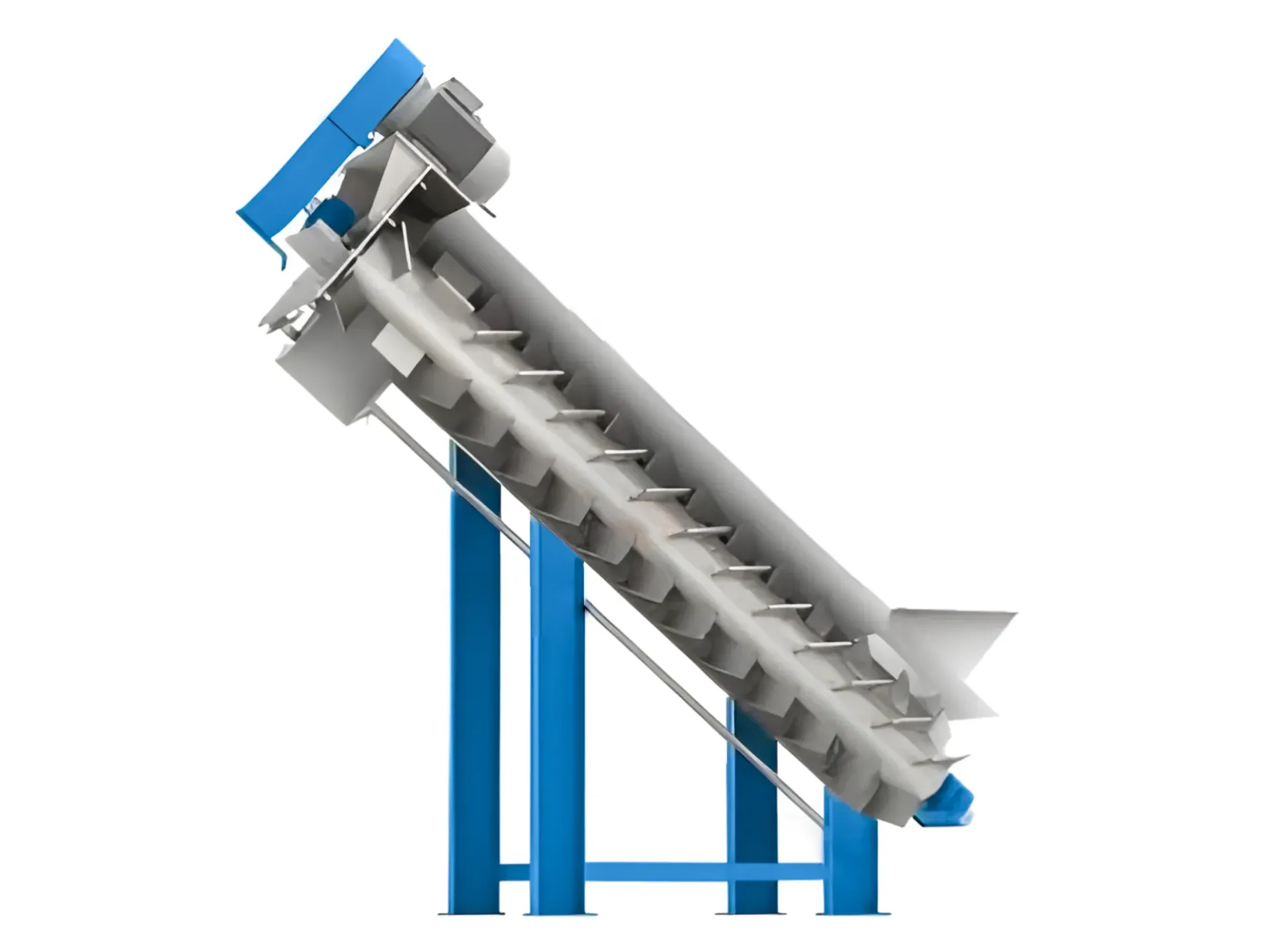

Shredding

Low-speed, high-torque size reduction to open woven structures and stabilize downstream cutting.

Wet Granulation

Water-assisted cutting to a defined flake size range for improved washing and rinsing efficiency.

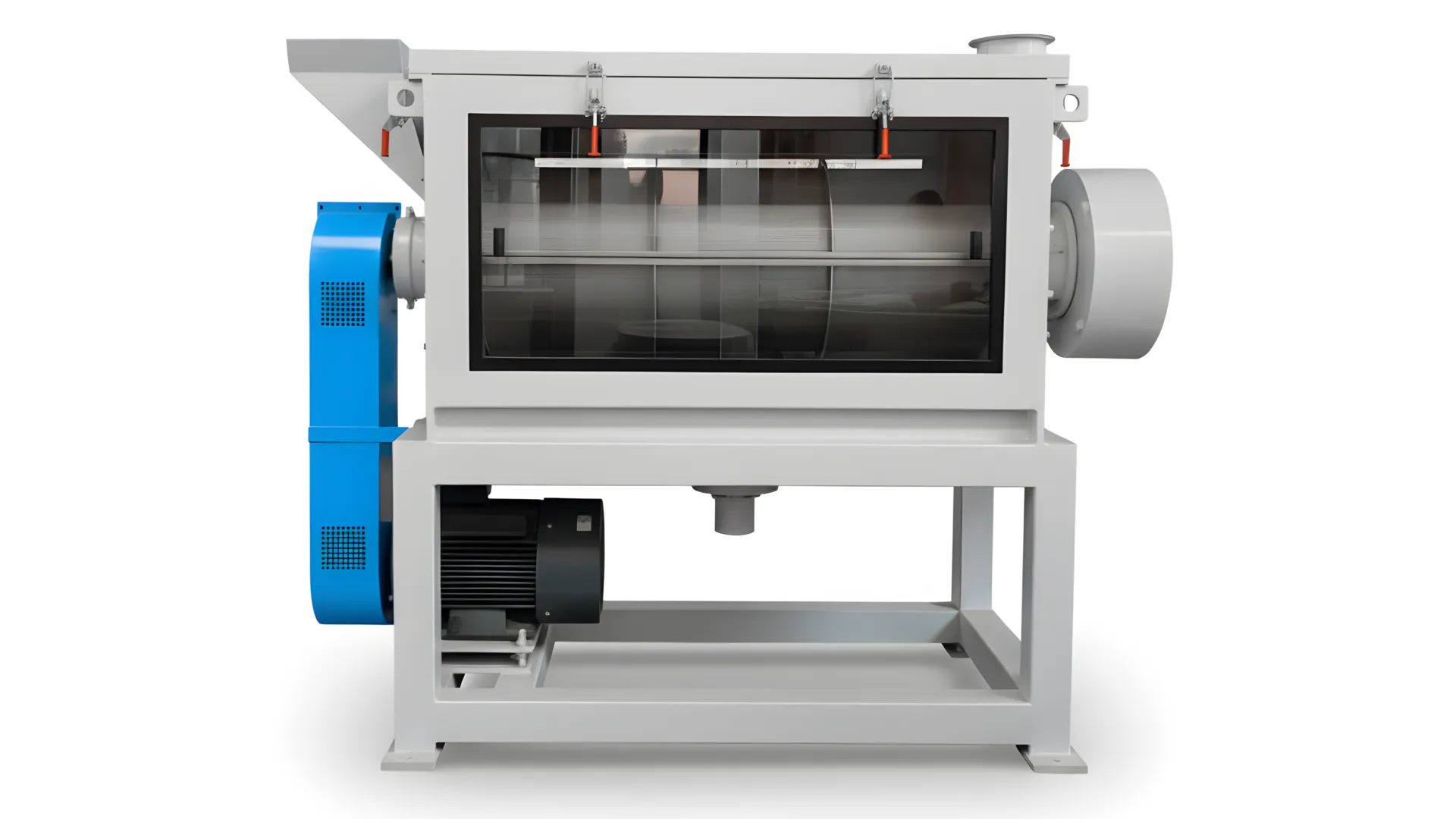

Friction Washing

High-shear scrubbing to remove sand/dust, loosened ink, and attached fibers from PP flakes.

Rinsing & Separation

Rinse and density-based separation to reduce heavy carryover and improve PP purity.

Dewatering & Drying

Mechanical dewatering followed by thermal drying (and optional squeezer) to meet a moisture target for extrusion.

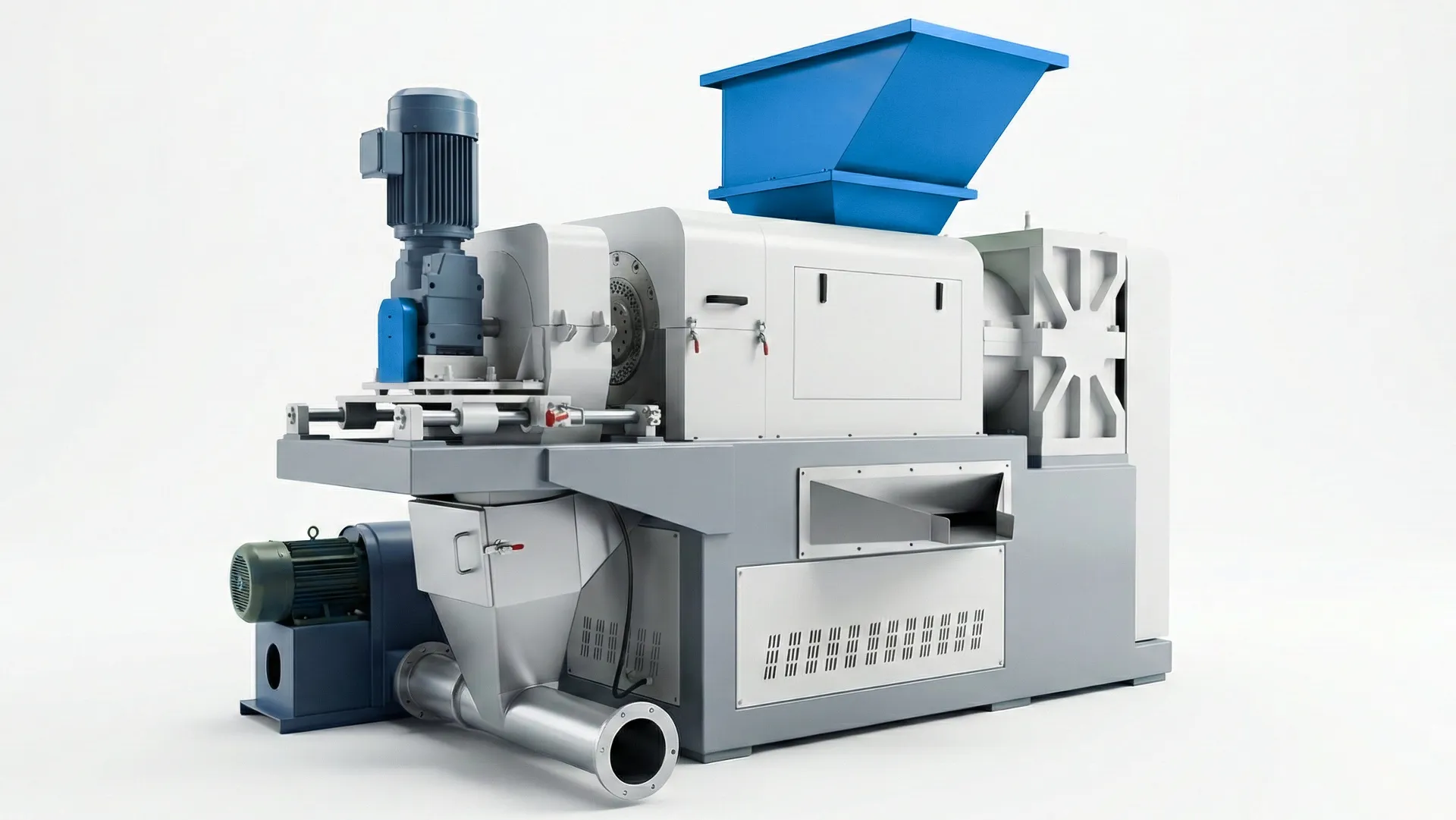

Pelletizing (Optional)

Optional conversion of conditioned flakes to pellets when storage, dosing, or downstream feeding requires it.

Utilities and Footprint

Reference utilities and layout envelope by capacity tier (final sizing depends on contamination level and selected modules).

| Capacity (kg/h) | Install Power (kW) | Typical Layout Area (m²) | Operators / Shift | Compressed Air (MPa) | Process Water (m³/h) |

|---|---|---|---|---|---|

| 300 | 150 | 350 | 4 | 0.6-0.8 | 3 |

| 500 | 230 | 460 | 6 | 0.6-0.8 | 4 |

| 1000 | 430 | 500 | 6 | 0.6-0.8 | 5 |

Note: Values are indicative. Final utilities depend on contamination profile, hot washing/heating selection, and drying configuration.

Utilities guidance: electrical supply is specified by voltage/Hz and start method; water demand depends on open vs closed loop design and hot washing/heating selection.

Key Modules

Belt Conveyor Specifications

- Frame: Carbon steel or SS304 (options)

- Belt Type: PVC/PU (application dependent)

- With belt tensioning device and receiving hopper

- Belt Width & Length: Sized to throughput and layout

- Transporting raw materials into the system.

Single-Shaft Shredder Specifications

- Rotor Speed: 60–100 RPM (typical)

- Knife Material: D2 or alloy tool steel (application dependent)

- Screen Size: 40–100 mm (set by downstream cutting and washing)

- Hydraulic Pusher: Yes (for stable feeding under load)

- Motor Power: Sized by capacity and feedstock (typ. 30–200 kW)

- Opens woven structures and reduces bulk volume.

- Stabilizes downstream cutting and washing consistency.

- Reduces bridging and improves feeding control.

Wet Plastic Granulator Specifications

- Rotor Speed: 400–600 RPM (typical)

- Blade Material: D2 tool steel (common)

- Knife Arrangement: V-cut or scissor-cut (by material behavior)

- Screen Filter Size: 20–60 mm (typical for PP woven/raffia lines)

- Produces flakes sized for washing and rinsing efficiency.

- Reduces dust carryover by wet cutting and immediate rinsing.

- Improves feeding stability for dewatering and drying stages.

Friction Washer Specifications

- Rotor Speed: 500-600 RPM

- Water System: Top inlet, bottom outlet

- Operation: Continuous

- Cleaning Method: High-speed friction

- Removes sand/dust and loosened ink/fiber contamination.

- Transfers material between stages with controlled residence time.

- Reduces abrasive carryover into dewatering and drying.

Floating Separation Tank Specifications

- Interior Width: 1000mm - 1800mm

- Total Length: 4 - 7 meters

- Interior Material: Type 304 Stainless Steel

- Exterior Frame: Carbon Steel

- Paddle Motors: 1.5KW × 2 (frequency control)

- Geometry configured for stable separation and rinsing.

- Sectioned design supports staged rinsing and contamination management.

- Water loop can be configured for open or closed operation.

Hot Washer Specifications

- Operation Mode: Continuous or batch (by contamination)

- Heating Options: Electric, steam, or boiler integration (site dependent)

- Washing Method: Heated wash with optional chemical dosing

- Use Case: Ink, oils, glue, and heavy organics (when required)

- Improves removal of oils, glue, and stubborn organics when specified.

- Heating and chemistry are configured by cleanliness target and utilities.

- Integrated into the wash loop with controlled temperature and residence time.

Centrifugal Dryer Specifications

- Rotation Speed: ~1,000 RPM (typical)

- Moisture Reduction: Often ~20–30% (feedstock dependent)

- Main Components: Rotor with paddles, mesh screen tunnel

- Configuration: Sized by throughput and inlet water load

- Reduces thermal drying load by removing free water mechanically.

- Continuous operation for stable line throughput.

- Configured with wear protection for abrasive fines.

Thermal Pipe Dryer Specifications

- Drying Method: Hot air conveying with cyclone separation

- Heat Input: Electric or thermal integration (site dependent)

- Pipe Material: SS304 (common) with abrasion options

- Configuration: Single or multi-stage (by capacity and target moisture)

- Controls: Temperature and airflow control for stable drying

- Continuous drying for stable extrusion preparation.

- Cyclone separation helps manage fines and lightweight contamination.

- Configured to meet a defined residual moisture target.

- Scalable with multiple stages for higher throughput.

Film Squeezer Specifications

- Moisture Reduction: Typically reduces moisture from ~10–35% down to ~1–8% (inlet dependent)

- Mechanism: Screw-type compression and heating/friction densifying

- Output Capacity: 300–1500 kg/h (matched to line throughput)

- Energy Consumption: Sized by capacity and densifying requirement

- Reduces moisture and increases bulk density for feeding stability.

- Improves dosing consistency to extrusion/pelletizing.

- Optional stage selected when thermal drying alone is not optimal.

Water Ring Pelletizing System (Optional)

- Pellet Type: Water-ring cut, uniform granules

- Typical Inputs: Clean PP flakes from woven bags, raffia, and FIBC scrap

- Customization: Die face, filtration, and automation options

- Pelletizes conditioned PP flakes with stable die-face cutting.

- Improves handling and dosing versus loose flakes.

- Filtration and automation options are selected by pellet quality target.

Field Performance Notes

Representative operating observations (anonymized). Results depend on feedstock and configuration.

Printed cement sacks with heavy sand load: hot wash enabled and higher friction-wash intensity reduced abrasive carryover into drying and improved flake cleanliness.

Raffia tape/yarn scrap with light organics: controlled granulation improved rinse efficiency and stabilized downstream feeding for extrusion preparation.

Mixed woven + FIBC scrap: moisture target was achieved by selecting dewatering + thermal drying stages appropriate to the inlet water load (squeezer optional).

Technical FAQs

Decision-oriented answers for selecting modules, utilities, and output targets.

What PP materials can this line process?

Designed for PP woven sacks, raffia (tape/yarn), FIBC scrap, and PP non-woven. BOPP-laminated woven bags are supported when washing intensity and hot washing (if required) are selected to match ink/adhesive contamination.

What output and moisture level can I expect?

Throughput is typically 300–1500 kg/h depending on module selection and contamination load. Residual moisture depends on dewatering and drying stages; thermal drying is commonly used to reach < 3% when required for stable extrusion (feedstock dependent).

Do I need hot washing for printed cement bags or oily contamination?

Specify hot washing when ink, oils, glue, or heavy organics must be reduced to meet an output cleanliness target. For light dust/sand loads, friction washing + rinsing may be sufficient. Heating method and chemistry depend on site utilities and the contamination profile.

Can this line produce PP pellets directly?

Yes—add extrusion/pelletizing. If the inlet water load is high or pelletizing stability is critical, a squeezer is often selected to reduce moisture and increase bulk density before extrusion. Filtration is specified by the pellet quality target.

Can you customize the layout and automation level?

Yes. Layout, module selection, and control logic are configured around capacity, contamination, available utilities, and footprint. Typical automation includes interlocks, overload protection, and module-by-module permissives; higher automation levels can be specified in the RFQ.

RFQ Requirements

Provide the minimum inputs below so we can size modules, utilities, and layout for your PP woven/raffia stream.

- Feedstock type(s): woven sacks, raffia (tape/yarn), FIBC, BOPP-laminated (yes/no)

- Contamination: sand/dust %, ink/adhesive, oils/organics, moisture at inlet

- Target throughput (kg/h) and operating hours per day

- Target output: flake size range and cleanliness/moisture requirement for extrusion

- Utilities available: voltage/Hz, heating source, water loop preference (open/closed)

- Space constraints: available length/width, elevation limits, material handling constraints

- Automation level and commissioning preference (remote/on-site)