La tua guida definitiva alle attrezzature ad alta efficienza per il riciclaggio della plastica!

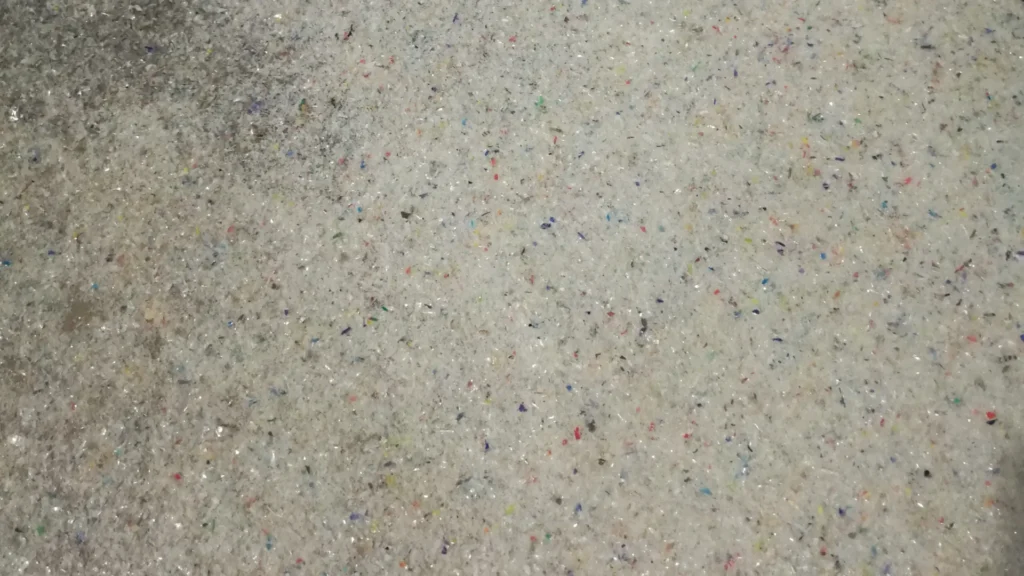

Pronti a dare una spinta al vostro riciclo della plastica? Scoprite la nostra analisi dettagliata dei macchinari essenziali che alimentano una linea di produzione di riciclo di alto livello! Dai robusti nastri trasportatori e potenti granulatori agli efficienti separatori e alle avanzate vasche di lavaggio, abbiamo le specifiche di cui avete bisogno. Questa configurazione, con una potenza installata totale di 310 kW e una capacità produttiva di 1.000-1.500 kg all'ora, è progettata per prestazioni di punta. È la roadmap perfetta per le aziende che desiderano ottimizzare le proprie operazioni di riciclo della plastica e fare davvero la differenza!

Specifiche dettagliate dell'attrezzatura

| Descrizione della macchina | Specifiche | Quantità (pezzo) |

|---|---|---|

| 1. Nastro trasportatore 1 | 1) Larghezza della cinghia: 800㎜ 2) Materiale della cinghia: PVC 3) Potenza motore: 2,2 kW 4) Rapporto di riduzione: 1: 30 5) Diametro del rullo di guida: φ273㎜ 6) Velocità lineare della cinghia: 0,63 m/s 7) Diametro del rullo condotto: φ323㎜ |

1 |

| 2. Granulator | 1) Motore principale: 45KW 2) Diametro di rotazione della testa di taglio: φ630㎜ 3) Larghezza della testa di taglio: 1150㎜ 4) Numero di coltelli rotanti: 10 pezzi 5) Numero di coltelli di partenza: 4 pezzi 6) Materiale della fresa: SKD11 7) Velocità di rotazione della testa di taglio: 462 giri/min 8) Materiale della testa di taglio: acciaio 45 9) Maglia dello schermo: φ95㎜ 10) Tramoggia di alimentazione aperta idraulica/cambiafiltro idraulico 11) Potenza della stazione idraulica: 2,2KW 12) Capacità: 1000-1200 kg/h 13) Potenza di trasmissione: 3KW 14) Modello riduttore: NMRV130-30 15) Velocità di rotazione del trasportatore a coclea: regolabile da 20 a 72,5 giri/min 16) Diametro delle pale della vite: φ250㎜ 17) Spazio per le viti: 200㎜ 18) Materiale della vite: acciaio inossidabile |

1 |

| 3. Trasportatore a coclea 1 | 1) Potenza motore: 3,7 kW 2) Velocità di rotazione del trasportatore a coclea: 20-72,5 giri/min 3) Diametro delle pale della vite: φ390㎜ 4) Corsa della vite: 300㎜ 5) Materiale della vite: acciaio inossidabile 6) Materiale del telaio: acciaio al carbonio |

1 |

| 4. Separatore di film e scaglie | 1) Materiale: acciaio inossidabile 2) Materiale del telaio: acciaio al carbonio |

1 |

| 5. Sistema di invio del vento | 1) Motore del ventilatore: 5,5 kW 2) Diametro del tubo: φ159㎜ 3) Materiale del tubo: acciaio inossidabile |

1 |

| 6. Conservazione delle etichette | 1) Materiale di stoccaggio: acciaio inossidabile 2) Volume: 2m³ |

1 |

| 7. Trasportatore a coclea 2 | 1) Potenza motore: 3,7 kW 2) Velocità di rotazione del trasportatore a coclea: 20-72,5 giri/min 3) Diametro delle pale della vite: φ390㎜ 4) Corsa della vite: 300㎜ 5) Materiale della vite: acciaio inossidabile 6) Materiale del telaio: acciaio al carbonio |

1 |

| 8. Vasca di lavaggio | 1) Larghezza interna: 1500㎜ 2) Lunghezza totale: 5000㎜ 3) Materiale: acciaio inossidabile 4) Materiale del telaio: acciaio al carbonio 5) Motore della coclea inferiore: 5,5 kW 6) Motore della coclea di scarico del materiale: 3,7 kW 7) Potenza motore coclea di sollevamento: 3KW 8) Potenza motore principale: 3KW |

2 |

| 9. Lavatrice a caldo (caldaia) | 1) Potenza motore: 7,5 kW 2) Modello riduttore: BLD5-71-7.5 3) Velocità di rotazione dell'albero di agitazione: 20 giri/min 4) Potenza termica: 60KW 5) Materiale della caldaia: acciaio inossidabile 6) Potenza di trasmissione: 3,7 kW 7) Modello riduttore: NMRV110-20 8) Velocità di rotazione della vite: 20-72,5 giri/min, regolabile 9) Diametro delle pale della vite: φ290㎜ 10) Distanziatore per viti: 200㎜ 11) Materiale della vite: acciaio inossidabile |

2 |

| 10. Rondella di frizione ad alta velocità | 1) Diametro di rotazione del rotore: φ524㎜ 2) Materiale del rotore: acciaio al carbonio 3) Velocità di rotazione del rotore: 960 giri/min 4) Numero di pale del rotore: 24 pezzi 5) Corpo della lavatrice: acciaio inossidabile 6) Lunghezza effettiva di lavaggio: 2800㎜ 7) Potenza motore: 37KW 8) Angolo di trasporto: 15° 9) Metodo di trasmissione: trasmissione a cinghia |

1 |

| 11. Trasportatore a coclea 3 | 1) Potenza motore: 3,7 kW 2) Velocità di rotazione del trasportatore a coclea: 20-72,5 giri/min 3) Diametro delle pale della vite: φ390㎜ 4) Corsa della vite: 300㎜ 5) Materiale della vite: acciaio inossidabile 6) Materiale del telaio: acciaio al carbonio |

1 |

| 12. Macchina disidratatrice | 1) Potenza motore principale: 75KW 2) Materiale interno della macchina: acciaio inossidabile 3) Diametro di rotazione del rotore: φ850㎜ 4) Materiale del rotore: acciaio al carbonio |

1 |

| 13. Essiccatore termico | 1) Diametro del tubo: φ159㎜ 2) Potenza del ventilatore: 5,5 kW 3) Materiale del tubo: acciaio inossidabile 4) Modello del soffiatore: 9-19 NO.4X55 5) Potenza termica: 30KW |

2 |

| 14. Separatore a ciclone | 1) Diametro del separatore: φ1000㎜ 2) Materiale: acciaio inossidabile |

1 |

| 15. Silo del prodotto finito | 1) Materiale del silo: acciaio inossidabile 2) Volume del silo: 2,5 m³ |

1 |

| 16. Quadro elettrico | Sistema di controllo centralizzato | 1 |

| Totale | Potenza installata: 310 kW Capacità: 1.000 – 1.500 kg/h |

Diamo inizio al tuo progetto!

Qui a Riciclaggio Rumtoo, forniamo uno standard eccellente Linee di lavaggio bottiglie PET Progettati per soddisfare le esigenze della maggior parte degli impianti di riciclaggio. Ma non ci fermiamo qui! Hai bisogno di qualcosa di unico? Siamo specializzati nella progettazione e installazione di impianti completi per il riciclaggio del PET, progettati su misura per la tua applicazione, i tuoi requisiti di capacità e le tue specifiche. Qualunque sia il tuo progetto, puoi contare su di noi per un servizio clienti di prim'ordine e una comunicazione chiara in ogni fase del processo. Siamo entusiasti di aiutarti a realizzare la tua visione di riciclaggio!