Technischer Leitfaden · Auswahl des Klingenmaterials

SKD-11 vs D2 vs DC53 vs 55SiCr: Der beste Klingenstahl für Kunststoff-Aktenvernichter

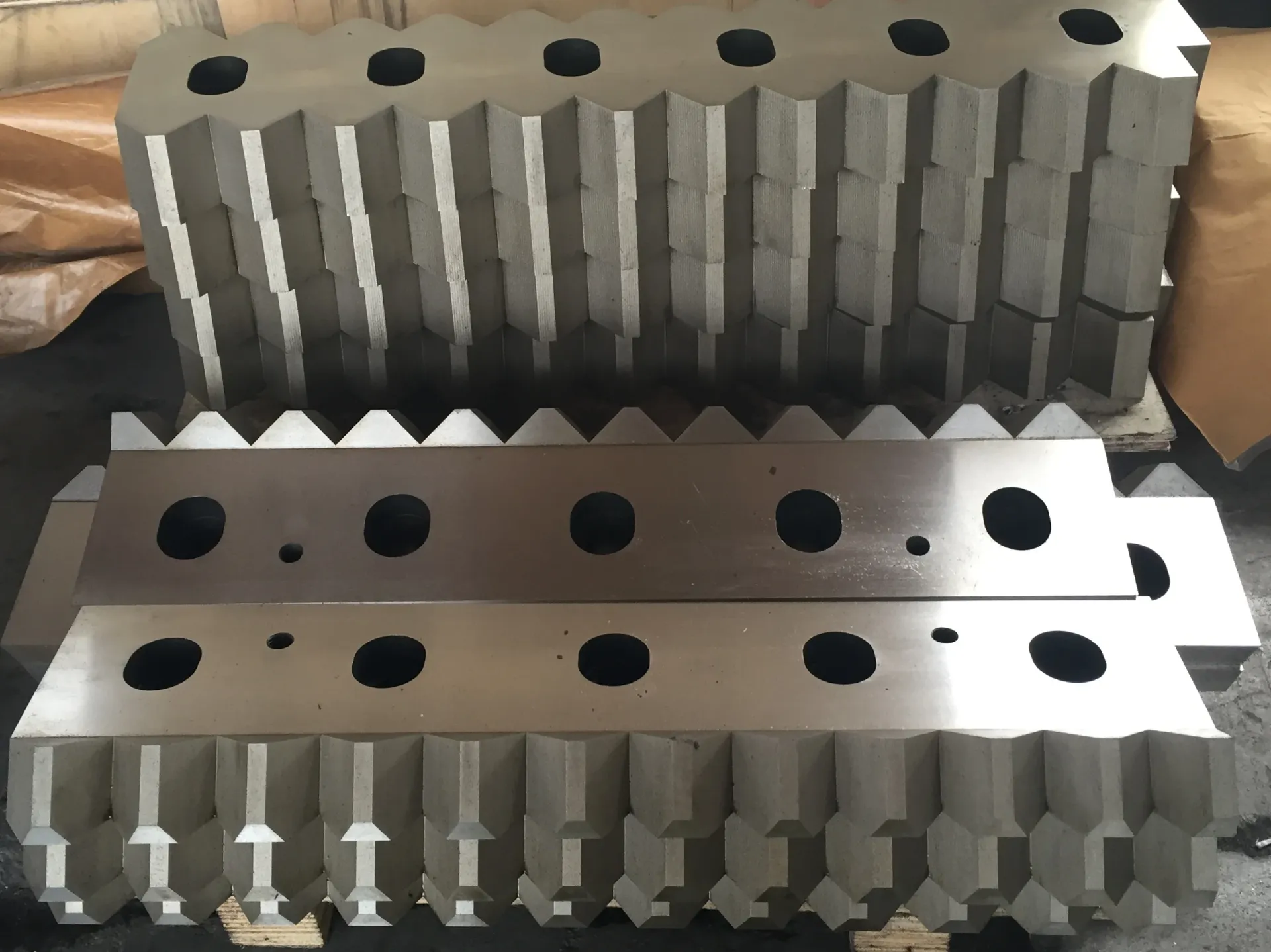

Die Wahl des Sägeblattmaterials hat direkten Einfluss auf Schneidleistung, Standzeit, Energieverbrauch und Ausfallzeiten beim Kunststoffrecycling. Dieser Leitfaden vergleicht vier weit verbreitete Sägeblattstähle – SKD-11 (entspricht D2), D2, DC53 und 55SiCr – damit Sie das passende Material für Ihre Kunststoffart, den Verschmutzungsgrad und die Betriebsbedingungen auswählen können.

Warum das Klingenmaterial wichtig ist

In Kunststoffzerkleinerern und -brechern sind die Messer ständigem Abrieb, Stoßbelastungen, Hitzeentwicklung und gelegentlicher Metallverunreinigung ausgesetzt. Die Wahl der falschen Stahlsorte führt typischerweise zu schnellem Schneidenverschleiß, Ausbrüchen, häufigem Nachschärfen, instabiler Partikelgröße und erhöhtem Energieverbrauch. Die Wahl der richtigen Stahlsorte verbessert die Maschinenverfügbarkeit und senkt die Gesamtkosten pro verarbeiteter Tonne.

Faustregel: Bei stark abriebbelasteten Kunststoffen ist Verschleißfestigkeit von Vorteil. Stoßbelastete oder verunreinigte Ströme erfordern eine höhere Zähigkeit.

Kurzempfehlungen

Am besten geeignet für abrasive Materialien

D2 / SKD-11 für lange Lebensdauer in starren Kunststoffen und abrasiven Medienströmen (z. B. gefüllte Kunststoffe, verschmutztes Mahlgut).

Optimale Balance (Verschleißfestigkeit + Zähigkeit)

DC53 wenn sowohl Verschleißfestigkeit als auch Schlagzähigkeit erforderlich sind (gemischte Kunststoffe, PVC, gummiartige/variable Zuführung).

Ideal für Stoß- und Schlagbelastungen

55SiCr für Bedingungen mit plötzlichen Stößen, Vibrationen oder häufigen harten Einschlüssen – oft dort eingesetzt, wo Zähigkeit Priorität hat.

Bester Ausgangspunkt

Wenn Sie sich unsicher sind, beginnen Sie mit DC53 Bei gemischten Materialströmen sollte die Optimierung nach Auswertung der Verschleißdaten und der Schärfintervalle erfolgen.

Die endgültige Leistung hängt auch von der Geometrie der Schneidmesser, der Wärmebehandlung, dem Schneidspalt, der Rotordrehzahl und davon ab, ob es sich um einen Schredder oder einen Brecher handelt. Selbst eine hohe Stahlsorte kann eine falsche Schneideinstellung nicht ausgleichen.

Materialvergleichstabelle

| Stahlgüte | Verschleißfestigkeit | Zähigkeit | Optimale Anwendungsfälle | Typische Kunststoffe |

|---|---|---|---|---|

| SKD-11 (D2-Familie) | Sehr hoch | Medium | Lange Laufzeit, stabile Schneide | ABS, PS, PA/Nylon, Hartmetallgranulat |

| T2 - Der zweite Tag | Sehr hoch | Medium | Schleifmittel/schmutzige Materialien, gefüllte Kunststoffe | GF-gefüllte Kunststoffe, gemischte, starre, zähe Mahlgut |

| DC53 | Hoch | Hoch | Optimale Balance für variable Rohstoffe | PVC, gemischte Kunststoffe, Gummi, uneinheitliche Ströme |

| 55SiCr | Medium | Sehr hoch | Stoßbelastungen | Weichere Kunststoffe, verschmutzte Bäche durch Umwelteinflüsse |

Notiz: “Am besten” hängt von Ihrem Abfallaufkommen ab. Eine Klinge, die bei sauberen, starren Kunststoffen am längsten hält, kann bei stark beanspruchten Mischabfällen abplatzen.

Materialprofile

SKD-11 (oft verglichen mit D2)

- Stärke: ausgezeichnete Verschleißfestigkeit und stabile Schnitthaltigkeit.

- Am besten geeignet für: Langzeitkampagnen auf starren Kunststoffen mit gleichmäßiger Zufuhr.

- Vorsichtshinweise: Kann absplittern, wenn das Ausgangsmaterial häufigen harten Stößen oder Metalleinschlüssen ausgesetzt ist.

T2 - Der zweite Tag

- Stärke: sehr hohe Verschleißfestigkeit, insbesondere unter abrasiven Bedingungen.

- Am besten geeignet für: abrasive/schmutzige Materialien und gefüllte Kunststoffe (z. B. mit Glasfaseranteil).

- Vorsichtshinweise: mittlere Zähigkeit; Priorität haben ordnungsgemäße Reinigung und Kontaminationskontrolle.

DC53

- Stärke: gutes Gleichgewicht zwischen Verschleißfestigkeit und Zähigkeit.

- Am besten geeignet für: Gemischte Kunststoffe, PVC und variable Rohstoffe, bei denen es zu Störungen kommt.

- Vorsichtshinweise: Die Leistungsfähigkeit hängt stark von der Wärmebehandlung und einer stabilen Betriebskonfiguration ab.

55SiCr

- Stärke: hohe Stoßdämpfung und Zähigkeit bei Stößen.

- Am besten geeignet für: Anwendungen, bei denen Absplitterungen die häufigste Ausfallursache sind.

- Vorsichtshinweise: typischerweise geringere Verschleißfestigkeit; erfordert möglicherweise häufigeres Schärfen in abrasiven Medien.

Wie man die richtige Klinge auswählt

1) Kunststoffart und Härte

Harte Kunststoffe und technische Polymere zeichnen sich oft durch Verschleißfestigkeit aus. Weichere Kunststoffe tolerieren zwar eine geringere Härte, benötigen aber Stabilität gegenüber Stößen.

2) Schleifmittel und Verunreinigungen

Glasfasern, mineralische Füllstoffe, Sand/Schmutz und verschmutzte Ströme führen zu schnellem Verschleiß der Kanten – je nach Belastung sollte D2/SKD-11 oder DC53 bevorzugt werden.

3) Stoßbelastungen

Harte Einschlüsse und ungleichmäßiger Vorschub können zu Ausbrüchen an den Schaufeln führen – daher sollte die Zähigkeit (DC53 oder 55SiCr) Priorität haben und die Kontaminationskontrolle verstärkt werden.

4) Ausgabegröße und Durchsatz

Hoher Durchsatz erhöht Wärme und Belastung. Stellen Sie sicher, dass die Stahlsorte Ihrem Betriebszyklus und Ihren Wartungsintervallen entspricht.

Praktischer Ansatz: Bei der Verarbeitung von Kunststoffgemischen empfiehlt sich DC53. Bei der Verarbeitung von abrasiven Kunststoffen ist D2/SKD-11 die beste Wahl. Bei überwiegendem Abplatzen sollte 55SiCr in Betracht gezogen werden.

Tipps zur Verlängerung der Klingenlebensdauer

- Kontamination kontrollieren: Metall und Steine können flussaufwärts nach Möglichkeit entfernt werden.

- Freiraum gewährleisten: Ein falscher Messerspalt beschleunigt den Verschleiß und erhöht die Leistungsaufnahme.

- Halten Sie die richtigen Schärfintervalle ein: Vermeiden Sie es, Klingen vollständig abzustumpfen – dies erhöht das Risiko von Hitzeentwicklung und Verformung.

- Rotordrehzahl an Material anpassen: Zu schnelles Beschleunigen führt zu erhöhter Hitze; zu langsames Beschleunigen kann die Stoßbelastung erhöhen.

- Verschleißdaten aufzeichnen: Verfolgen Sie die Tonnage zwischen den Schleifvorgängen, um die beste Körnung für Ihren Materialstrom auszuwählen.

Welche Aktenvernichter verwenden diese Klingen?

Diese Klingenmaterialien werden häufig in Einwellen- und Zweiwellenzerkleinerern sowie in Kunststoffbrechern eingesetzt, die Hartkunststoffe, Folien, Gewebesäcke, Rohre und gemischte Abfallströme verarbeiten. Die optimale Qualität hängt von der jeweiligen Anwendung und der Maschinenkonstruktion ab.

Hier finden Sie Modelle und Anwendungsbereiche für Kunststoffschredder: Kunststoffzerkleinerer.

Häufig gestellte Fragen

Ist SKD-11 dasselbe wie D2?

Es handelt sich um eng verwandte Werkzeugstähle, die in der Industrie häufig verglichen werden. Die Leistungsfähigkeit hängt von der Wärmebehandlung, den Härtevorgaben und der Schnittgeometrie ab.

Welcher Klingenstahl eignet sich am besten für PVC?

DC53 wird häufig für PVC und Mischströme gewählt, da es Verschleißfestigkeit und Zähigkeit unter variablen Bedingungen ausbalanciert.

Warum splittern Klingen selbst bei “hartem” Stahl?

Absplitterungen sind in der Regel auf ein Problem der Härte/Schlagfestigkeit zurückzuführen: harte Einschlüsse, Metallverunreinigungen, falsches Spiel oder übermäßige Stoßbelastungen.

Sprechen Sie mit einem Ingenieur

Die Leistung der Schneidmesser hängt von der Kunststoffart, dem Verschmutzungsgrad, dem Durchsatz und der Maschinenkonfiguration ab. Wenn Sie uns Fotos Ihres Materials, die gewünschte Ausgabegröße und das Modell Ihres Zerkleinerers oder Brechers mitteilen, kann Ihnen das Energycle-Team den am besten geeigneten Schneidmesserstahl und ein Wartungsintervall empfehlen, um eine optimale Maschinenverfügbarkeit zu gewährleisten.

Um die richtige Sägeblattgüte empfehlen zu können, geben Sie bitte Folgendes an:

- Kunststoffart und Fotos (sauber vs. schmutzig, Füllstoffe, Etiketten, Metallrisiko)

- Zielkapazität (kg/h) und Betriebsstunden/Tag

- Maschinentyp (Einwellen-, Zweiwellen-, Brechermaschine) und Modell

- Zielausgabegröße und Bildschirm (falls zutreffend)